Novel constructional column concrete pumping system

A technology of concrete pumps and structural columns, which is applied in building construction, processing of building materials, and construction, and can solve problems such as inconvenient movement, inability to ensure the construction quality of structural column concrete, and inconvenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] Below in conjunction with accompanying drawing, the present invention will be further described:

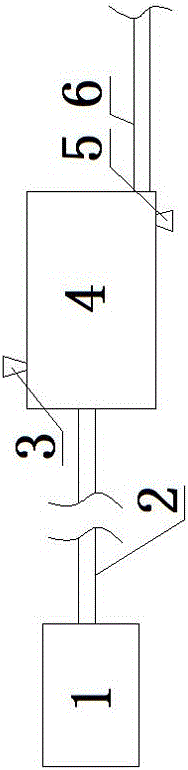

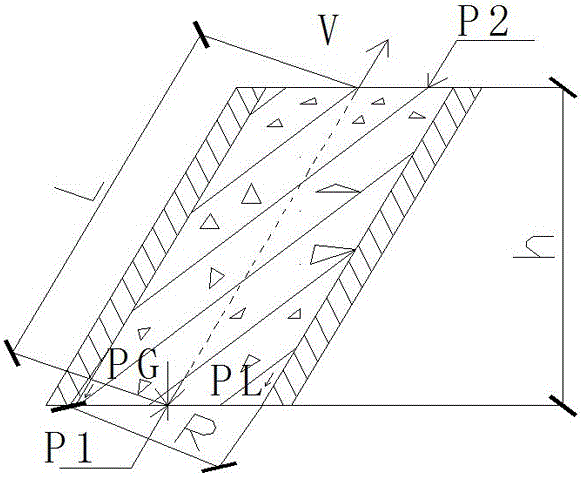

[0095] The new structural column concrete pumping system includes a pneumatic power device 1, the front end of a concrete storage container 4 connected to the pneumatic power device 1 through a power delivery pipe 2, and a concrete delivery pump pipe 6 is arranged under the rear end of the concrete storage container 4 The top of the concrete holding container 4 is provided with a flange cover-sealed feed port 3; the bottom is provided with a flange cover-sealed cleaning port 5; the feed port 3 is provided with a pressure relief device equipped with a ball valve;

[0096] Both the power delivery pipe 2 and the concrete delivery pump pipe 6 are welded with the concrete holding container 4 using seamless steel pipes; the pneumatic power device 1 includes an air compressor;

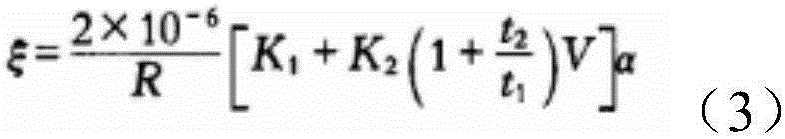

[0097] The specific construction method of the described structural column concrete pumping system is:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com