Diaphragm air pressure tank and processing technology thereof

A processing technology and air pressure tank technology, applied in the direction of climate change adaptation, climate sustainability, water saving, etc., can solve the problems of air leakage, water leakage, and the need to improve the sealing performance of the flange flange cover and the flange flange, etc. Achieve long service life, good air tightness and water tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

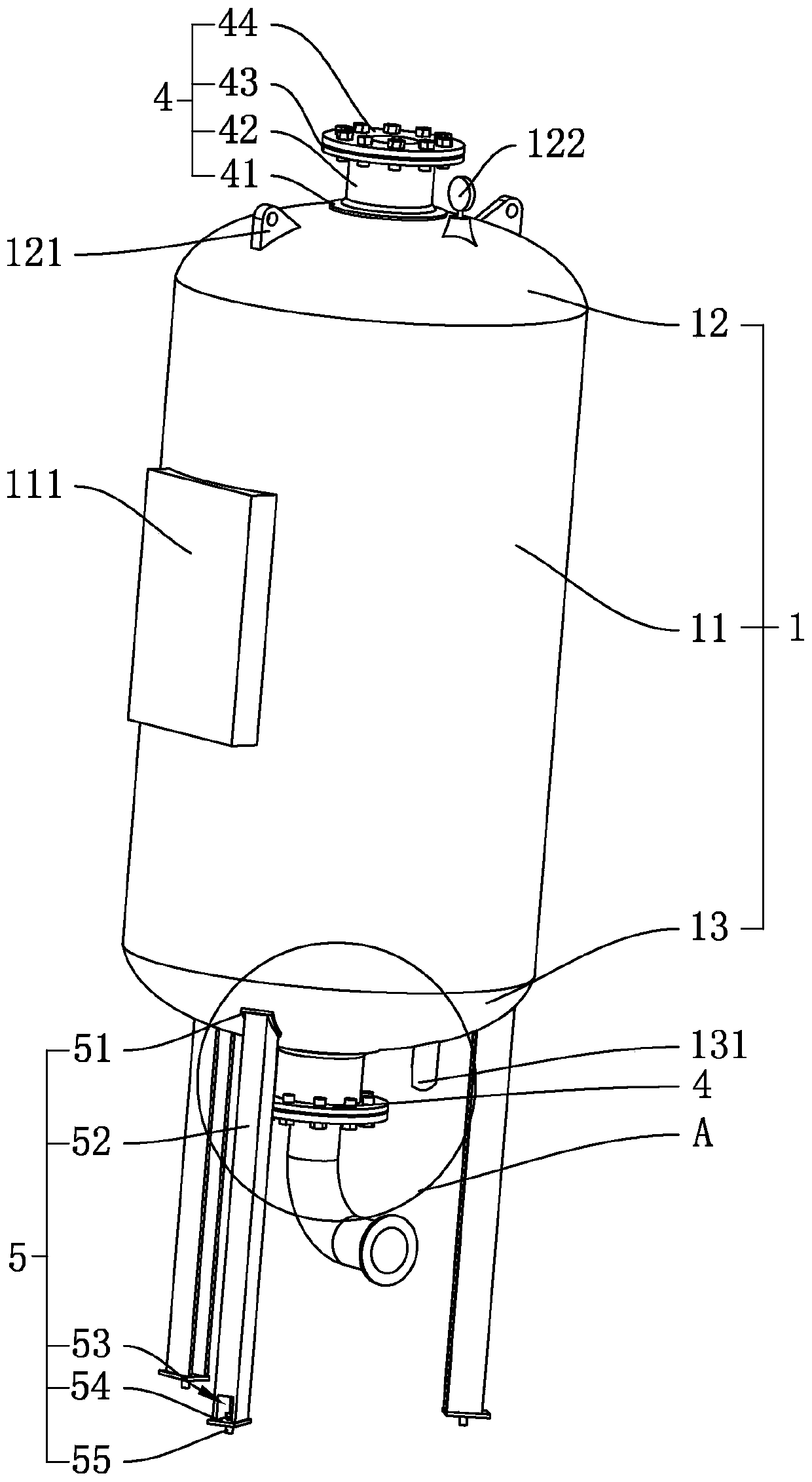

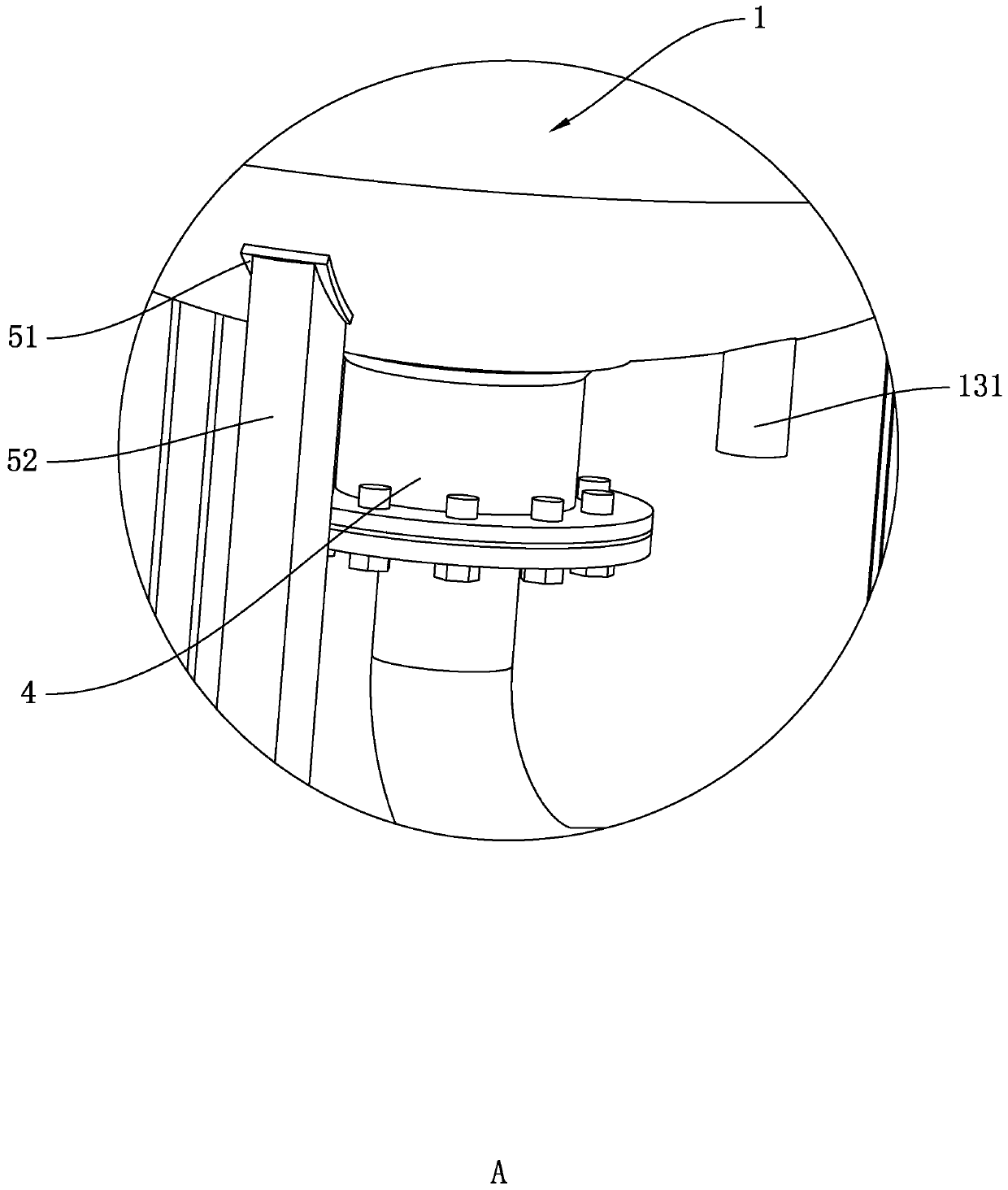

[0048] Example 1: Combining figure 1 and Figure 4 , is a diaphragm pressure tank disclosed by the present invention, comprising a steel gas tank body 1 and a rubber air bag 6, the volume of the rubber air bag 6 is smaller than that of the steel gas tank body 1, the rubber air bag 6 is located inside the steel gas tank body 1, and the steel gas tank body 1 A pressure chamber 7 is formed between the tank body 1 and the rubber airbag 6, and an inert gas is passed through the pressure chamber 7, and a water storage chamber 8 is formed inside the rubber airbag 6, and the steel gas tank body 1 is fixedly connected with bolts for fixing the rubber airbag 6. The fixed structure 4 is welded with several supporting structures 5 for supporting the steel gas tank body 1 at the bottom end of the steel gas tank body 1 .

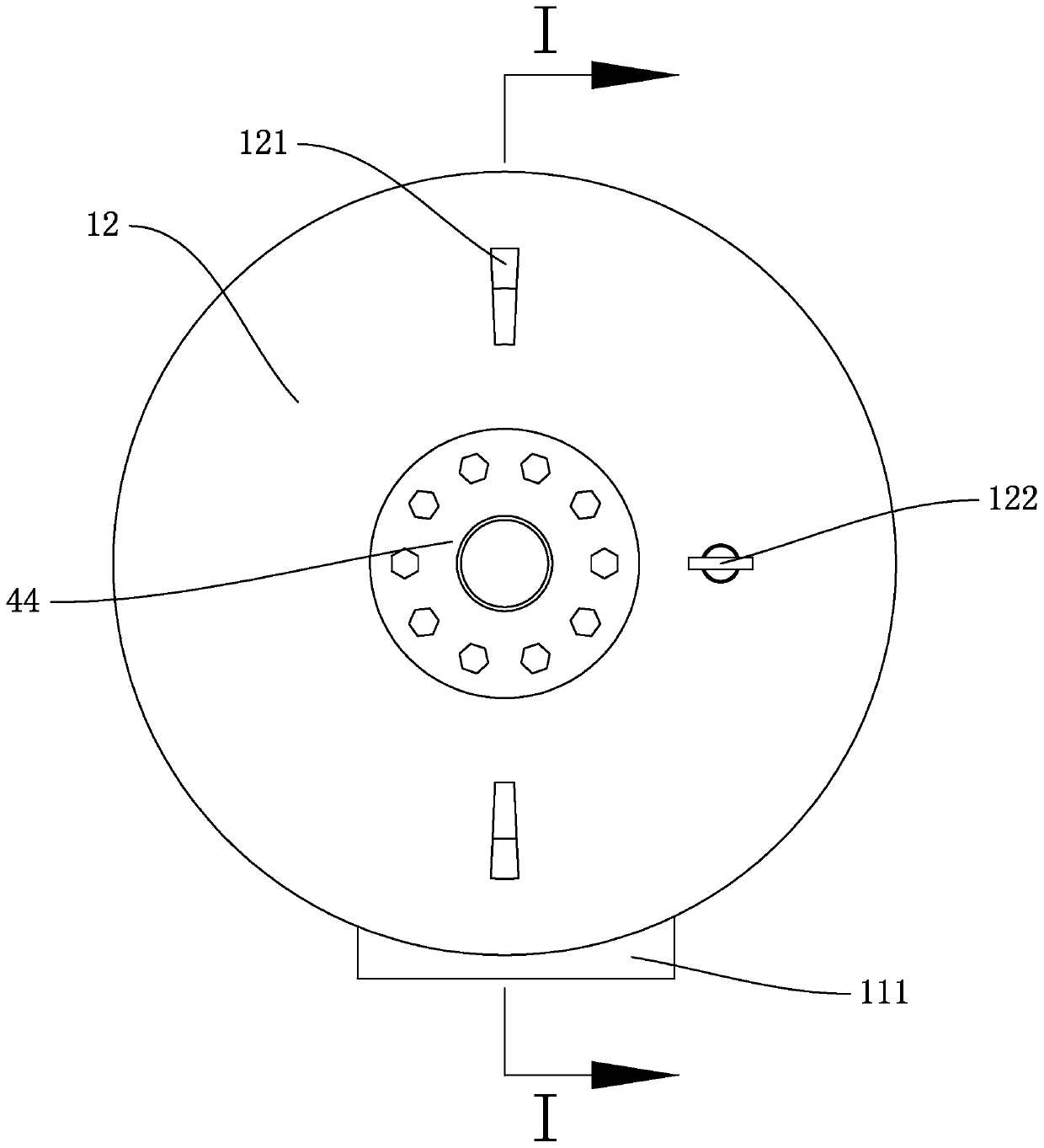

[0049] combine figure 1The steel gas tank body 1 comprises a tank body 11, an upper top cover 12 welded on the top of the tank body 11 and a lower bottom cover 13 welde...

Embodiment 2

[0059] Embodiment two: a kind of processing technique of diaphragm pressure tank, is used for producing embodiment one, and technological method comprises the following steps:

[0060] S1. Stamping two circular steel plates respectively to form an upper top cover 12 and a lower bottom cover 13;

[0061] S2. Bending the rectangular steel plate, and welding the edges in the length direction to form the tank body 11;

[0062] S3. welding the upper top cover 12 to the top of the tank body 11, and welding the lower bottom cover 13 to the bottom end of the tank body 11;

[0063] S4. Open round holes on the upper top cover 12 and the lower bottom cover 13 respectively, and weld the backing plate 41 at the round holes, weld the round pipe 42 on the backing plate 41, and weld the flange on the round pipe 42 43. Finally, the flange cover 44 is fixed on the flange plate 43 by bolts;

[0064] S5. Weld the support structure 5 on the lower bottom cover 13, install the upper air intake pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com