Thermocouple leading device

A technology for extracting devices and thermocouples, applied in the direction of using electrical devices, measuring devices, measuring heat, etc., can solve problems that affect the normal operation and use of equipment, air leakage, etc., and achieve the effect of solving sealing problems and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

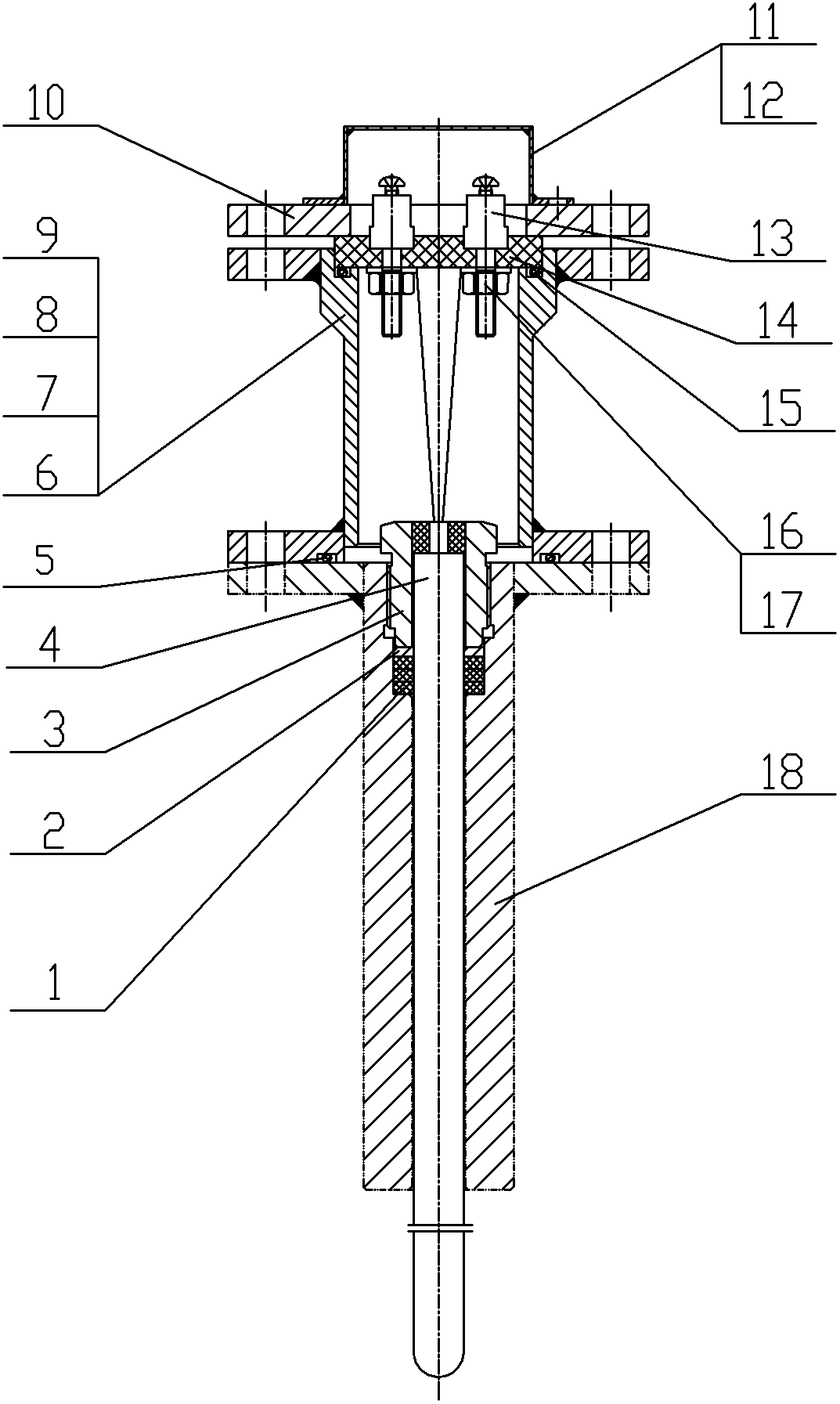

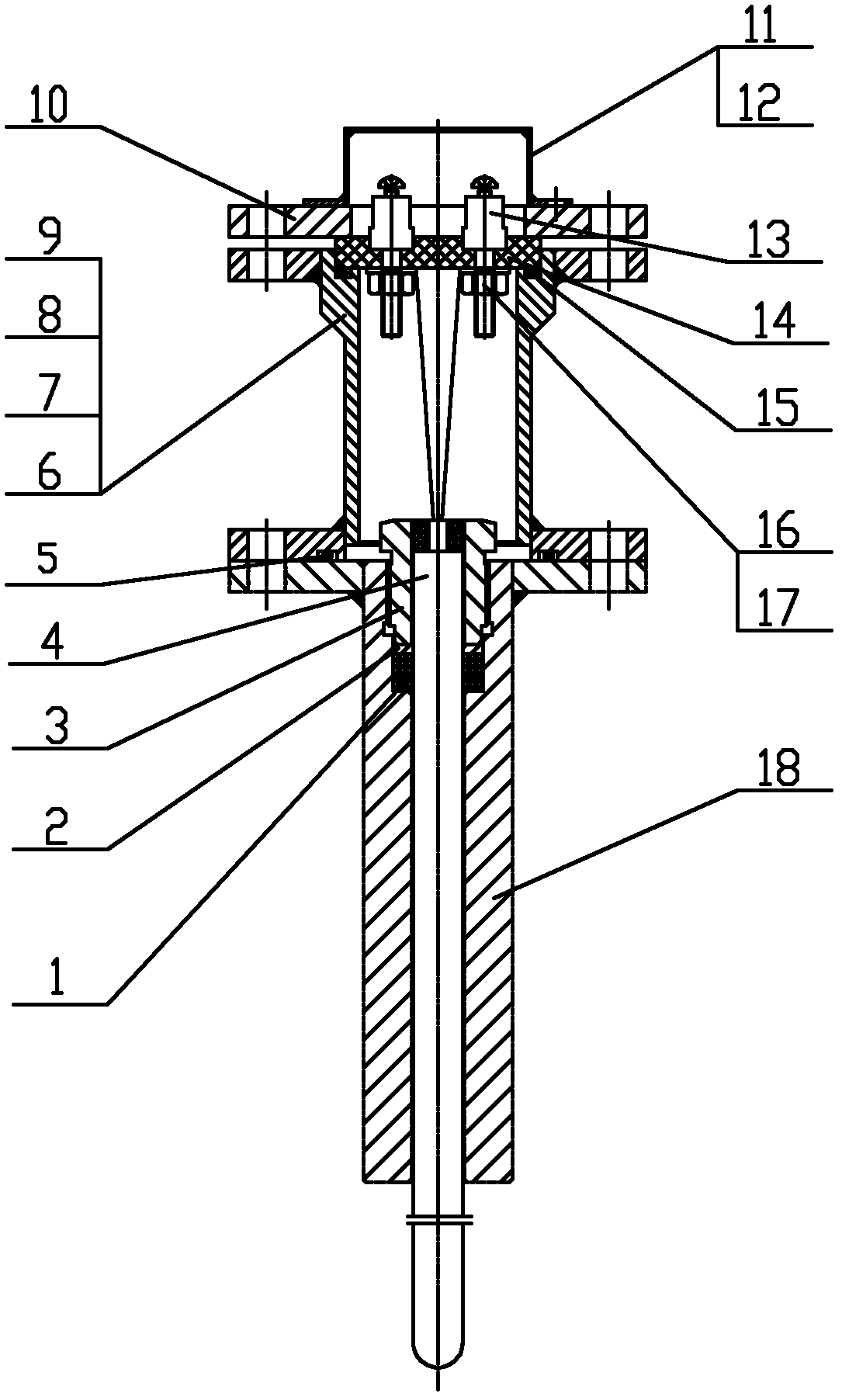

[0013] The present invention will be further described below in conjunction with specific drawings.

[0014] As shown in the figure: the thermocouple lead-out device includes a gasket 1, a pressure pad 2, a compression screw 3, a thermocouple 4, a first O-ring 5, a thermocouple connection seat 6, a hexagonal bolt 7, and a first hexagonal nut 8. First flat washer 9, flange cover 10, protective cover 11, cross recessed pan head screw 12, terminal post 13, insulating seat 14, second O-ring 15, second hex nut 16, second flat Gasket 17 etc.

[0015] The present invention comprises a thermocouple connection base 6, a thermocouple 4 is installed at the lower end of the thermocouple connection base 6, an insulating seat 14 is arranged on the upper end of the thermocouple connection base 6, and a second hex nut 16 and a second A flat washer 17 is installed with a terminal post 13; the insulating seat 14 is covered with a flange cover 10 and a protective cover 11 fixed on the flange co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com