Pressure testing tool for opening connecting tubes without flange seal

A flange-free, pressure-testing technology, applied in the direction of applying stable tension/pressure to test material strength, using liquid/vacuum degree to measure liquid tightness, measuring devices, etc., can solve the problem of heavy welding workload and damage slope mouth, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

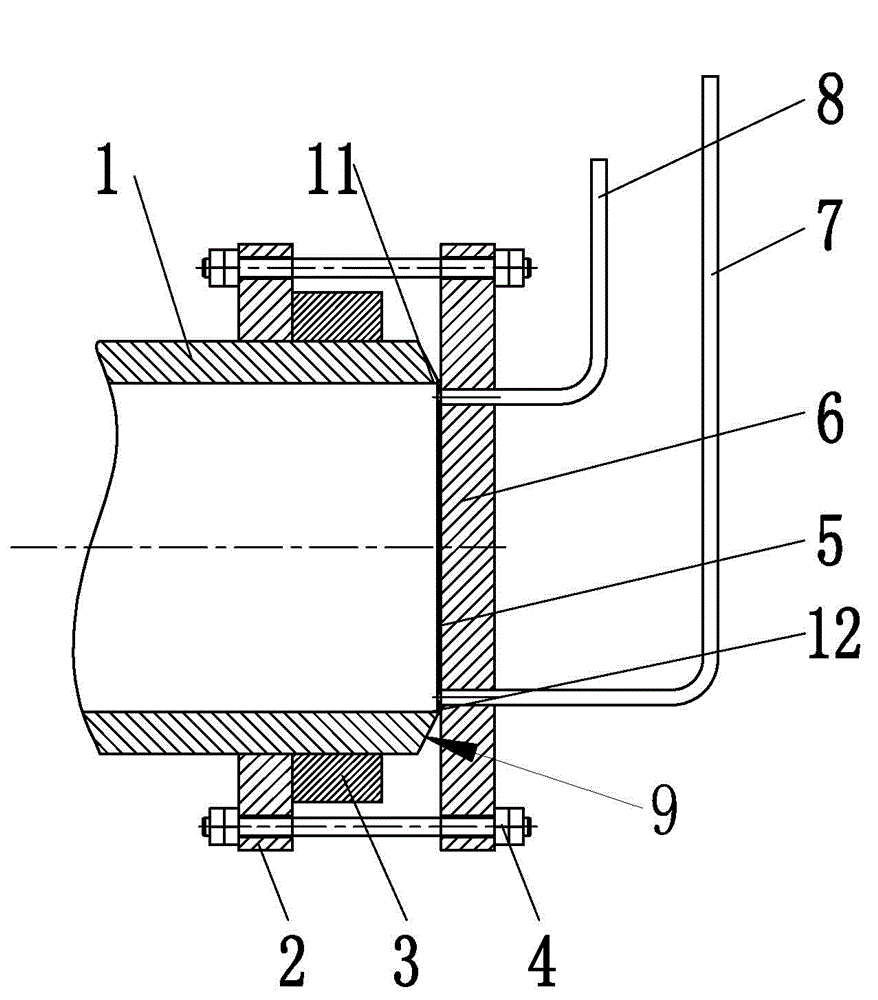

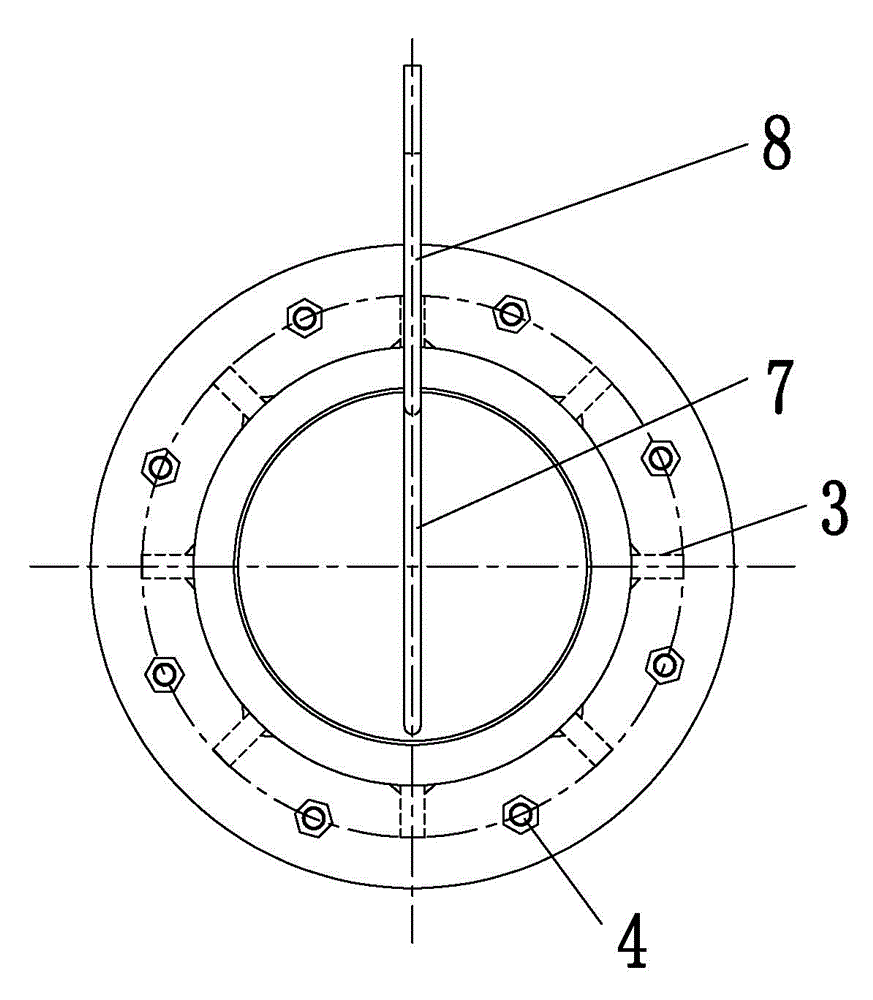

[0044] One of the specific implementations of a pressure test tool for an open joint without flange seal of the present invention, such as figure 1 and figure 2 shown, including:

[0045] The pressure test ring 2 is sleeved on the outer wall of the pipe 1;

[0046] The sealing thin plate 5 is welded to the nozzle;

[0047] The flange cover 6 is tightly crimped on the sealing sheet 5 and connected to the pressure test ring 2 through the locking member 4;

[0048] Exhaust pipe 8, one end of which is pierced through the flange cover 6 and the sealing sheet 5, and communicates with the inner cavity of the pipe 1, and the other end is bent upward;

[0049] The water inlet pipe 7, one end of which is pierced through the flange cover 6 and the sealing sheet 5, communicates with the inner cavity of the pipe 1, and the other end is bent upward;

[0050] A plurality of fixed ribs 3 are arranged along the circumference of the outer wall of the pipe 1 for supporting the pressure test...

Embodiment 2

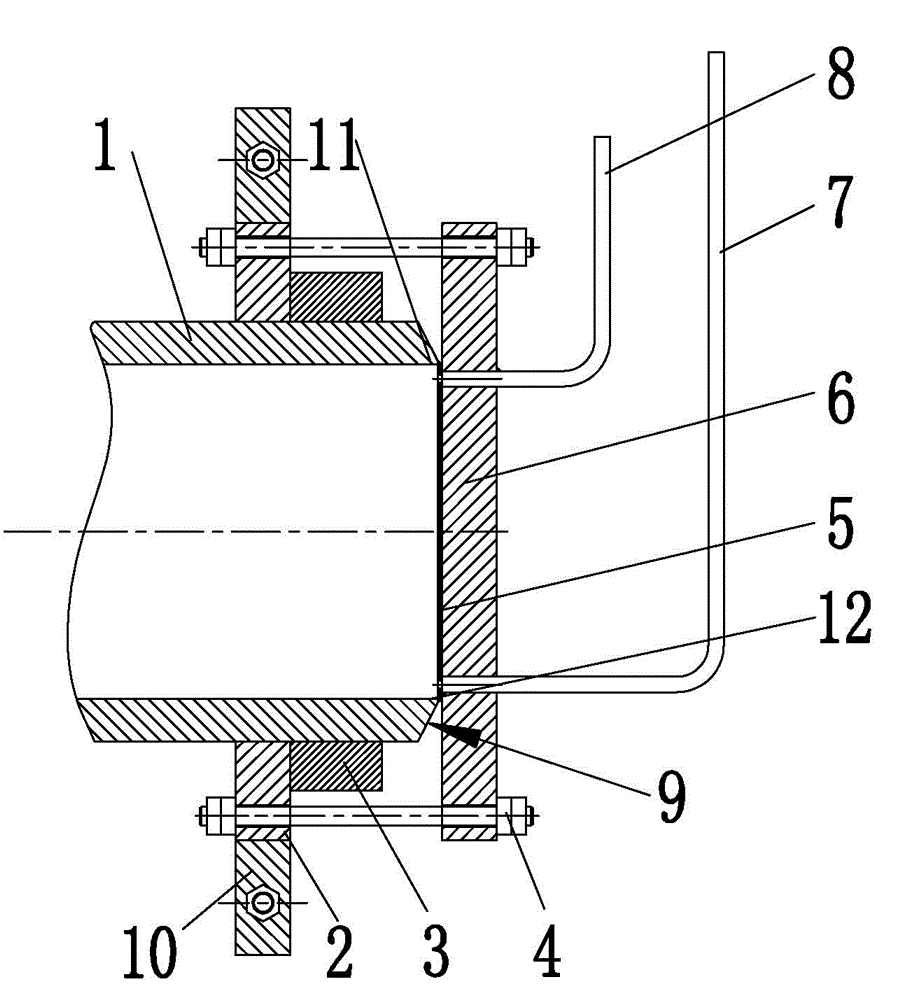

[0061] The second specific embodiment of the pressure test tooling for the open joint without flange seal of the present invention is as follows: image 3 and Figure 4 As shown, the main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is that the upper and lower parts of the pressure test ring 2 are provided with connecting plates 10 . Adding the connection plate 10 can be used for equipment that cannot use the pressure test ring 2 directly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com