Special testing device for small measuring chamber of nuclear power plant reactor cavity

A nuclear power plant reactor and test device technology, which is applied in the nuclear power plant reactor cavity measurement chamber, nuclear reactor facilities, and its special test device field, can solve the problems of no measurement chamber sealing test, etc., and achieve the effects of effective inspection, easy manufacture, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

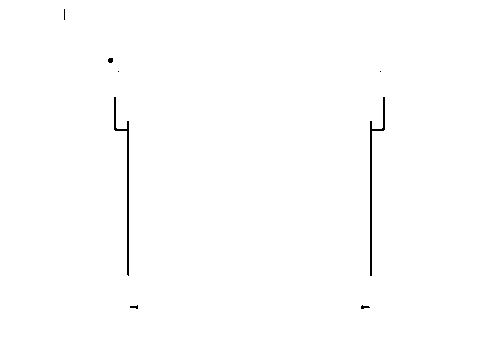

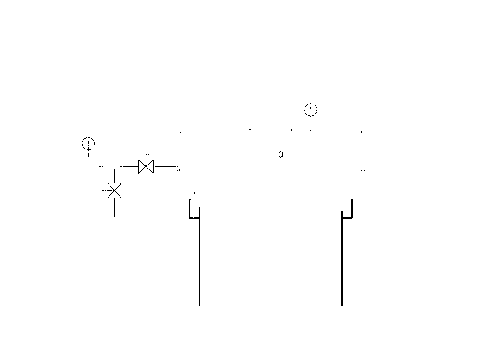

[0021] The measuring cell of the nuclear power plant reactor cavity of this embodiment is as follows: figure 1 As shown, the lower surface of the flange ring 10 is welded to the upper end of the support ring 3, and the lower end of the support ring 3 extends radially inward to extend the groove bottom ring 3-1. The upper part of the outer circle is welded and fixed, wherein the basket 2 is used to place the built-in neutron absorption plug, and the bottom of the basket 2 is the grille 1 . The inner hole of the flange ring 10 is a conical hole with an upper size and a lower size. One end of the flange cover 6 is hinged on one side of the upper surface of the flange ring 10 through the turning shaft 7, and the screw holes on the other side of the upper surface are provided with pressing bolts 4 pierced through the other end of the flange cover. The middle part of the flange cover 6 extends downward out of a ring-shaped truncated cone that matches the conical hole. The conical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com