Cast shell type EGR cooler

An EGR cooler, cooler technology, applied in indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the high reliability requirements of O-rings, thermal crack failure on the wall of the tube bundle, heat exchange tube bundles Surface dry burning and other problems, to ensure the uniformity of water flow, reduce the risk of thermal boiling, and increase the effect of water flow space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

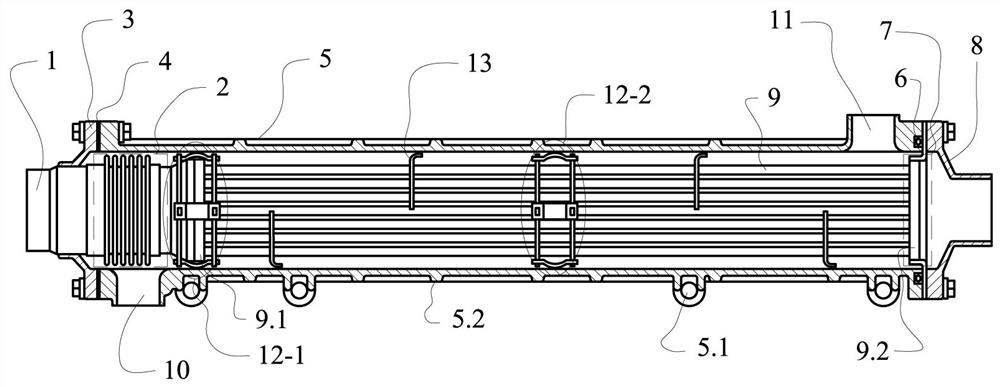

[0025] This embodiment is a cast shell type EGR cooler, such as figure 1 shown. This embodiment includes: an air intake joint 1, the air intake joint is connected to a double-layer telescopic structure 2 with a bellows and a casing, the outer circumference of the telescopic structure is fixedly connected to the flange cover 3 at the input end, the The input end flange cover described above is connected with one end bolt of the cast pipe shell 5 through the input end gasket 4, and the other end of the pipe shell is connected with the fixed structure 7 through the output end seal ring 6 and the output end method with the output pipe joint. The flange cover 8 is bolted; the telescopic structure is welded to the tube sheet 9.1 at one end of the tube bundle 9, and the tube sheet 9.2 at the other end of the tube bundle is welded to the fixed structure.

[0026] The intake joint is a device connected to the engine's exhaust pipe or EGR valve to input exhaust gas from the engine. In...

Embodiment 2

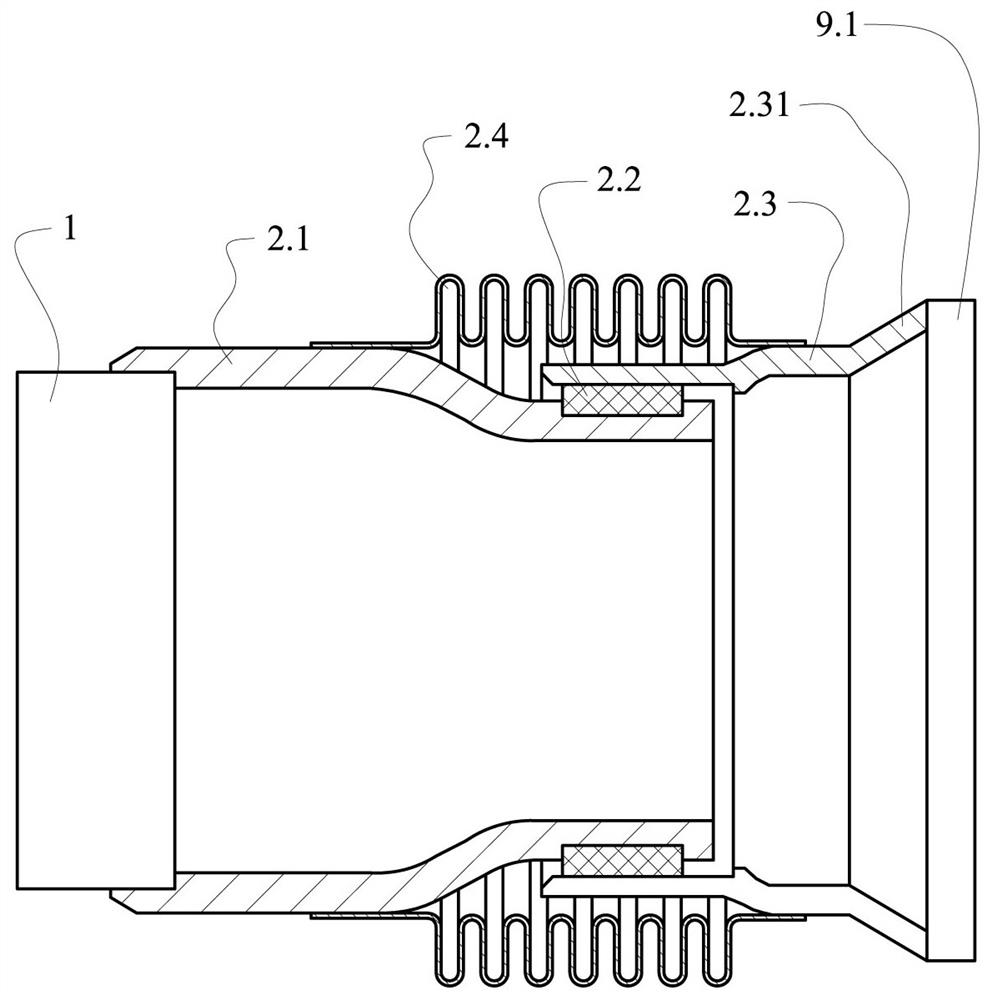

[0037] This embodiment is an improvement of the first embodiment, and is a refinement of the first embodiment on the telescopic structure. The telescopic structure described in this embodiment includes: a shrinking tube 2.1, the large end of the shrinking tube is welded to the intake joint, a slip ring 2.2 is fixed on the outer surface of the small end of the shrinking tube, and the The outer circular surface of the slip ring is slidably connected to the inner circular surface of the sliding tube 2.3, the sliding tube is provided with a flared diffuser section 2.31, the diffuser section is welded to the tube sheet of the tube bundle, the necked tube and Slide tube jacket bellows 2.4, eg figure 2 shown.

[0038] The necking tube is a guide tube that directs the incoming hot air to the tube bundle. The necking tube can be provided with an assembly groove for installing a slip ring, and the slip ring can be a ceramic ring with two half-ring structures, and the slip ring and th...

Embodiment 3

[0041] This embodiment is an improvement of the above embodiment, and is a refinement of the slip ring in the above embodiment, and the slip ring described in this embodiment is a ceramic ring.

[0042] Ceramics have good impact resistance and heat resistance, and are ideal materials for heat insulation and sliding surfaces. The ceramic ring described in this embodiment can play a role of radial support for the heat exchange core, and at the same time, the surface roughness of the ceramic ring is low, the coefficient of sliding friction is small, and the frictional resistance to the axial displacement of the heat exchange core is relatively low. Small, it will not affect the displacement compensation function of the double-layer bellows, and ensure the thermal shock resistance and vibration resistance of the overall structure of the cooler.

[0043] There is a ceramic ring assembly groove in the necking tube, and the ceramic ring is a semi-ring structure, there are two in tota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com