Precise filter

A precision filter and filter area technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of stable control of no water, affecting filtration efficiency, and wasting filtration area and other problems, to prevent short circuit and bias current phenomenon, to ensure the effect of treatment, and to facilitate installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

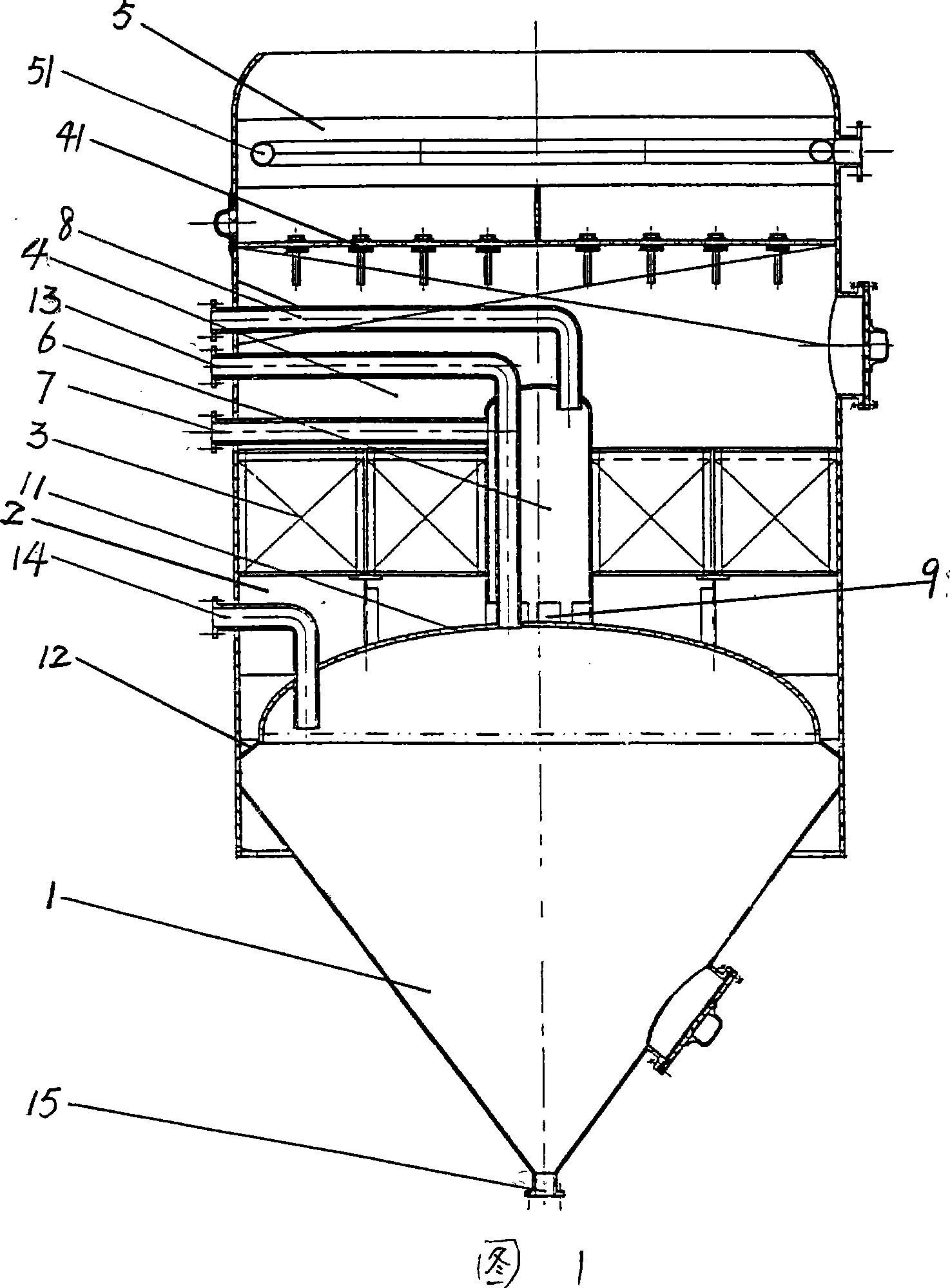

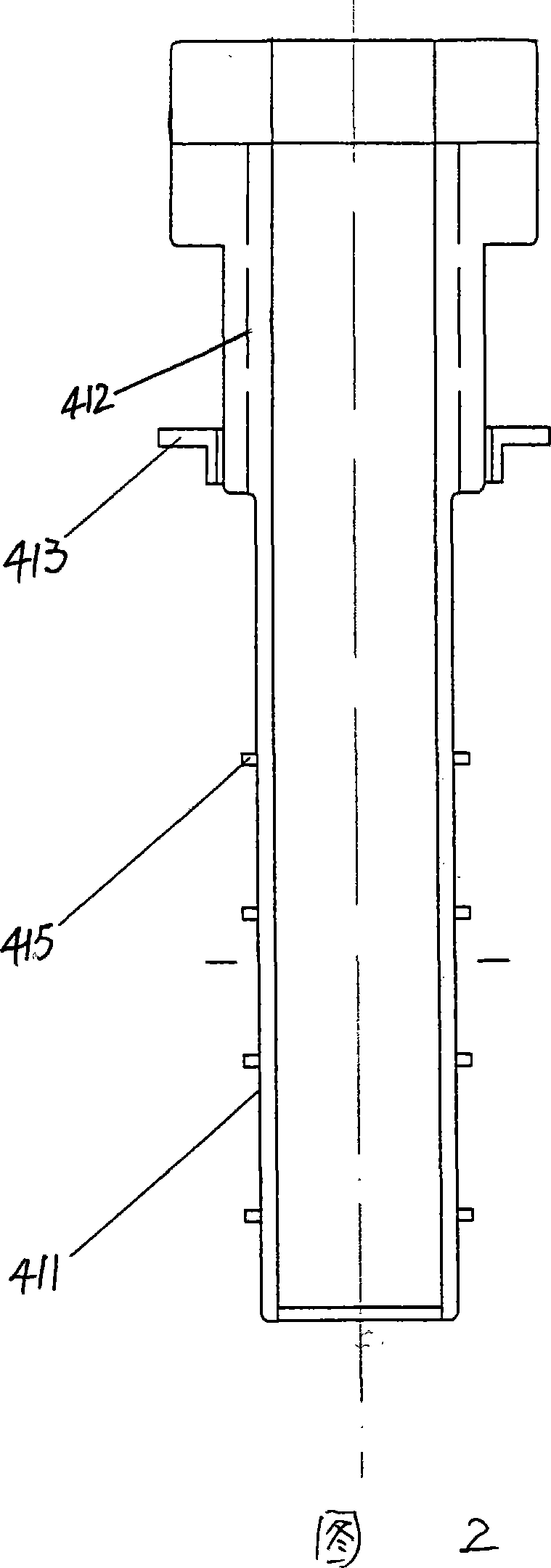

[0013] The precision filter includes a shell with an open top, and the shell is composed of mud collection area 1, flocculation area 2, sedimentation area 3, filtration area 4, and clear water area 5 from bottom to top:

[0014] The mud collecting area 1 is a conical mud collecting hopper, a flange cap 11 is placed on the top of the conical mud collecting hopper, and a regular slurry discharge system 15 is installed at the bottom of the conical mud collecting hopper. There is a muddy water inlet 12 connected to the flocculation area at the bucket port, an air inlet pipe 13 is connected to the top opening of the flange cap 11, and a return pipe 14 is also provided in the space of the flange cap of the conical mud collecting bucket;

[0015] The upper part of a central liquid inlet tank 6 is connected to the water inlet pipe 7, the top is connected to the exhaust pipe 8, and the bottom is fixed to the center of the flange cap 11, and a water outlet hole 9 is opened on the side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com