Compressor and air conditioner

A compressor and shaft technology, applied in the field of air conditioning, can solve the problems of increased wear of parts, poor stability of rotor compressors, and noise, and achieve the effects of reducing friction, reducing movement, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

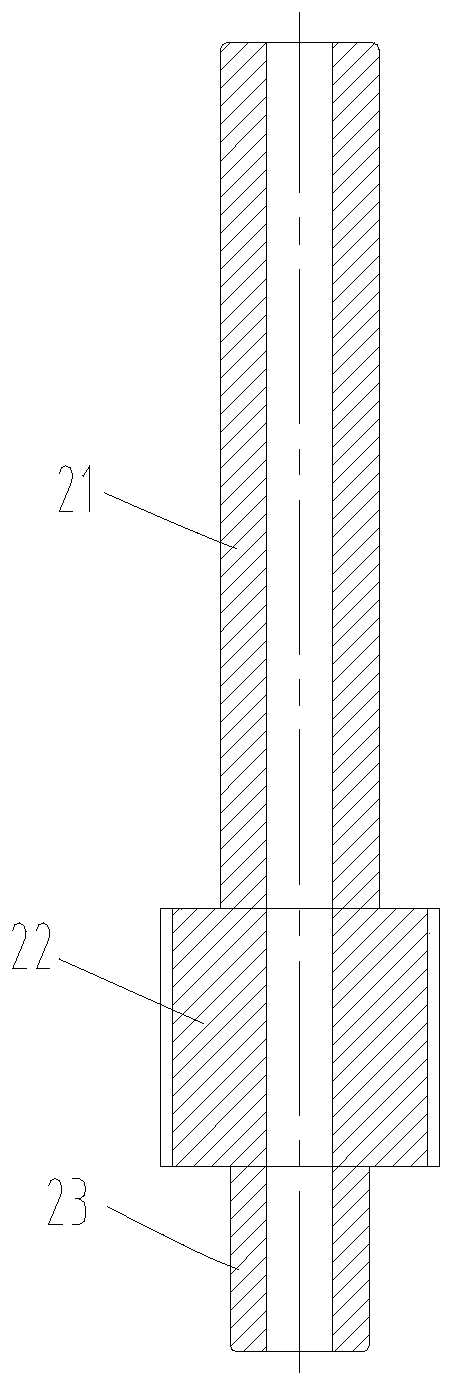

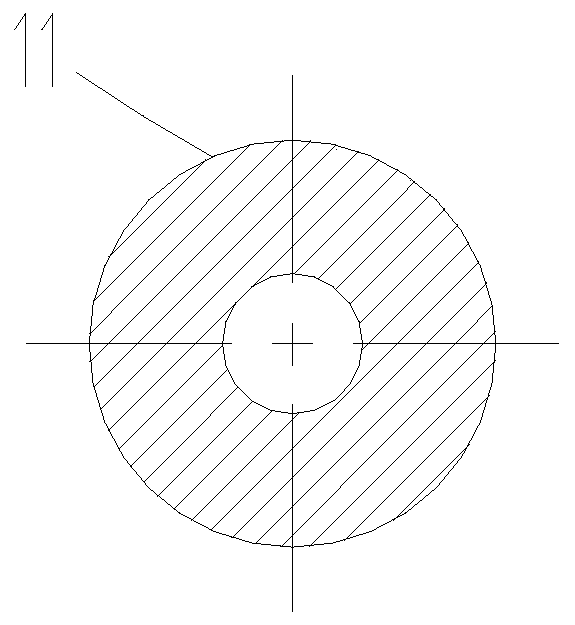

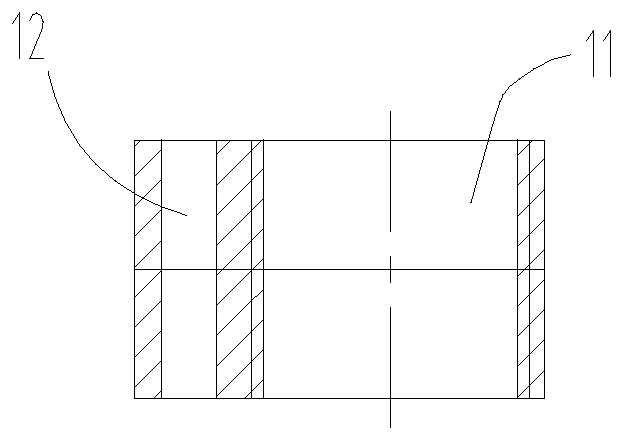

[0024] see in conjunction Figure 1 to Figure 5 As shown, according to the embodiment of the present application, a compressor includes a rotating shaft 2 and a cylinder 6, the rotating shaft 2 passes through the cylinder 6, and the first flange 4, the second flange 5 and the roller 1 are sleeved on the rotating shaft 2 , the roller 1 is located in the cylinder 6, the first flange 4 is set on the first end of the cylinder 6, the second flange 5 is set on the second end of the cylinder 6, the cylinder 6, the first flange 4 and the second The flange 5 limits the position of the roller 1, the roller 1 is provided with a first limiter, and the crankshaft is provided with a second limiter, and the first limiter cooperates with the second limiter to be able to The axis direction of the rotating shaft 2 fixes the rotating shaft 2 and the roller 1 . By setting the cylinder 6, the first flange 4 and the second flange 5 are arranged at both ends of the cylinder 6, and the roller 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com