Liquid tank liner connection

a technology for connecting pipes and liquid tanks, applied in the direction of linings/internal coatings, water heaters, packaging, etc., can solve the problems of cumbersome connection of replacement pipes and difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Throughout the following detailed description, the same reference numerals refer to the same elements in all figures.

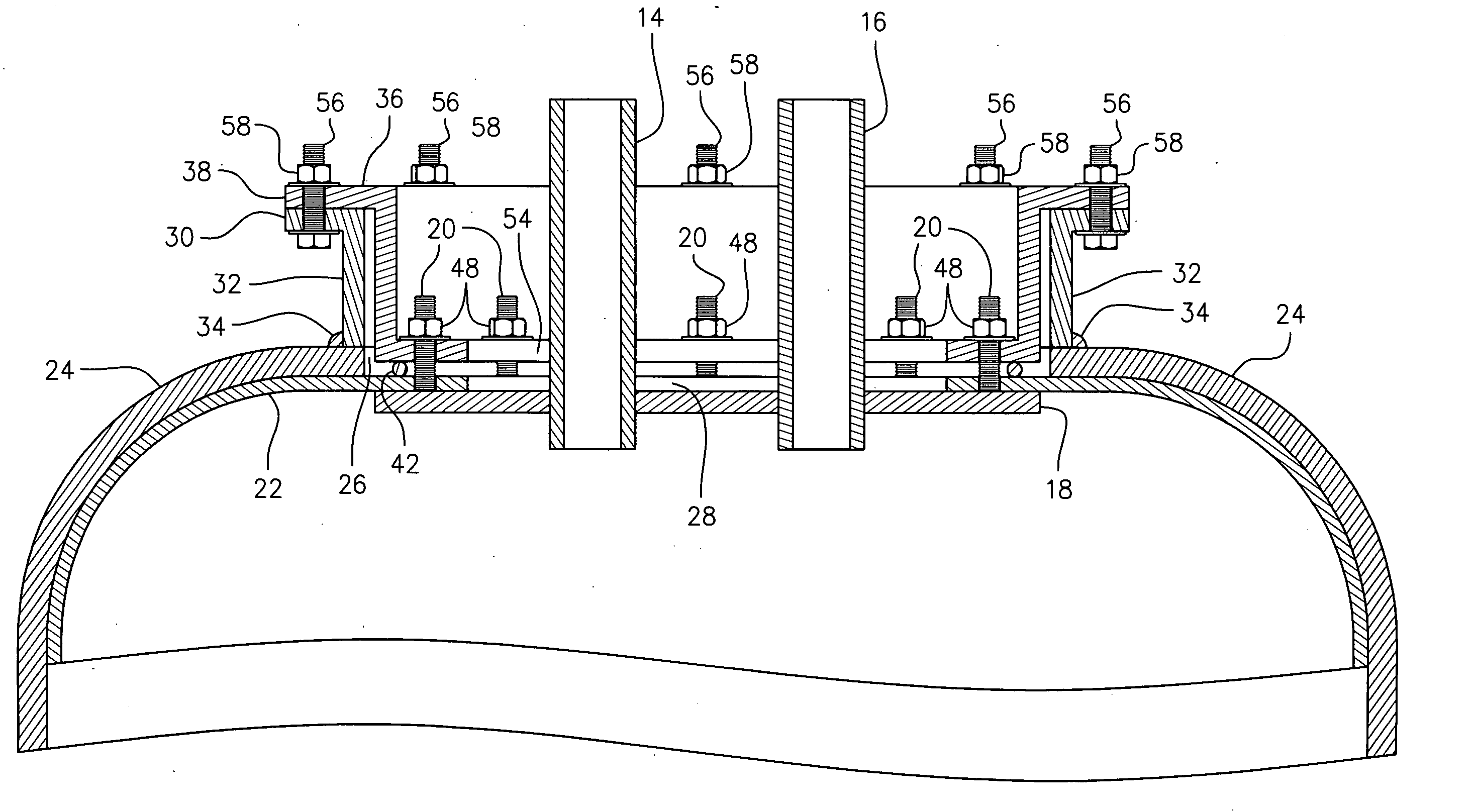

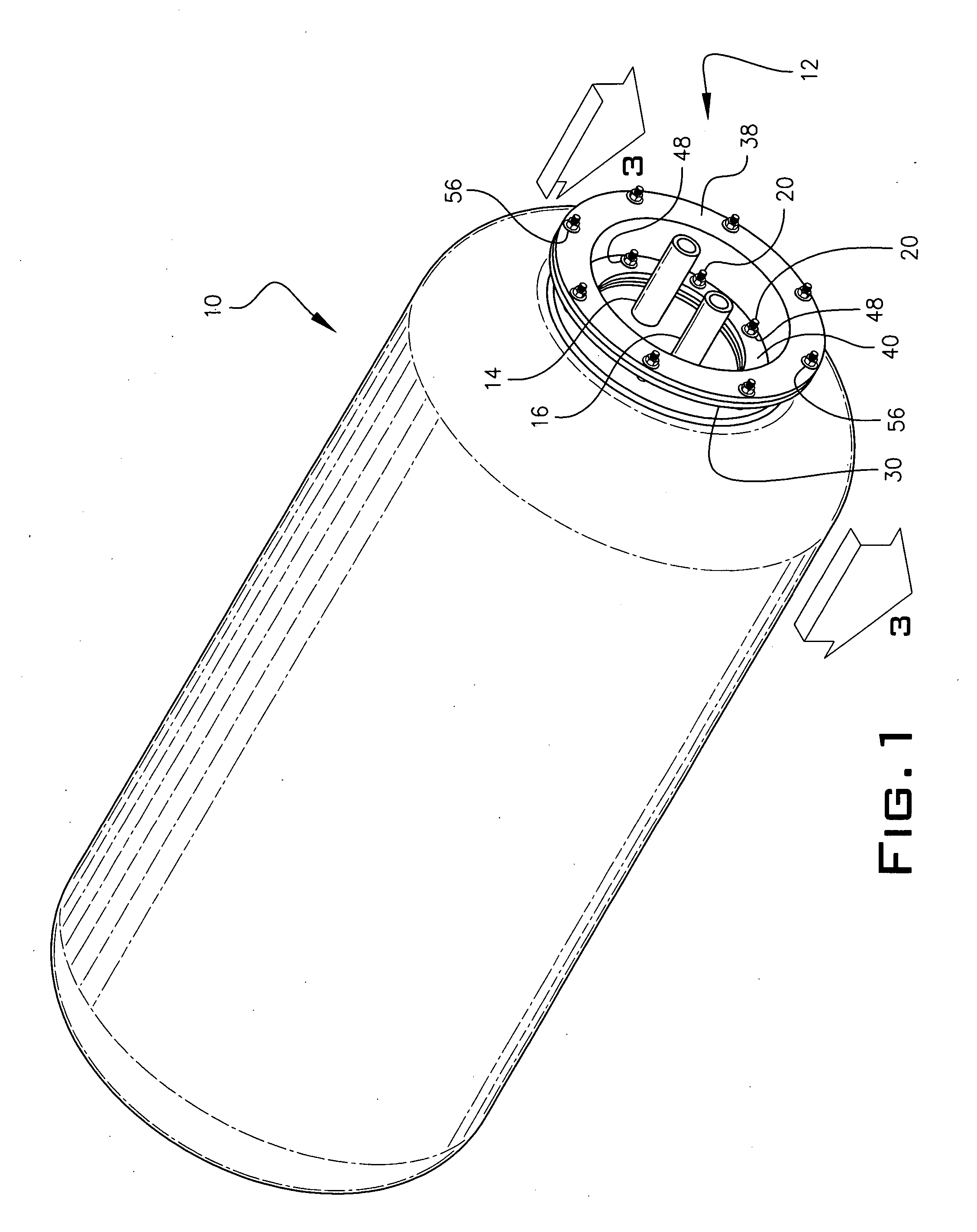

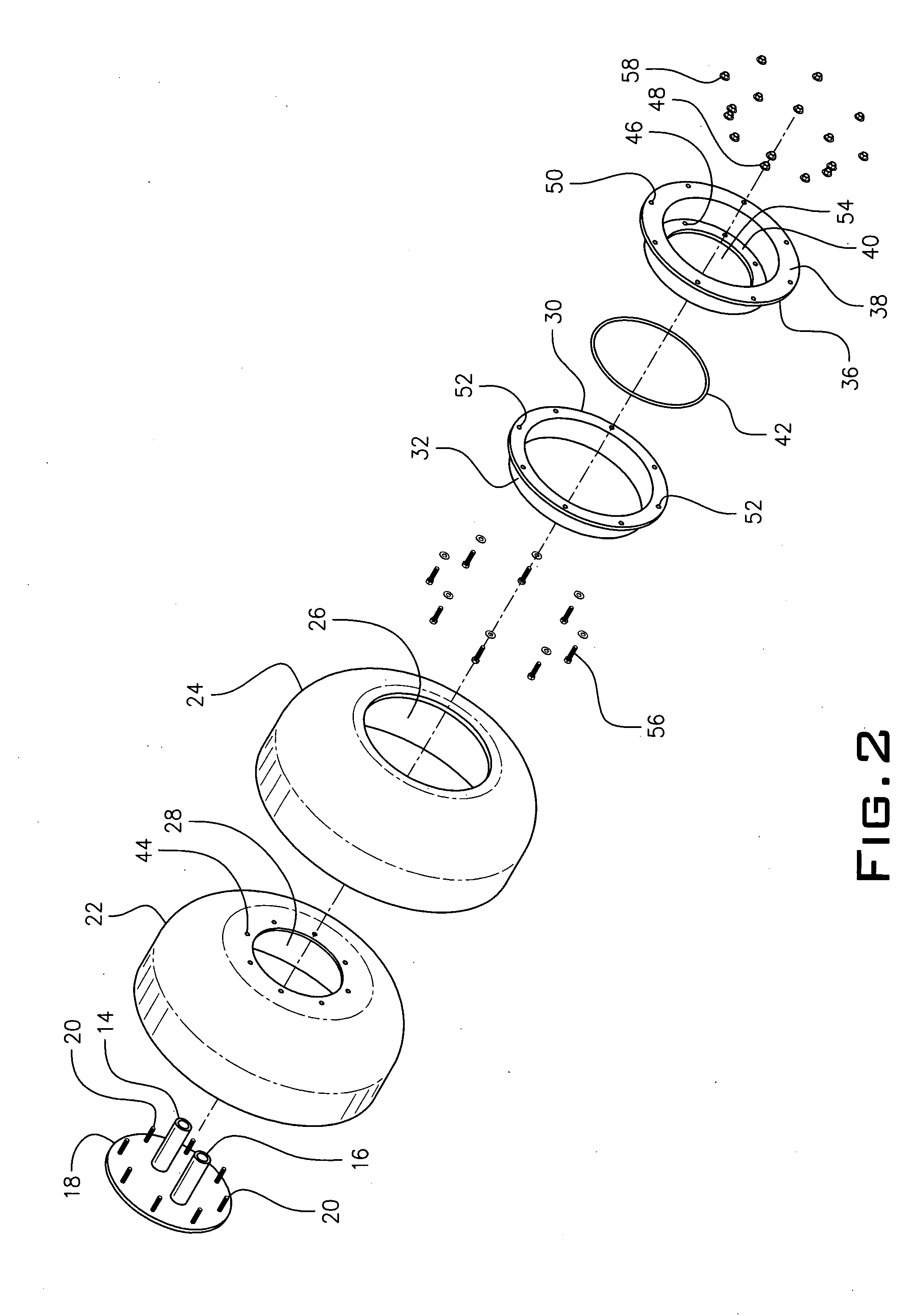

[0013] Referring to FIGS. 1 and 2, the tank 10 has a connection 12 to allow ingress and egress of a liquid to or from the tank through tubes 14 and 16 passing through plate 18 into the interior of the tank 10. Multiple threaded studs 20 project from plate 18. Additional tubes could pass through plate 18, if needed.

[0014] A top portion of liner 22 abuts an inside surface of tank head 24. The liner 22 has a central annular opening 28 that is aligned with, but smaller than, central annular opening 26 in tank head 24. A tank head flange 30 has a collar 32 that is welded 34 adjacent to annular opening 26.

[0015] As seen in FIG. 3, a flange cap 36 has an upper annular flange 38 integral with, but spaced apart from, a lower annular flange 40. An O-ring 42 is located between the lower annular flange 40 and the liner 22. Studs 20 mounted on flange plate 18 pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com