Bunsen burner using lean-rich combustion type

A burner, Bunsen technology, applied in the direction of gas fuel burners, burners, combustion types, etc., can solve the problems of backfire, unstable flame, increased gas flow rate of gas mixture, etc., to improve combustion performance, enhance flame Stabilizing function, the effect of reducing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

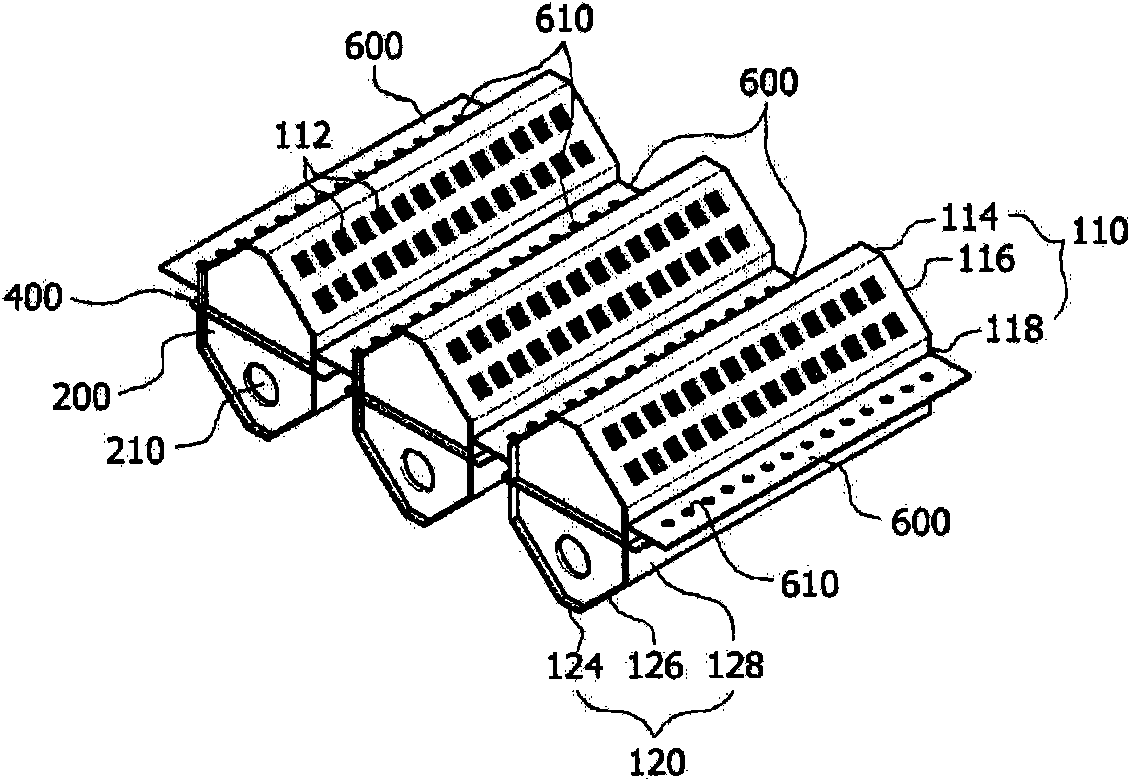

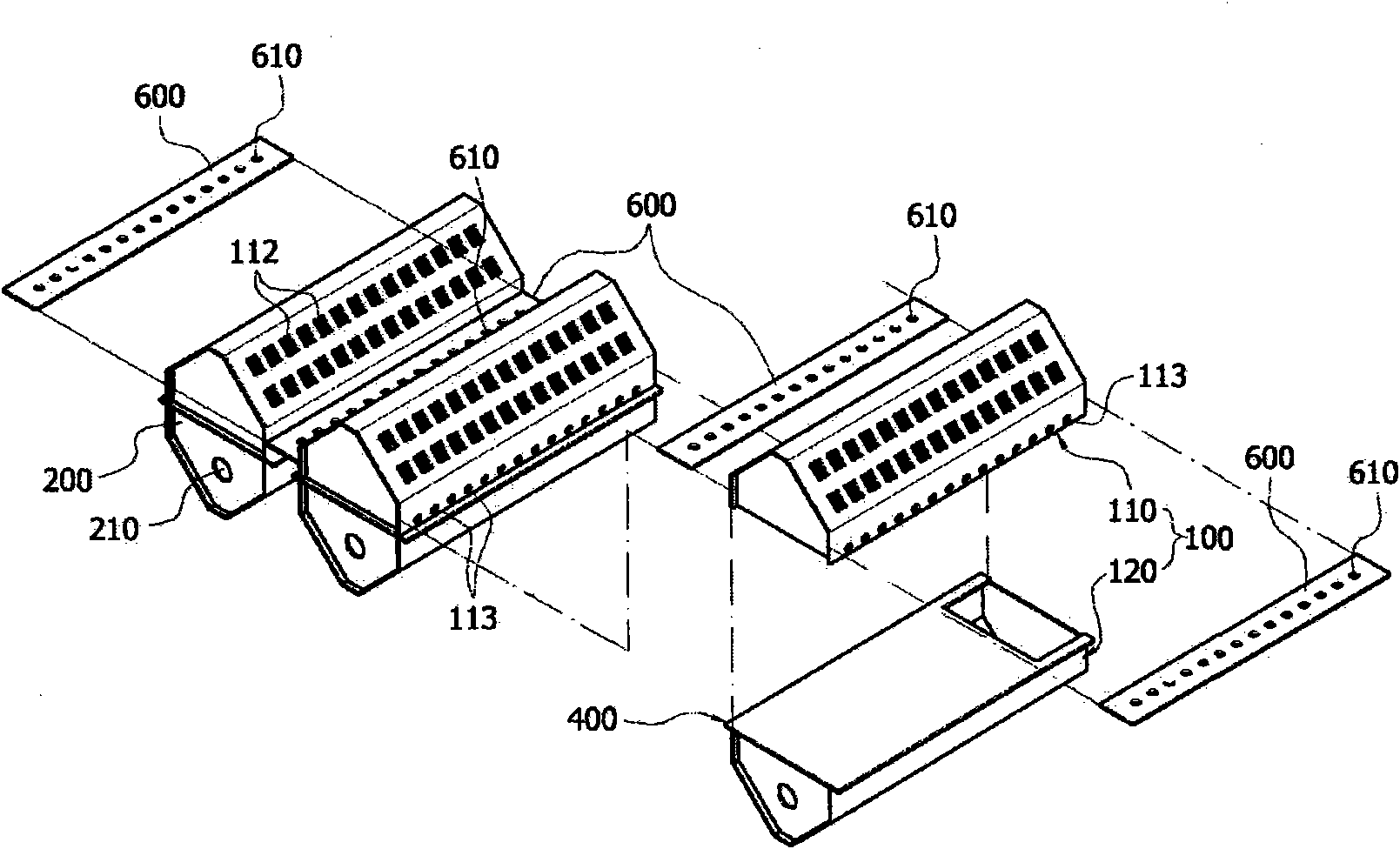

[0025] figure 1 is a side sectional view of a burner according to the invention. figure 2 is an assembled perspective view of the burner body and connecting plate according to the present invention. image 3 yes figure 2 An exploded perspective view of the burner body and connection plate shown.

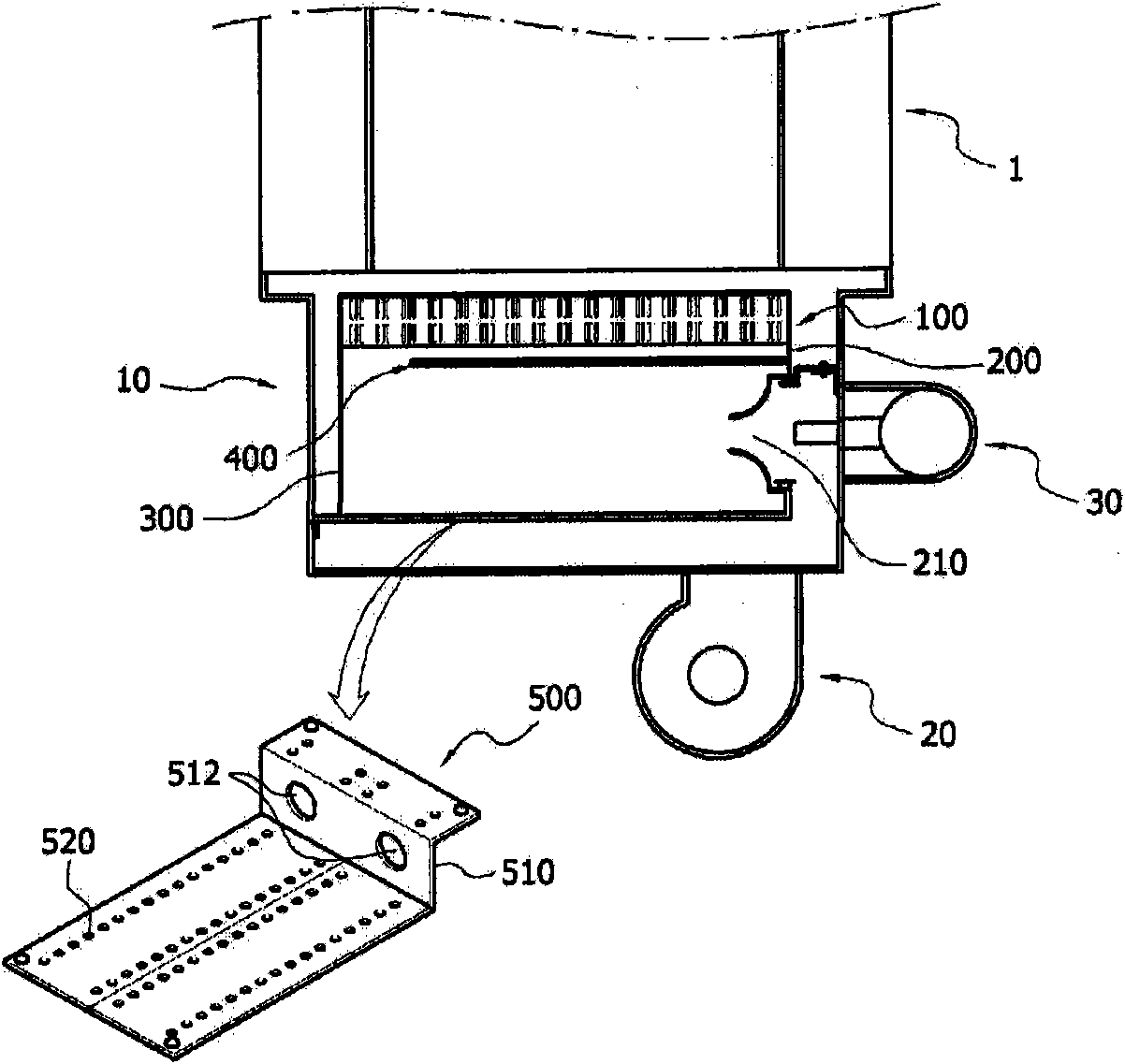

[0026] refer to figure 1 , the burner includes: a housing unit 10, an installation area is formed in the housing unit, and the components of the burner will be installed in the installation area; a fan 20 is connected and installed under the housing unit 10, so that the external Air is supplied into the housing unit 10; the nozzle unit 30 is connected and installed on one side of the housing unit 10, and has a front end portion located in the housing unit 10 to inject gas; the burner main body 100 is installed in the housing unit 10 insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com