Bunsen burner using lean-rich combustion type

a burner and lean technology, applied in the direction of burners, combustion types, combustion processes, etc., can solve the problems of unstable flames, increased airflow velocity of gas mixtures, back fires, etc., and achieve the effect of enhancing the stabilizing function of flames, reducing the width of burners, and easy supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]Hereinafter, example embodiments of the present invention will be described in detail with reference to the accompanying drawings.

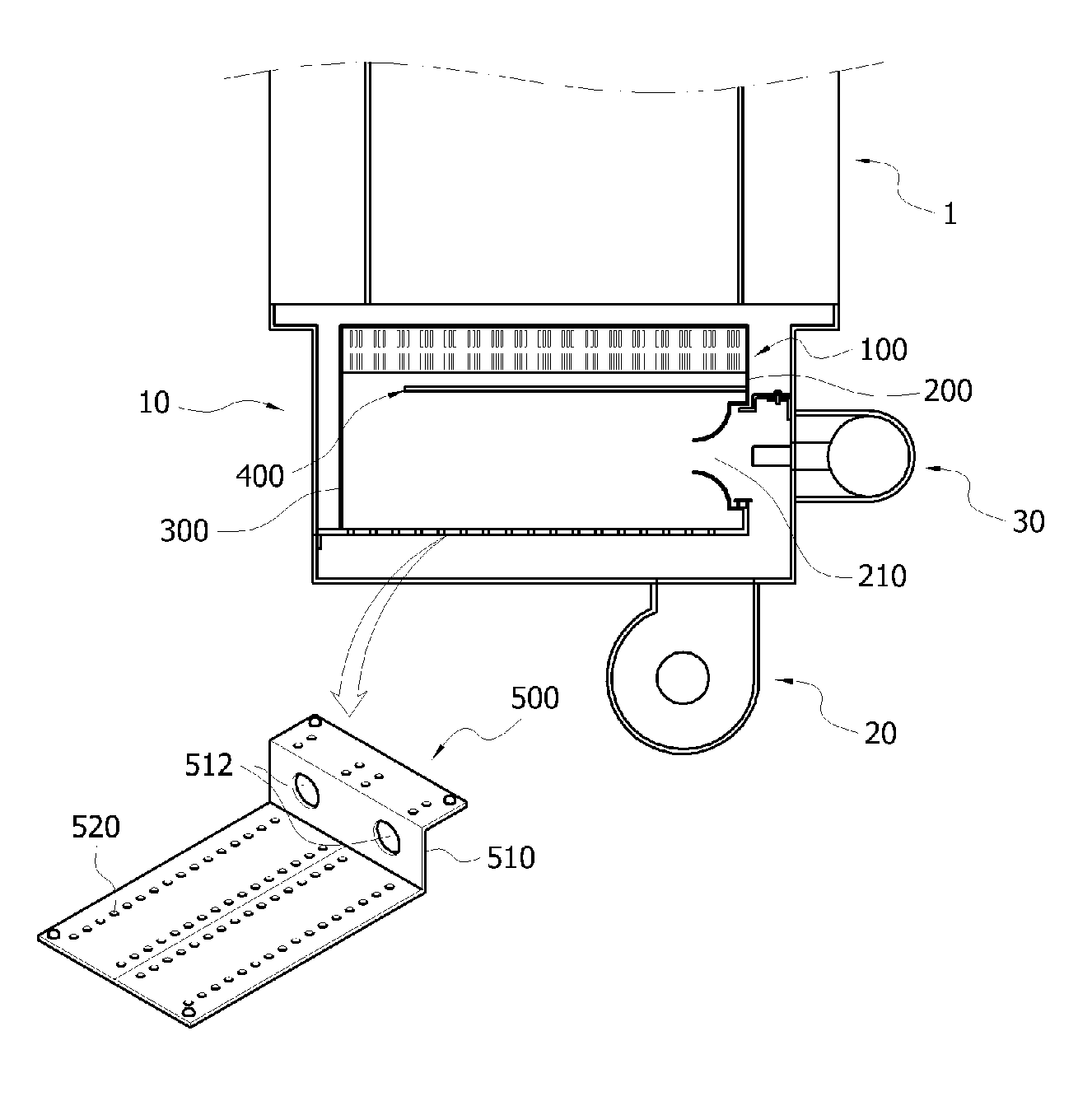

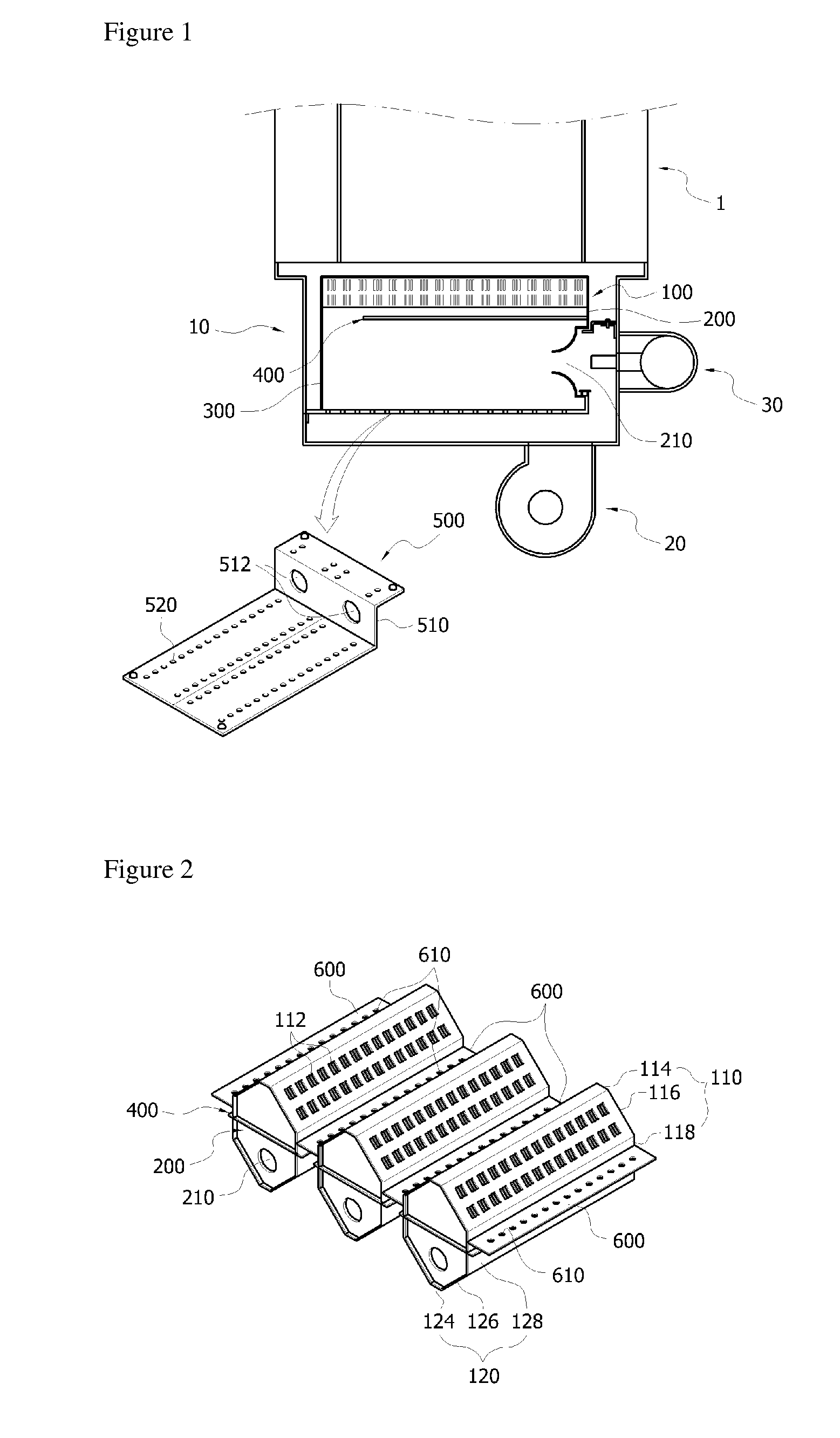

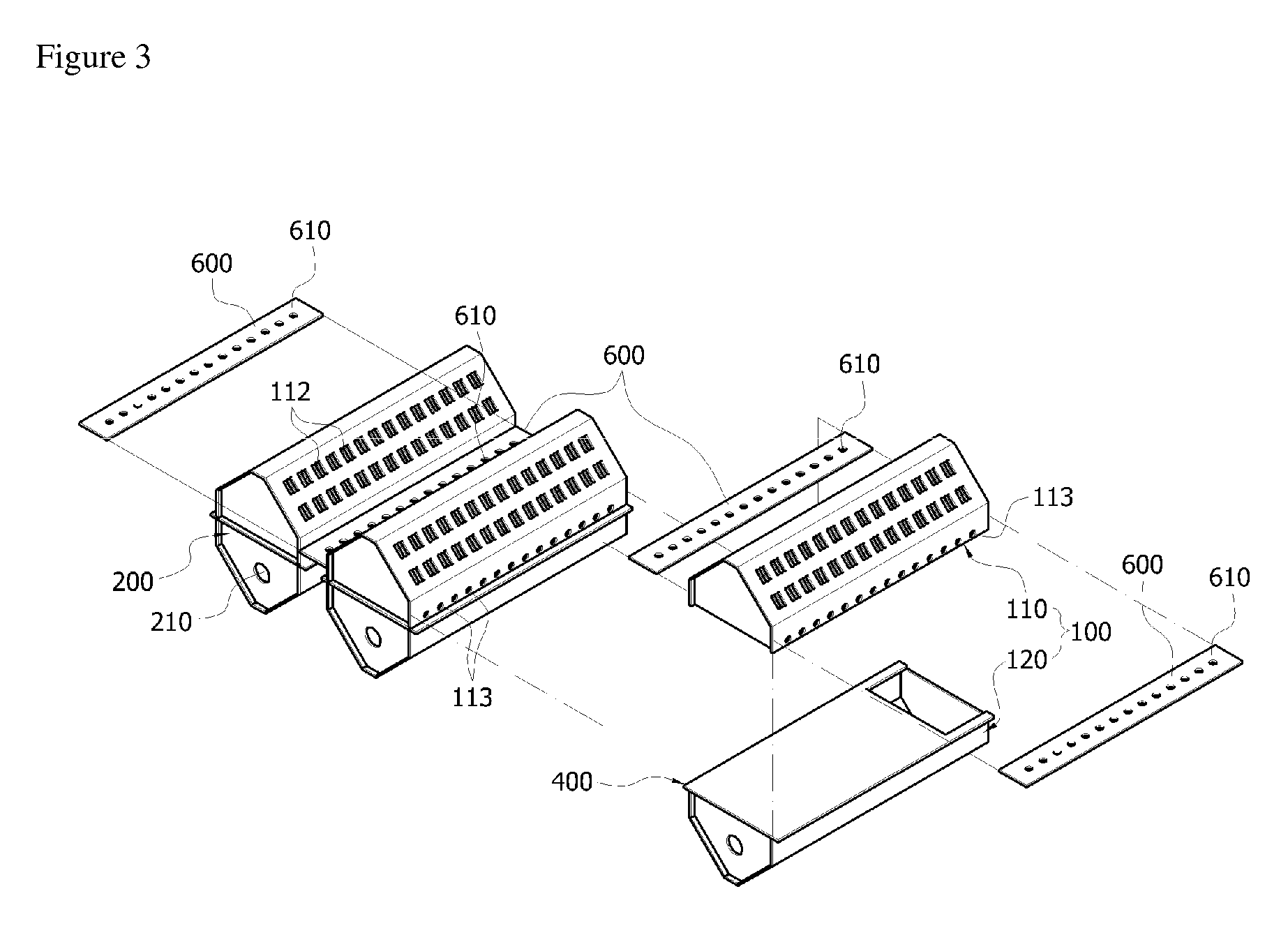

[0022]FIG. 1 is a cross-sectional side view of a burner according to the present invention. FIG. 2 is an assembled perspective view of burner bodies and connection plates according to the present invention. FIG. 3 is an exploded perspective view of the burner bodies and the connection plates shown in FIG. 2.

[0023]Referring to FIG. 1, the burner includes a casing unit 10 having an installation region formed therein, in which components of the burner are to be installed, a fan 20 which is connected and installed under the casing unit 10 so as to provide external air into the casing unit 10, a nozzle unit 30 which is connected and installed in one side of the casing unit 10 and has a leading end portion positioned inside the casing unit 10 so as to jet gas, and a burner body 100 which is installed inside the casing unit 10 so as to form flames.

[0024]A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com