Non-metallic material combustion performance testing apparatus

A technology of non-metallic materials and combustion performance, applied in the direction of measuring devices, analytical materials, material thermal analysis, etc., can solve the problems of increasing test costs, etc., and achieve the effects of reducing test costs, convenient operation procedures, and convenient adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments, but is not limited thereto.

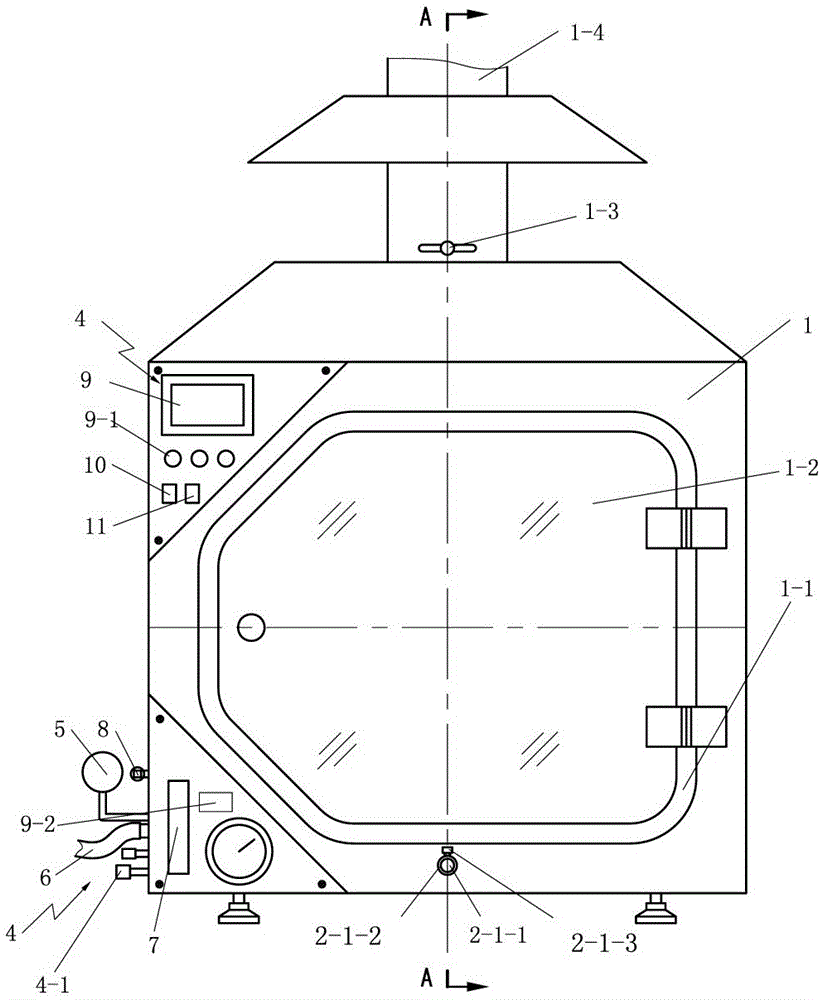

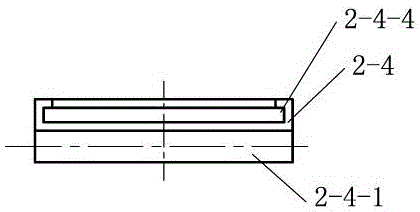

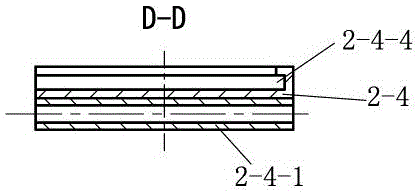

[0037] see Figure 1~5 As shown, a non-metallic material combustion performance testing device includes a combustion box body 1, a flame injection device 2, a sample fixing device 3 and a gas control mechanism 4, the combustion box body 1 is hinged with a door 1-1, and the top An air volume regulator 1-3 and a smoke exhaust port 1-4 are provided, and a base plate 1-5 is fixedly connected to the bottom, and the flame spraying device 2 and the sample fixing device 3 are installed and connected to the base plate 1-5 in the combustion box body 1 Above; The gas control mechanism 4 is installed on the side plate of the combustion box body 1, including the gas flow, pressure control part, gas switch, and timing control part. The flame spraying device 2 is connected to the gas flow and pressure control part respectively , It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com