Femtosecond laser-induced plasma method for increasing gaseous hydrocarbon fuel stability limit and device for realizing the method

A femtosecond laser and plasma technology, applied in the direction of using plasma, thrust reverser, machine/engine, etc., can solve the problems of easy extinguishment of flame, unstable combustion, etc., achieve high peak power, expand stability limit, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

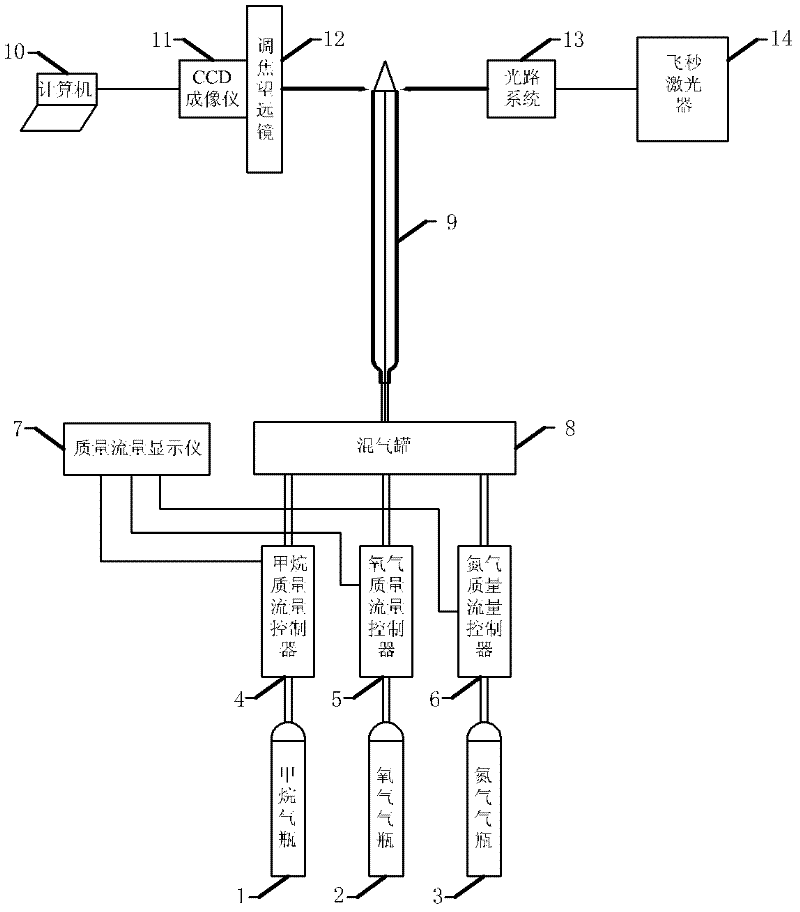

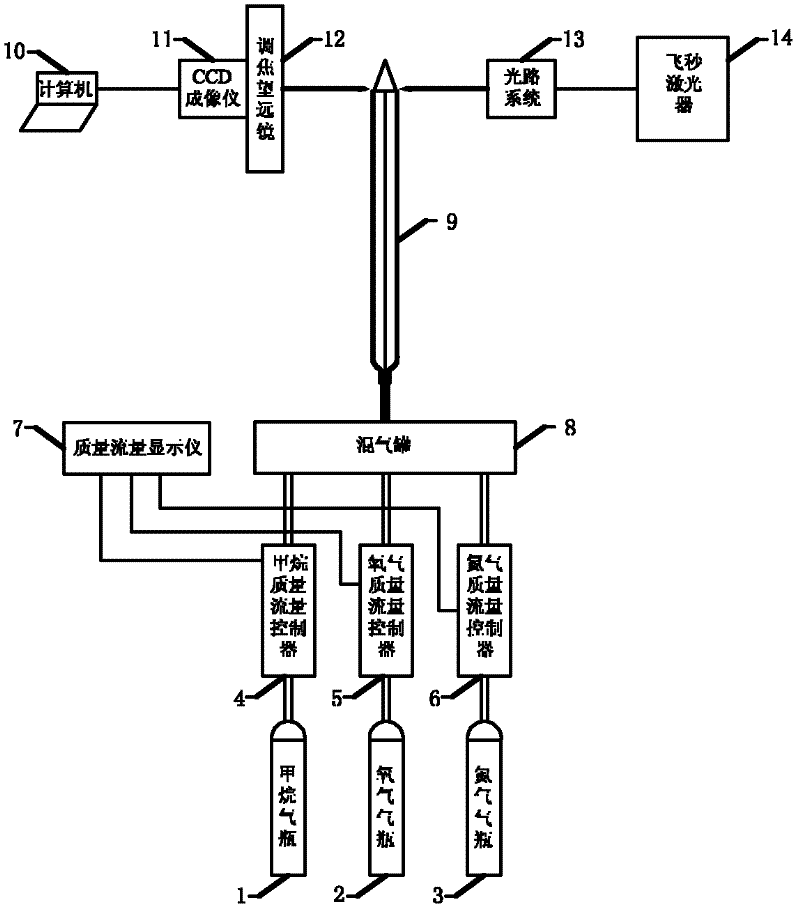

[0018] The specific embodiment one, femtosecond laser-induced plasma improves the method for gaseous hydrocarbon fuel stable burning limit, and it is realized by the following steps:

[0019] Step 1. Pass the mixed gas into the quartz glass circular tube, and ignite the mixed gas at the nozzle of the quartz glass circular tube to form a Bunsen burner flame, and make the speed of the mixed gas supercritical; the mixed gas It is a mixture of oxygen, nitrogen and combustible gases;

[0020] Step 2, using a femtosecond laser to emit a femtosecond laser beam, and focusing the femtosecond laser beam on the unburned area of the mixed gas described in step 1, inducing the mixed gas to generate plasma, so as to improve the flame stability limit.

specific Embodiment approach 2

[0021] Embodiment 2. The difference between this embodiment and the femtosecond laser-induced plasma method described in Embodiment 1 to improve the combustion stability limit of gaseous hydrocarbon fuels is that the combustible gases described in step 1 are methane, propane and acetylene one or a combination of several.

specific Embodiment approach 3

[0022] Embodiment 3. The difference between this embodiment and the femtosecond laser-induced plasma method described in Embodiment 1 to improve the combustion stability limit of gaseous hydrocarbon fuels is that the mixed gas described in step 1 is oxygen, nitrogen and methane The volume percentage of the methane ranges from 4.8% to 18.8%; the volume percentage of oxygen ranges from 16.9% to 21.8%; and the volume percentage of nitrogen ranges from 62.5% to 75.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com