Premixed pre-evaporation Bunsen burner combustion test device using aviation kerosene as fuel

A technology for aviation kerosene and combustion test, which is applied in the fields of energy and environment, and can solve the problems of inability to obtain laminar and turbulent flames at the same time, single flame structure, and uncontrollable flame shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

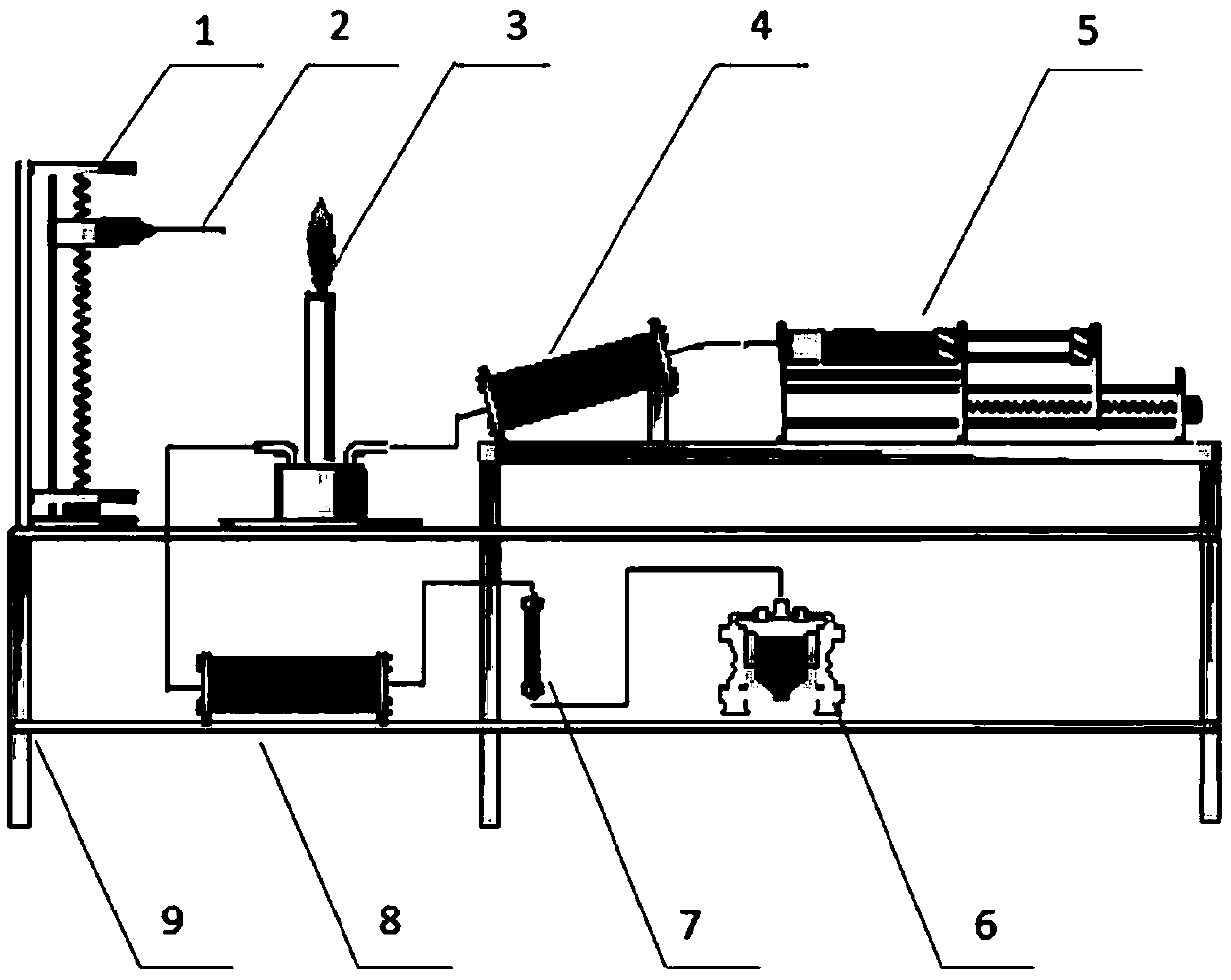

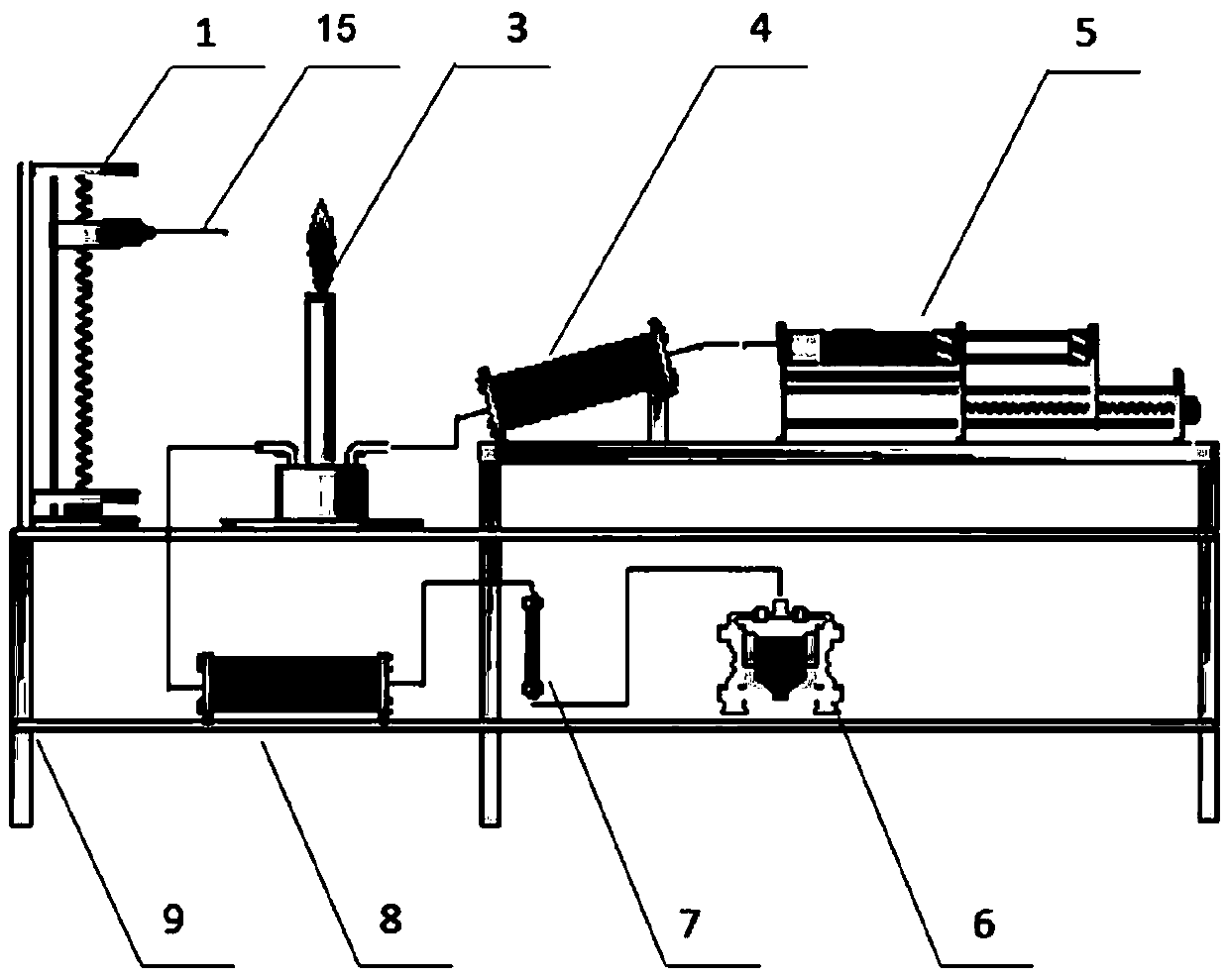

[0027] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a test device of the present invention, which includes a program-controlled coordinate frame 1, a thermocouple or a sampling tube 2, a Bunsen burner 3, a program-controlled fuel electric heater 4, a program-controlled fuel injection pump 5, an air pump 6, and a rotor flow rate Meter 7, program-controlled air heater 8, test support platform 9.

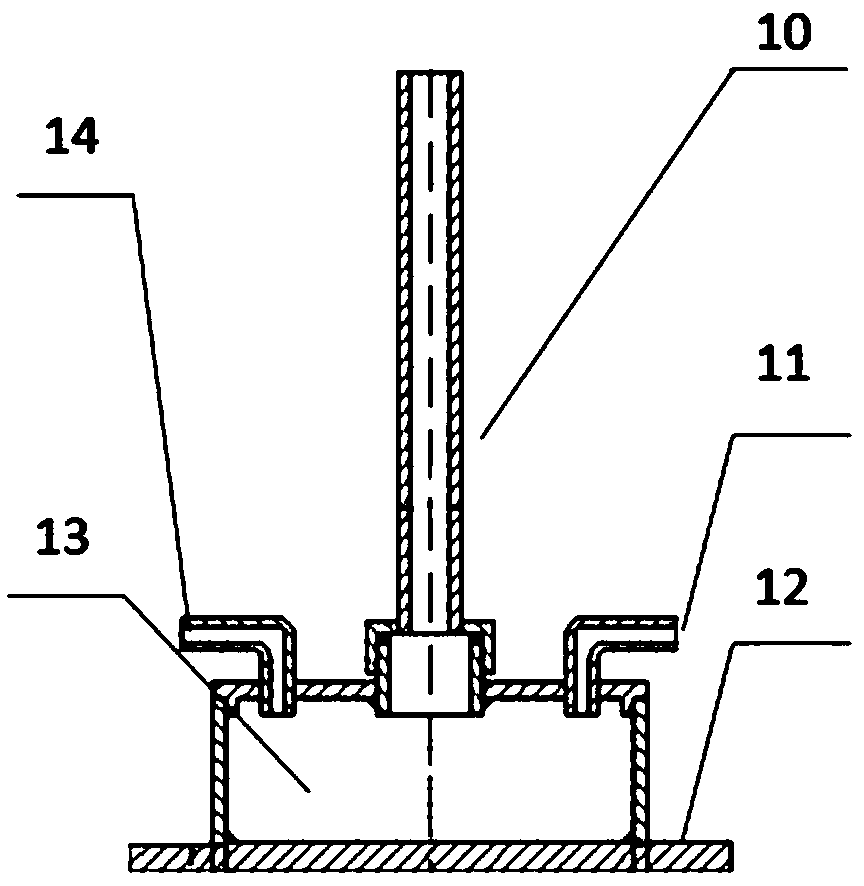

[0028] The test support platform 9 is divided into upper, middle and lower platforms. The middle platform of the test support platform 9 is provided with a Bunsen burner 3, and the Bunsen burner combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com