Composite element and use thereof

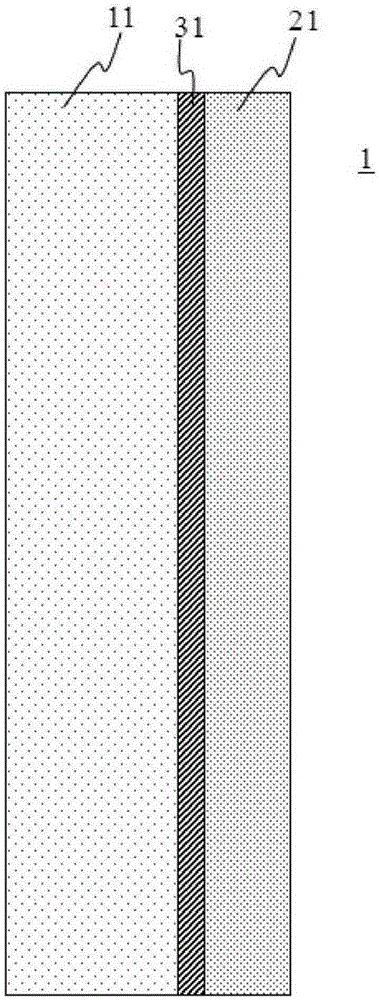

A technology of lightweight composite panels and polymer sheets, which is applied in applications, vehicle parts, and other household appliances, etc., and can solve the problems that composite panels do not meet fire protection requirements and do not have given dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 4

[0133] Weight per unit area: 2.78kg / m 2

[0134] Total thickness of organic layers: 50 μm

[0135] The ratio of the thickness of the glass layer to the total thickness of the organic layer: 1:0.045

example 5

[0138] Weight per unit area: 4.61kg / m 2

[0139] Total thickness of organic layers: 350 μm

[0140] The ratio of the thickness of the glass layer to the total thickness of the organic layer: 1:0.206

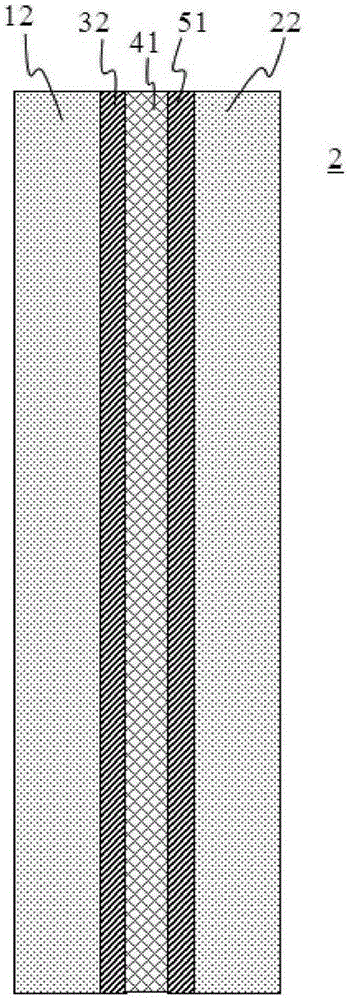

example 6

[0142]

[0143] Weight per unit area: 2.10kg / m 2

[0144] Total thickness of organic layers: 200 μm

[0145] The ratio of the thickness of the glass layer to the total thickness of the organic layer: 1:0.263

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com