A high-efficiency vertical hydrodynamic turbulent mill for superhard and ultrafine powder

An ultra-fine powder and super-hard technology, which is applied in grain processing and other directions, can solve the problems of reducing the fineness of crushing, cumbersome operation, and particle powder agglomeration, so as to reduce the dynamic load and static load, increase the collision probability, and strengthen the impact energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

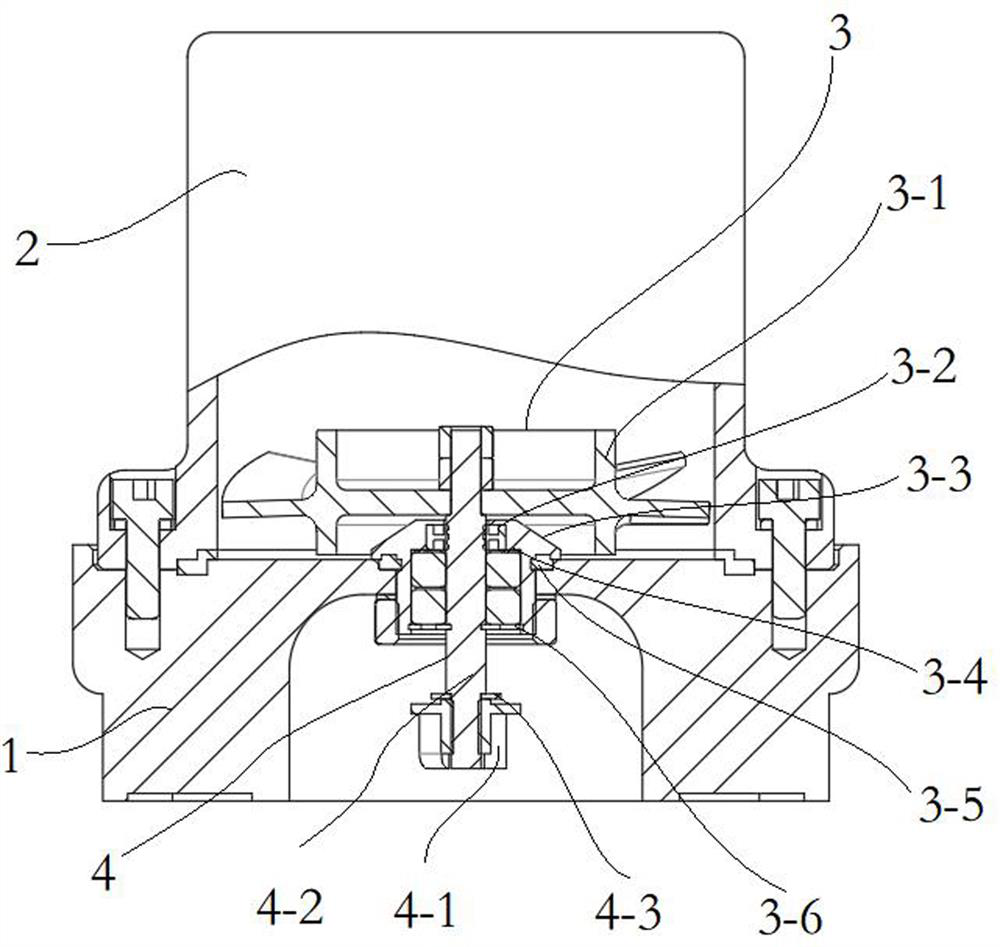

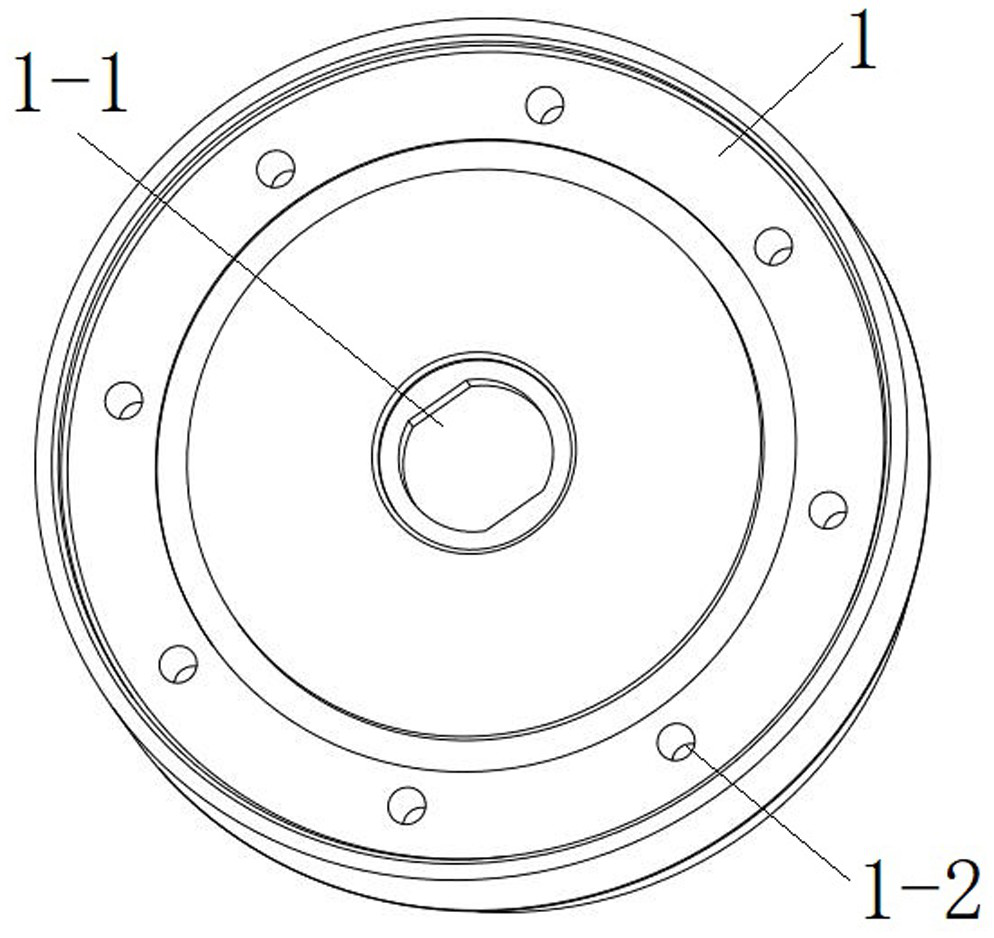

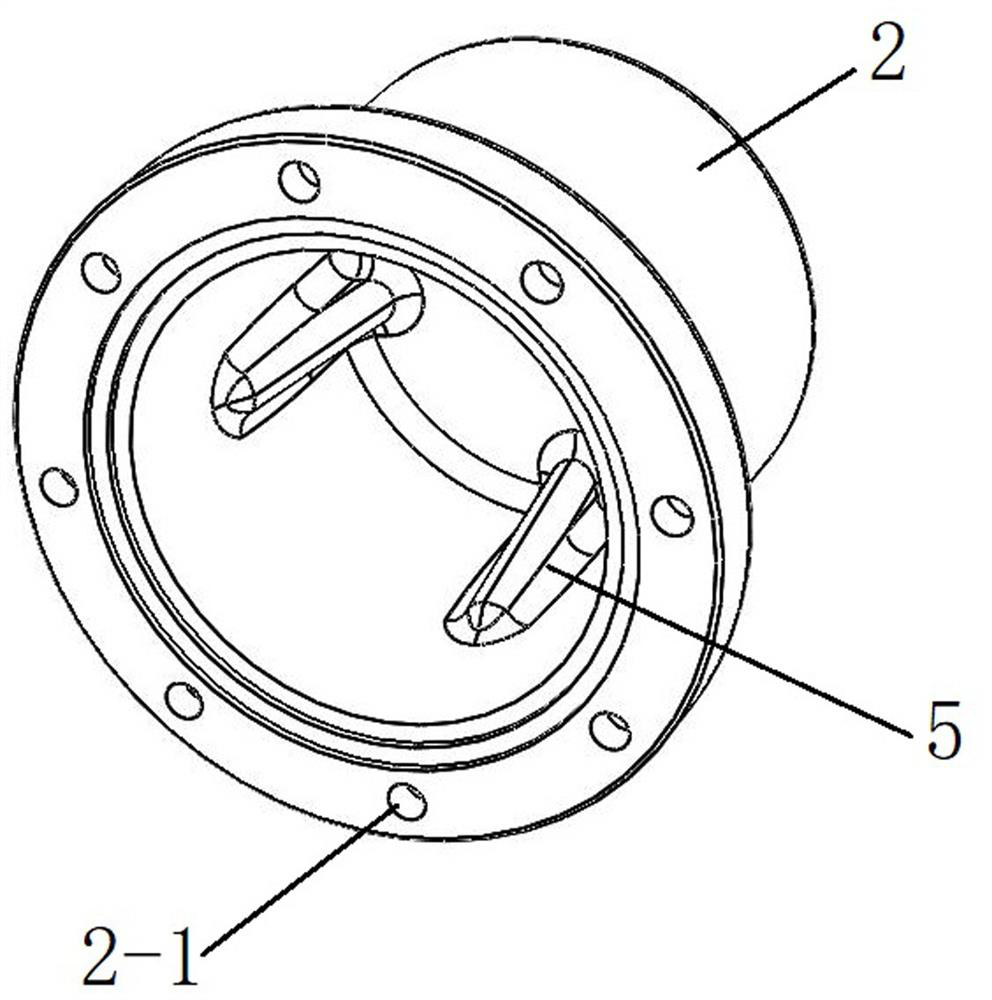

[0034] like Figures 1 to 3 As shown, a super-hard and ultra-fine powder vertical hydraulic turbulent mill of the present invention includes a mechanism base 1, a cover cylinder 2, a space curved turbine grinding mechanism 3 and a main shaft drive mechanism 4. The middle of the mechanism base 1 is provided with Mounting hole 1-1, and the bottom of the mechanism base 1 corresponding to the mounting hole 1-1 is provided with a spindle drive mechanism accommodating cavity, and the top of the mechanism base 1 around the mounting hole 1-1 is evenly distributed with 8 lower threaded holes 1-2. There are 8 upper threaded holes 2-1 on the outer edge of the bottom of the cylinder 2, the cover cylinder 2 is covered on the mechanism base 1, and a sealing washer is added between the cover cylinder 2 and the mechanism base 1, and the upper threaded holes 2- 1 is aligned with the lower threaded holes 1-2, and the upper and lower threaded holes are threaded through bolts. The cover cylinder ...

Embodiment 2

[0041] A super-hard and ultra-fine powder vertical hydraulic turbulent mill, the difference between this embodiment and Embodiment 1 is that the inner blades of the space curved turbine 3-1 and the axial disk are at an inclination angle of 30°; The inner wall is provided with four spoiler ribs 5, and the four spoiler ribs 5 are vertically and evenly distributed on the top of the inner wall of the cover cylinder 2 at an interval of 90° (such as Figure 7 shown).

[0042] The turbulent viscosity simulation test is carried out by using the superhard and ultrafine powder vertical hydraulic turbulent mill of the present embodiment, and the results are as follows: Figure 9 As shown, it can be seen that the turbulent viscosity in the center of the space curved turbine 3-1 is higher, and the two sides above the space curved turbine 3-1 are higher than the upper center, and the overall distribution of the turbulent viscosity inside the cover cylinder 2 is uneven. Turbulence is due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com