A high-power low-pulsation lobe rotor pump

A cam rotor pump, high-power technology, used in rotary piston pumps, rotary piston/oscillating piston pump components, pumps, etc., can solve the problem of reducing the service life of the unit, reducing the service life of shaft, bearing and seal, transmission The problem of large amplitude of axial radial excitation force can reduce vibration and noise, ensure stable operation, and reduce equipment quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

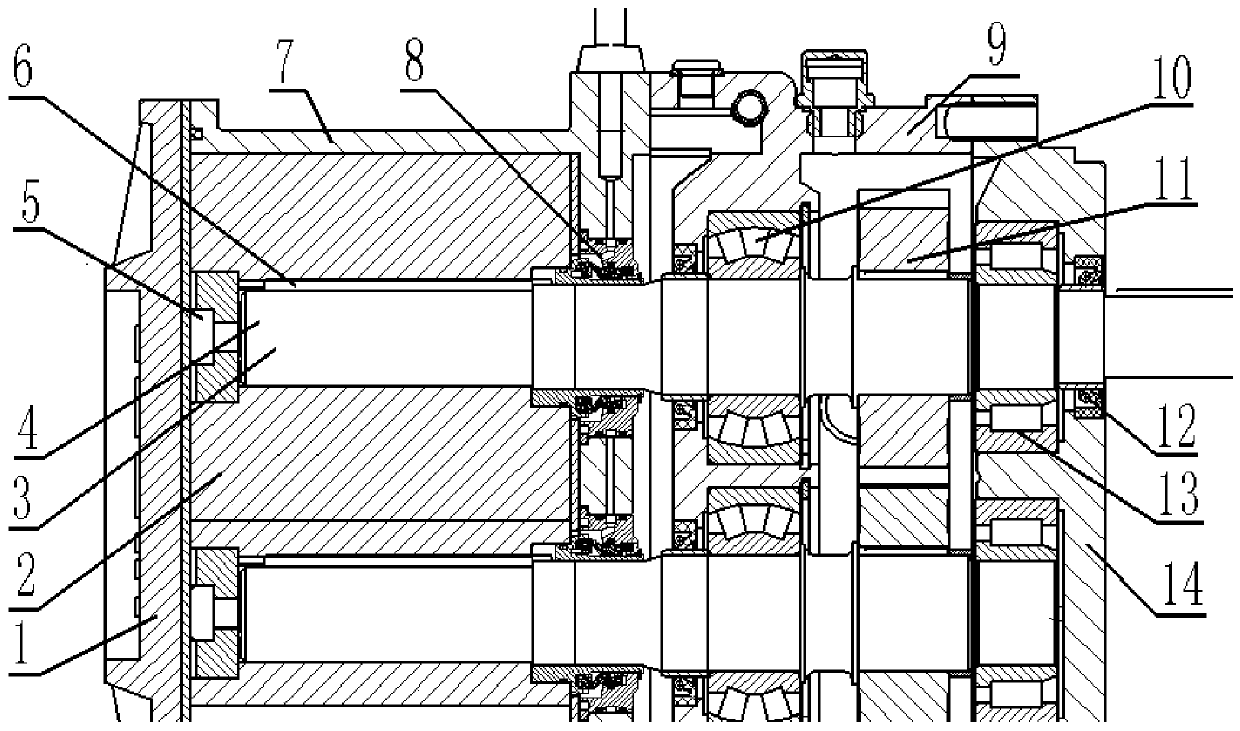

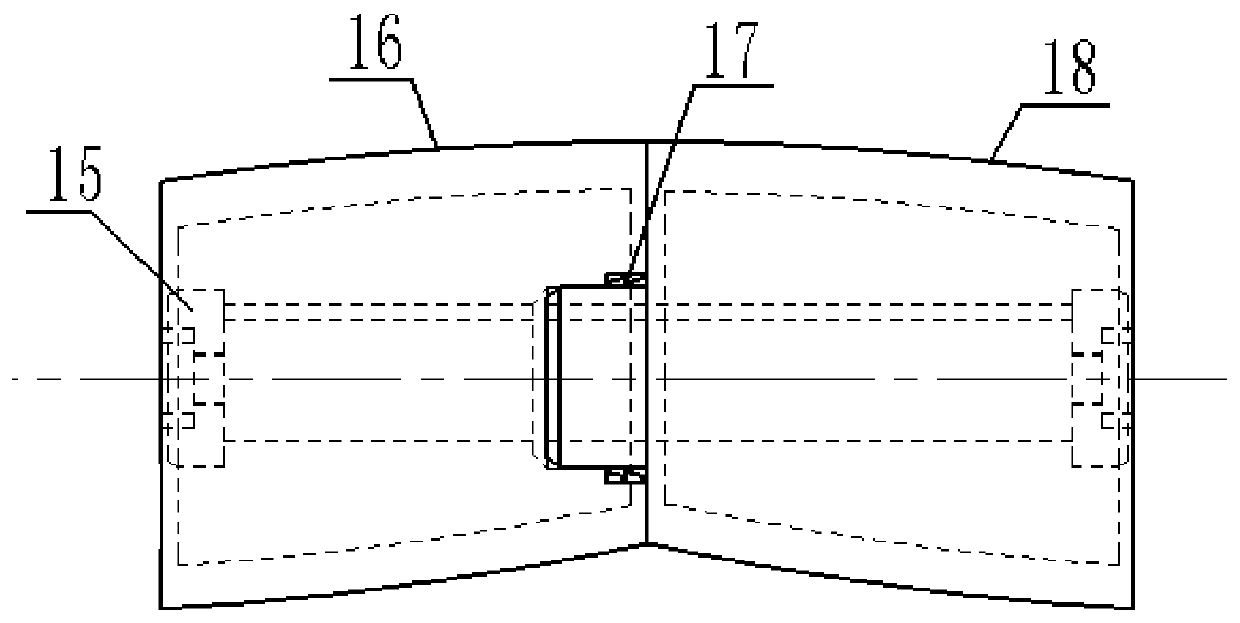

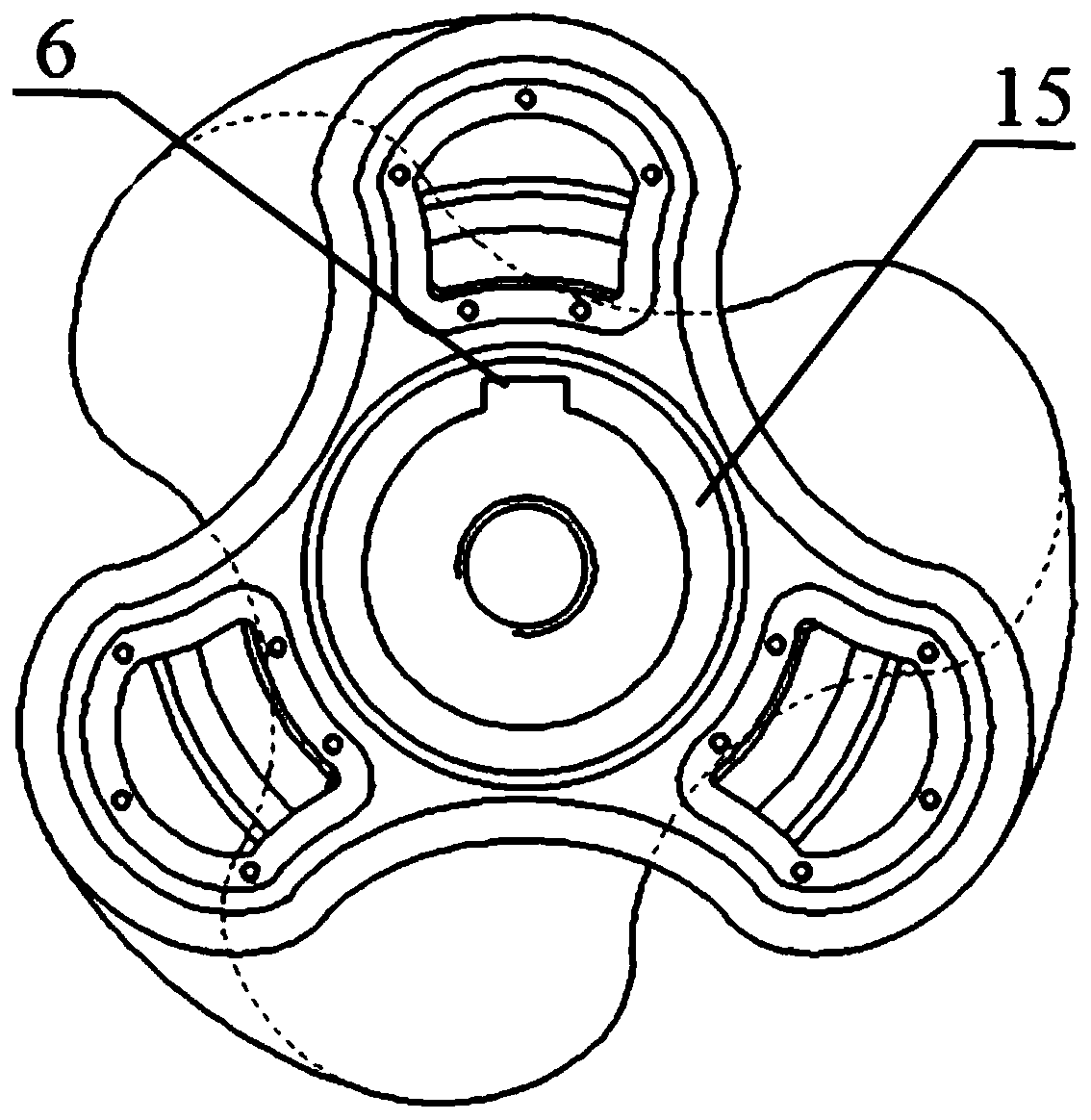

[0048] Specific embodiment: According to an example of a 1200 cubic large displacement rotor pump, the diameter of the rotor base circle is 450 mm, the software analysis shows that the mass of the solid rotor body of the pump is about 306.426 kg, and the mass of the rotor body with a hollow structure is 208.773 kg . From software analysis, it can be seen that the weight of the rotor as hollow is reduced compared with the original solid rotor: 306.426kg-208.773kg=97.653kg, and the weight is reduced by about 32%; r When =0.1mm, the radial force of the high-pressure end of the gradual gap rotor chamber to the rotor in the y direction is significantly lower than that of the equal-gap rotor. The maximum radial force is 6.7kN, which is less than that of the equal-gap rotor. It is 12% smaller, and the radial force in the x direction of the gradual clearance rotor cavity is 4.4kN, which is 19% smaller than that of the equal clearance rotor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com