Liquid Bunsen burner

A Bunsen burner and liquid technology, which is applied in the direction of combustion method, combustion type, burner, etc., can solve the problems of flame stability pulsation, inability to obtain stable laminar flame, etc., to save test funds, improve atomization effect, The effect of evaporation stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

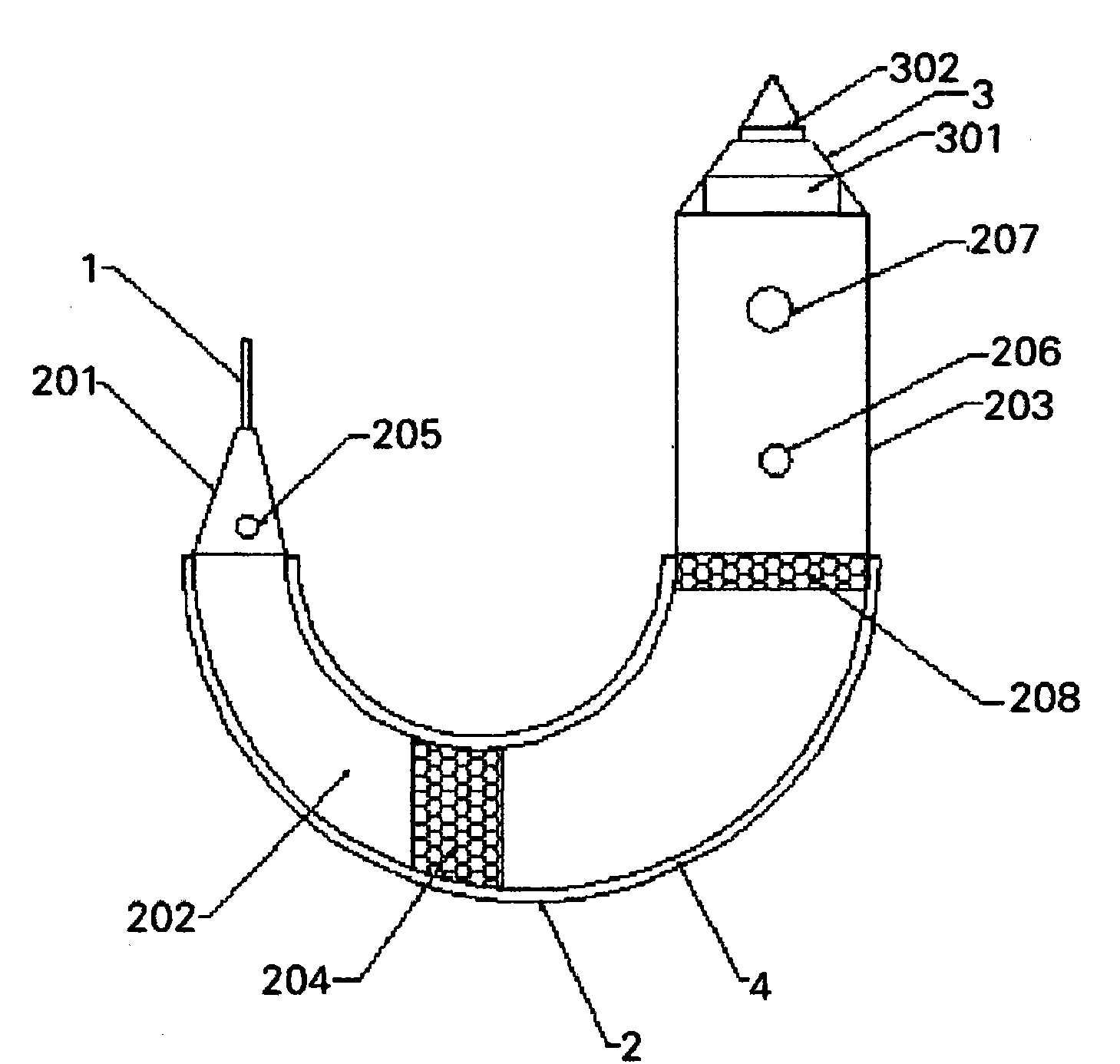

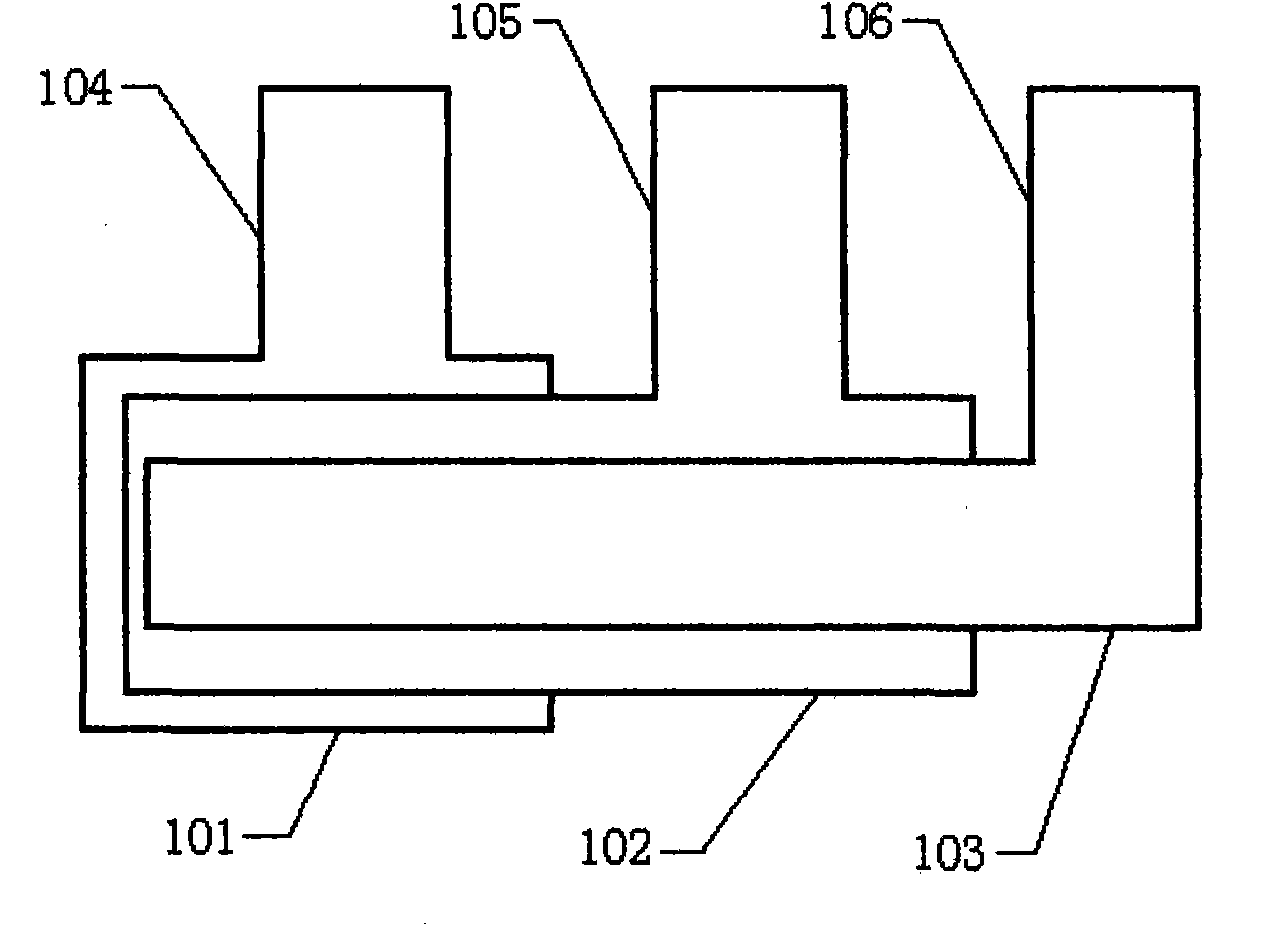

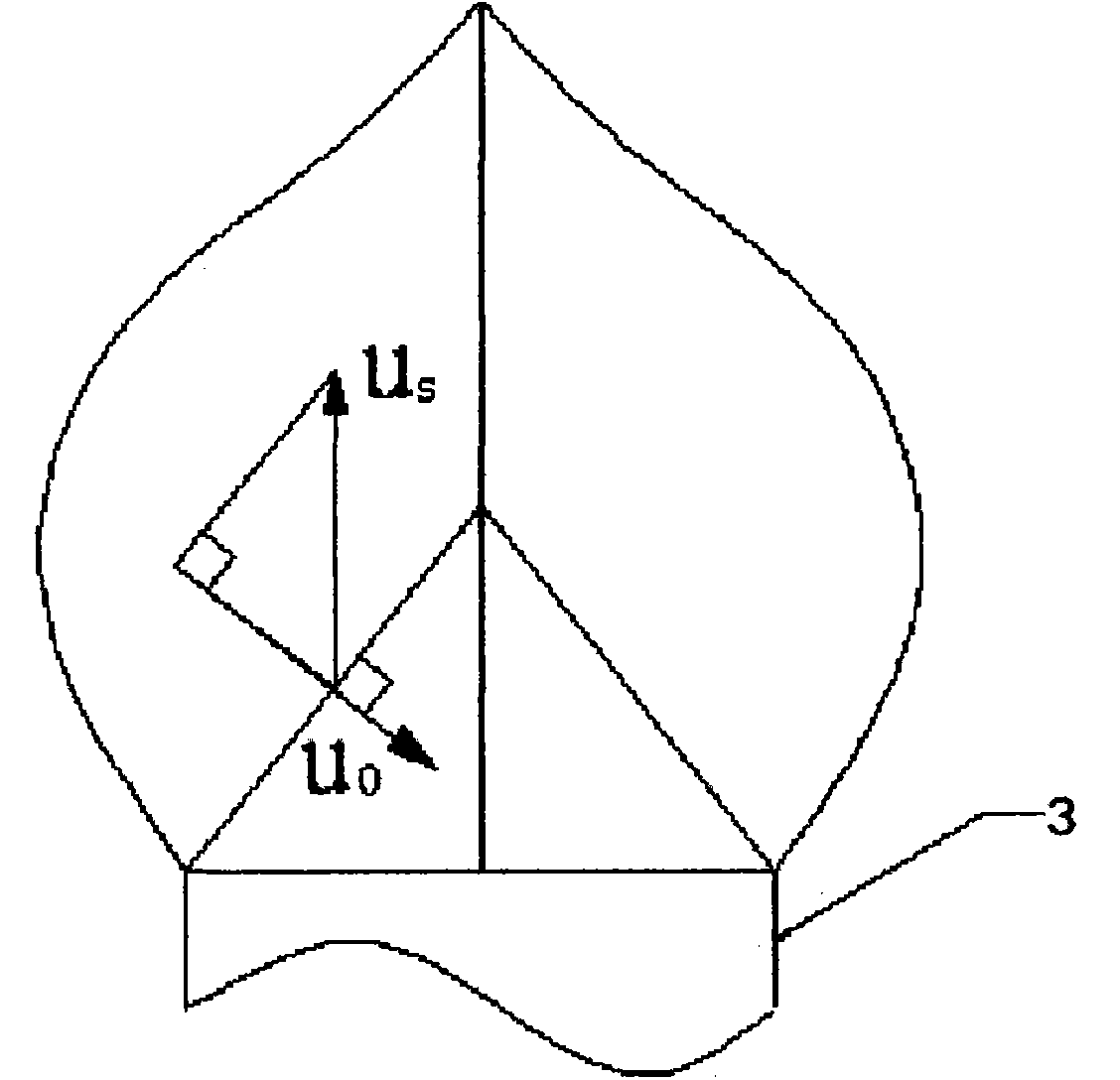

[0034] figure 1 is a schematic diagram of a liquid Bunsen burner according to an embodiment of the present invention. A liquid Bunsen burner generally includes a nozzle 1 , a lamp tube 2 and a lamp cap 3 connected in sequence. The nozzle 1 includes an inner air pipe 103 installed coaxially and located in the inner ring, which can be used for ventilation of air or combustion-supporting gas. The liquid pipe 102 located in the middle ring can be used for spraying liquid, and the outer air pipe 101 located in the outer ring can be used for spraying air or combustion-supporting gas. The outer air pipe 101, the liquid pipe 102 and the inner air pipe 103 form a concentric three-ring nested structure, and there is a certain gap between each pipe to ensure the circulation of corresponding gas and liquid. The lamp tube 2 may be a U-shaped tube, which includes an atomizing expansion tube 201 , an evaporative expansion tube 202 and a mixing tube 203 connected in sequence. The atomizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com