Multi-stage free-style gas atomization spray disc with gas self-circulation function

A self-circulation and gas atomization technology, applied in the field of powder metallurgy, can solve the problems of increasing production cost, increasing gas consumption, increasing the burden on the rear fan of the atomizing system, and achieving the effect of gas balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

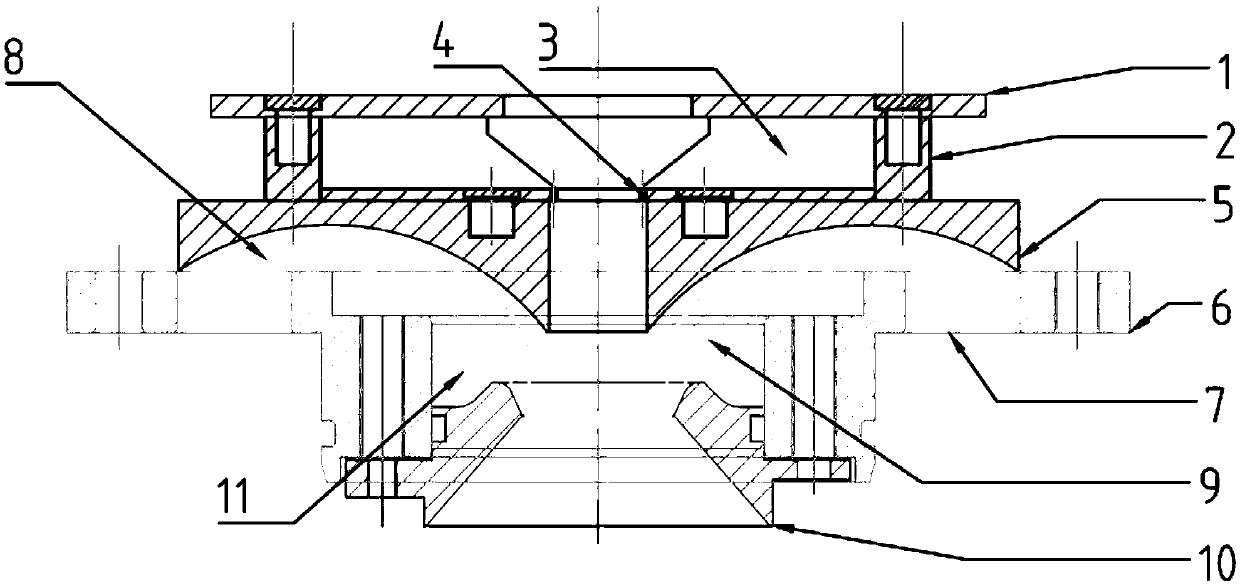

[0037] A multi-stage free-style gas atomization spray disc with gas self-circulation function, such as figure 1 As shown, it includes the auxiliary nozzle, the main nozzle and the circulating gas guide 5, the middle of the auxiliary nozzle is the melt channel, the surrounding of the auxiliary nozzle is the auxiliary nozzle air chamber 3, the middle of the circulating gas guide 5 is the melt channel, and the main The middle of the nozzle is a melt channel, the main nozzle is surrounded by the main nozzle air chamber 11, the auxiliary nozzle is connected to the upper end of the circulating gas guide 5, the lower end of the circulating gas guide 5 is connected to the main nozzle, the melt channel of the auxiliary nozzle, the circulation The melt channel of the gas guide 5 and the melt channel of the main nozzle are connected up and down, and a circulation guide channel 8 is formed between the circulating gas guide 5 and the main nozzle, and the circulation guide channel 8 is conne...

Embodiment 2

[0051] The multi-stage free-style gas atomization spray disc in Example 1 was used for gas atomization.

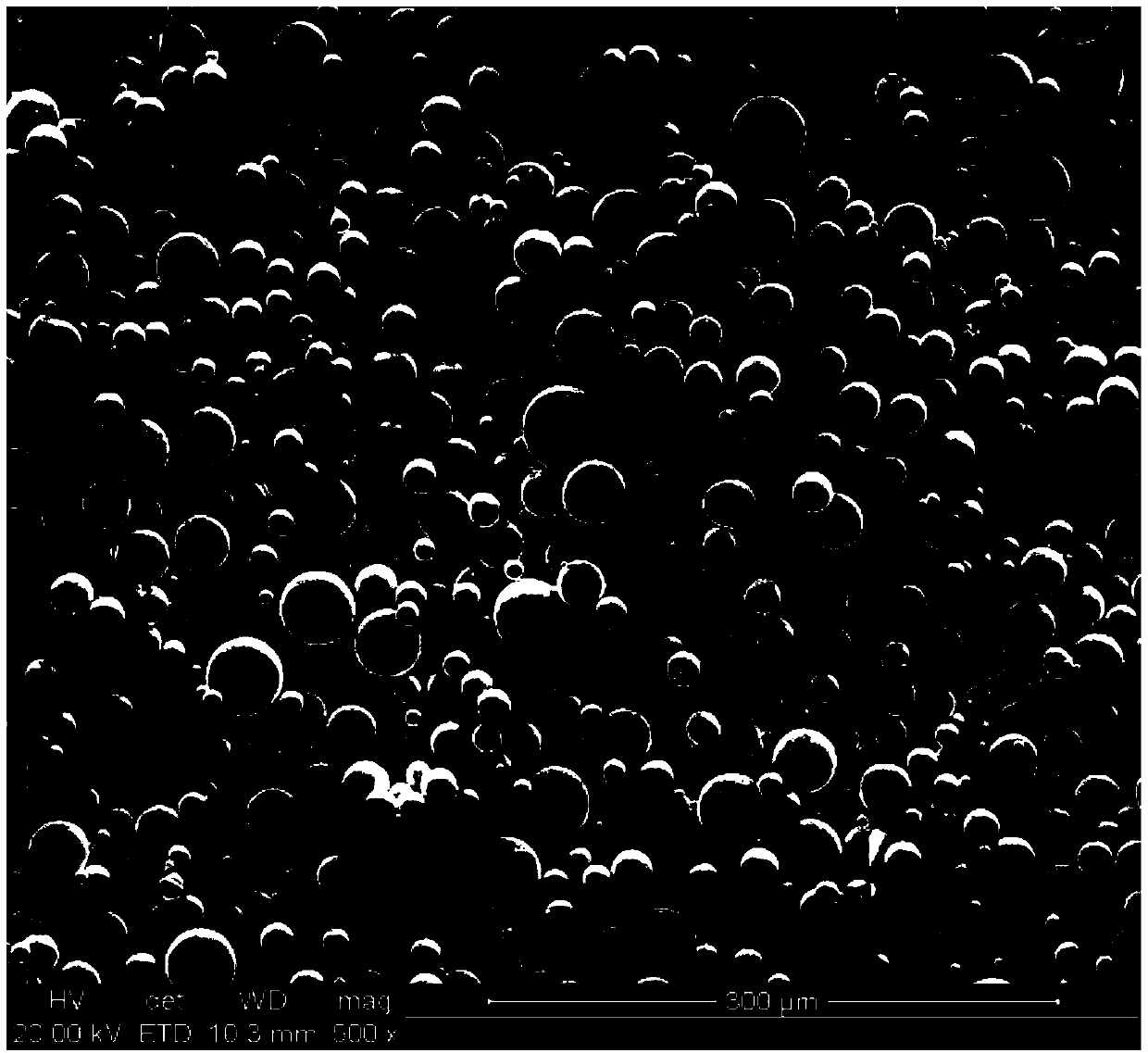

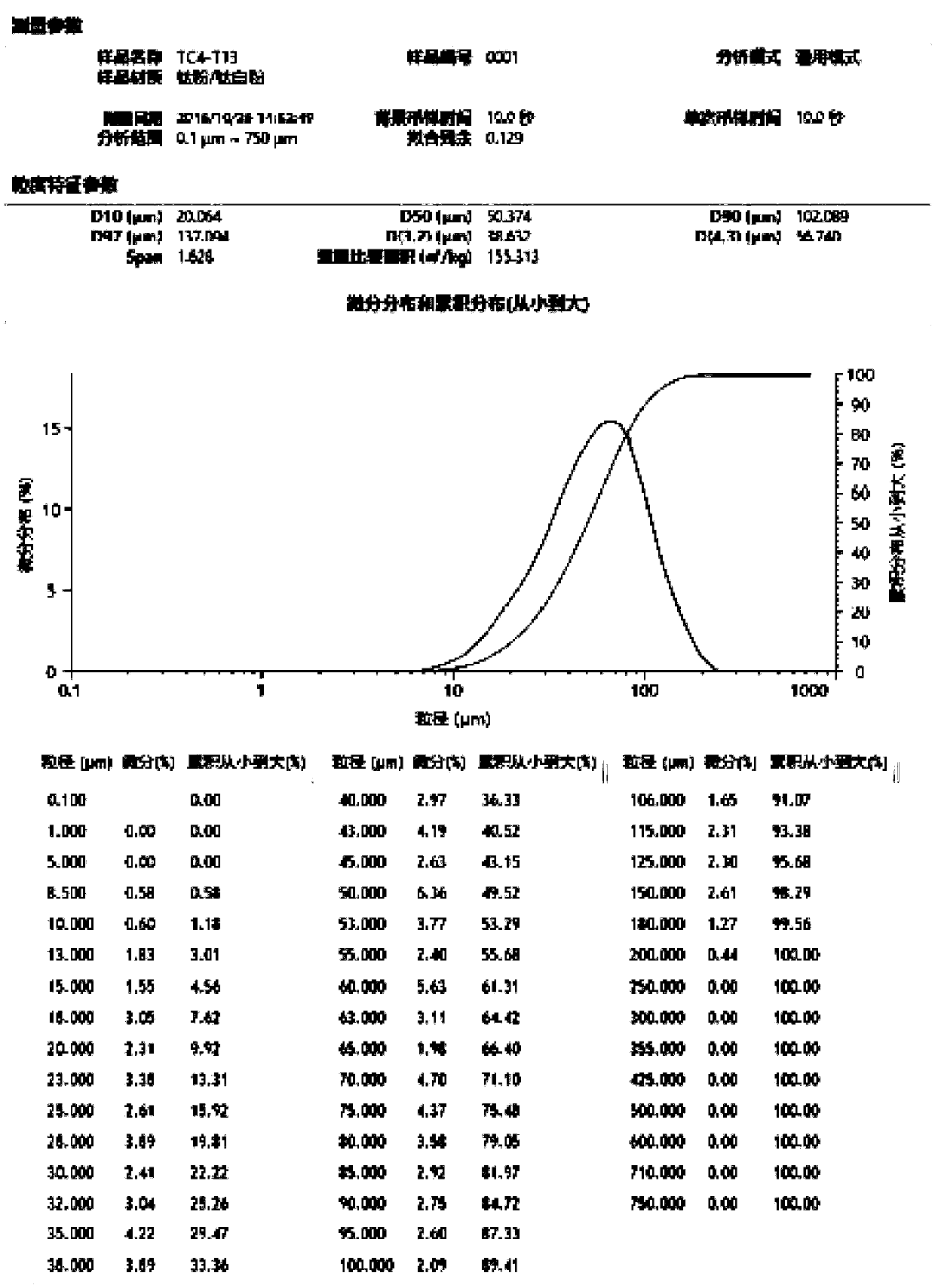

[0052] Use the nozzle of the present invention on the smelting equipment without crucible induction electrode to prepare TC4 titanium alloy powder. The diameter range of the raw material rod used is 40-50 mm, and the mass median particle diameter of the prepared powder is D 50 For: 45μm≤D 50 ≤70μm. The atomizing gas pressure of the auxiliary nozzle is 0.38MPa, the atomizing air pressure of the main nozzle is 3.8MPa, and no splash occurs during the atomization process. Typical characteristics of its powder see figure 2 , its powder particle size test report see image 3 .

Embodiment 3

[0054] The difference from Example 2 is that the atomizing gas pressure of the auxiliary nozzle is adjusted to 0.4MPa, and the atomizing pressure of the main nozzle is 4.0MPa. At this time, the particle size of the metal powder prepared is D 50 45.5μm, particle size report see Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com