Device and method for testing combustion performance of rubber hose for conveying liquefied petroleum gas

A technology of liquefied petroleum gas and rubber hose, which is applied in the direction of chemical analysis by means of combustion, which can solve problems such as the inability to meet the requirements of rubber hose combustion tests, and achieve the effects of high accuracy, accurate testing, and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

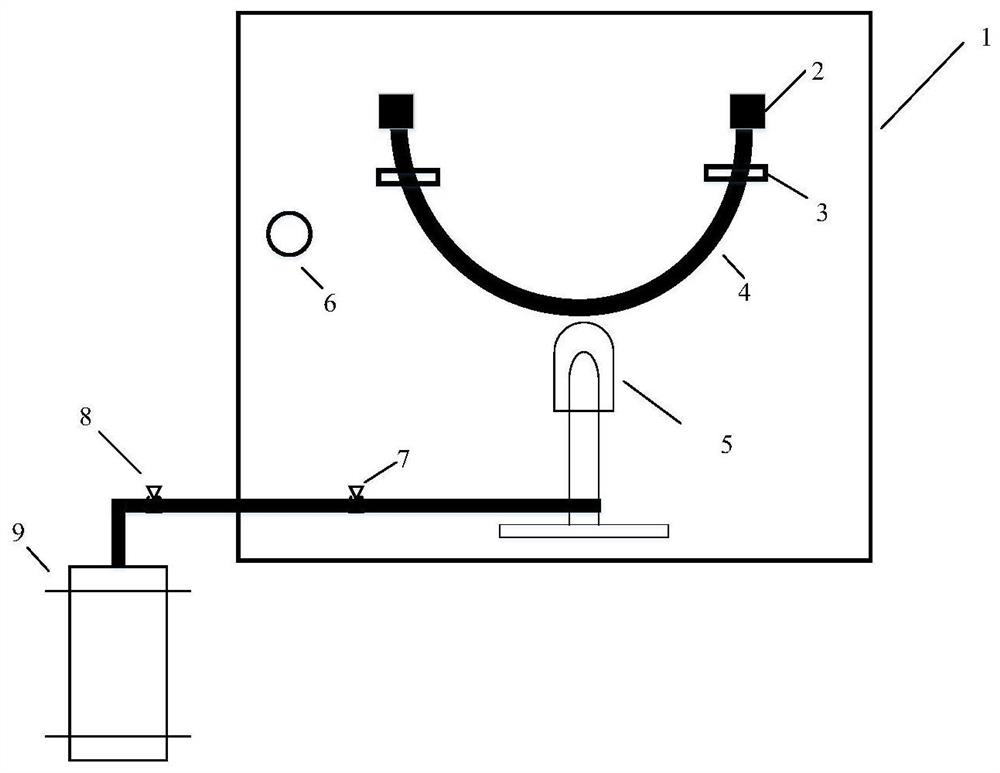

[0034] Such as figure 1 As shown, the main body of the rubber hose combustion performance testing device for liquefied petroleum gas transportation of the present invention is a box structure (i.e. reaction box 1), and the reaction box 1 is provided with hose fixing tool 3, Bunsen burner 5 and fuel line. The hose fixing tool 3 is used to fix the rubber hose 4 to be tested and make the rubber hose 4 bend. The rubber hose 4 is filled with liquefied petroleum gas, and the two ends of the rubber hose are blocked with caps 2 . The Bunsen burner 5 is located directly below the curved rubber hose. In order to meet the standard requirements for flame coverage, the inner diameter of the flame mouth of the Bunsen burner 5 is controlled to be 10mm. The fuel pipeline is used for the fuel supply of the Bunsen burner 5, and the fuel pipeline is provided with a pressure regulating valve 7. The fixed tooling set in the reaction box can effectively fix the rubber hose to be tested and keep ...

Embodiment 2

[0036] On the basis of embodiment 1, further as figure 1As shown, the present invention can also be extended to the scheme of embodiment 2. That is: the main body of the rubber hose combustion performance testing device for liquefied petroleum gas transportation of the present invention is a box structure (i.e. reaction box 1), and the reaction box 1 is provided with hose fixing tool 3, Bunsen burner 5 and fuel pipeline. The hose fixing tool 3 is used to fix the rubber hose 4 to be tested and make the rubber hose 4 curved. Preferably, but not limited to, the rubber hose 4 can be bent into a U shape, and the bending radius can be set to 10-15 times the outer diameter. Preferably but not limitatively, the hose fixing tool 3 can include a hose clamp structure, and the hose clamp can move up and down along the corresponding guide rails (not shown in the figure), so as to ensure that the rubber hose 4 to be tested is consistent with the Bunsen The distance of the outer flame of ...

Embodiment 3

[0039] Embodiment 3 The test method for the combustion performance of the rubber hose used for the transportation of liquefied petroleum gas, in addition to using the test device in the aforementioned device embodiment, also includes the following steps:

[0040] Step 301, bend the rubber hose 4 to be tested filled with liquefied petroleum gas into a U shape and fix it in the reaction box 1 through the hose fixing tool, and seal the two ends of the rubber hose with caps 2 . Specifically, one end of the rubber hose 4 can be sealed with the cover 2, and civil power diesel (straight-chain alkane) is injected into the rubber hose 4 (rubber material conforming to the ISO1817 standard) from the other end, and the diesel oil is completely filled with the rubber hose 4 to be tested. Utilize capping cap 2 after pipe 4 to block the other end of rubber hose.

[0041] Step 302, fix the two ends of the rubber hose 4 to be tested on the hose fixing tool 3 respectively, and bend them into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com