Combustion-supporting method by activating oxygen molecules by using laser

An oxygen molecule and laser technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of low combustion efficiency and unstable fuel combustion, achieve stable combustion performance, reduce ignition temperature, and accelerate reaction. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

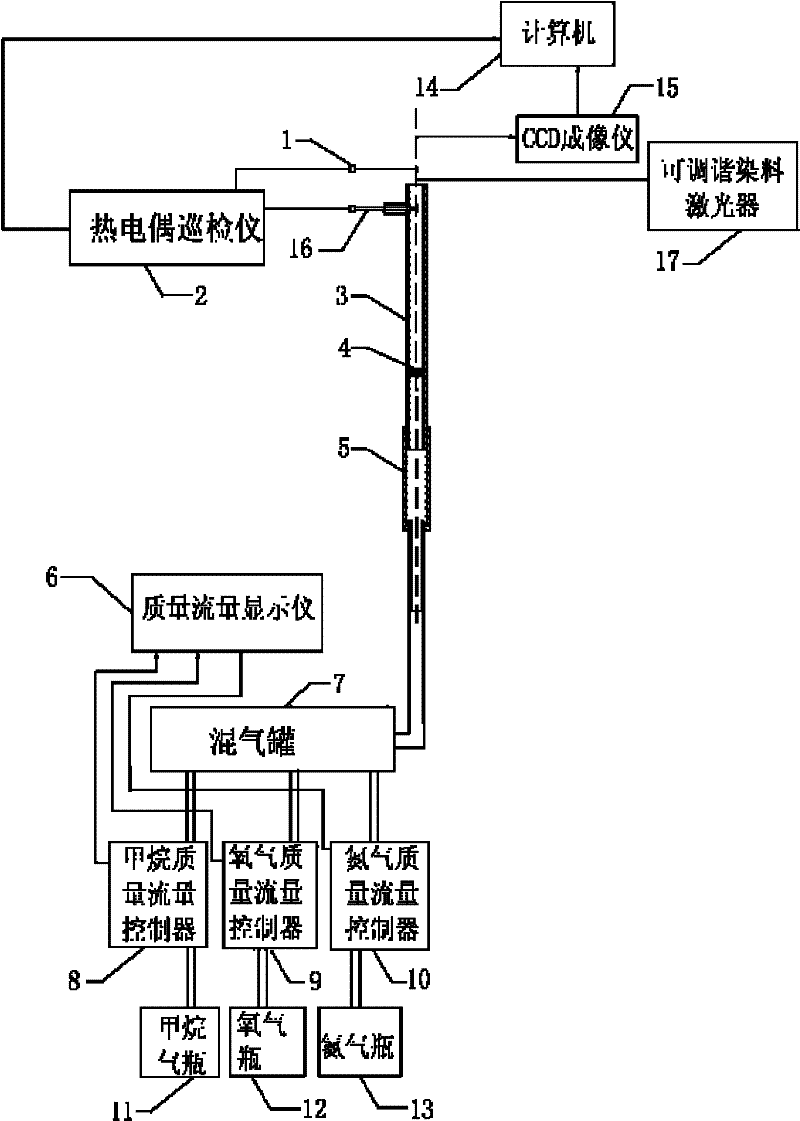

[0009] Step 1: Pass the mixed gas into the quartz circular tube 3, and ignite the mixed gas at the outlet of the quartz circular tube 3 to generate a Bunsen burner flame; the mixed gas is a mixture of oxygen and other combustible gases;

[0010] Step 2: Use the tunable dye laser 17 to emit a laser beam to the gas unburned area under the Bunsen burner flame mentioned in Step 1 to realize laser combustion.

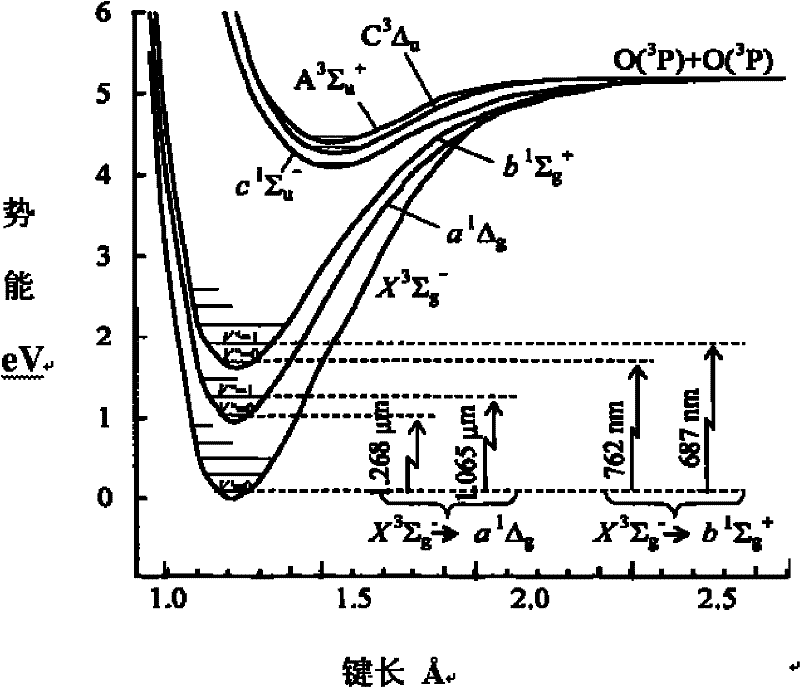

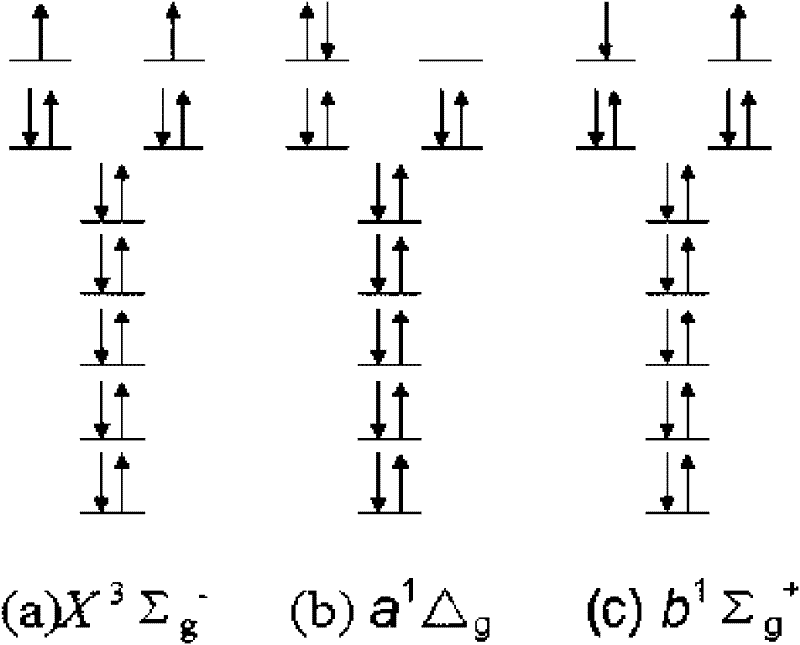

[0011] This embodiment adopts the principle of laser activation of oxygen molecules to support combustion, combined with figure 2 and image 3 In this embodiment, the use of laser to activate oxygen molecules to support combustion is to use laser to excite the ground state oxygen molecules to an excited state to increase the activity of the reactants, thereby increasing the rate of the chain reaction and branched chain reaction that trigger the combustion of the mixed gas, and accelerate the combustion. . Table 1 shows the transitions corresponding to the excited state ox...

specific Embodiment approach 2

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or Embodiment 2 is that the single pulse energy output by the tunable dye laser 17 ranges from 1 to 100 mJ.

specific Embodiment approach 3

[0022] Embodiment 4: The difference between this embodiment and Embodiment 1 or 2 is that the single pulse energy output by the tunable dye laser 17 ranges from 7 to 10 mJ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com