Bunsen burner with tapered flame burned and flame propagation speed measuring method

A measurement method, Bunsen burner technology, applied in the direction of combustion method, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problem of inaccurate measurement of flame propagation speed, etc., achieves improved and enhanced steady flow effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

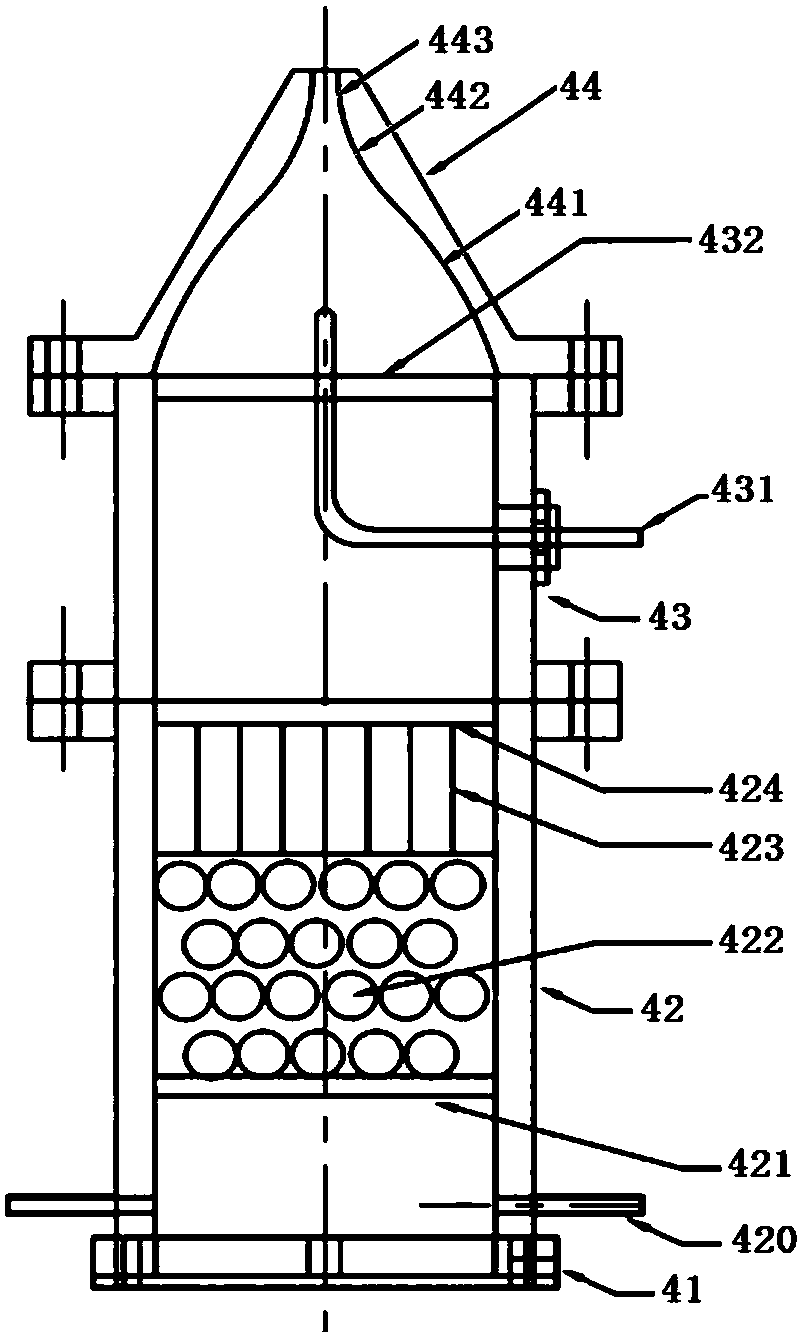

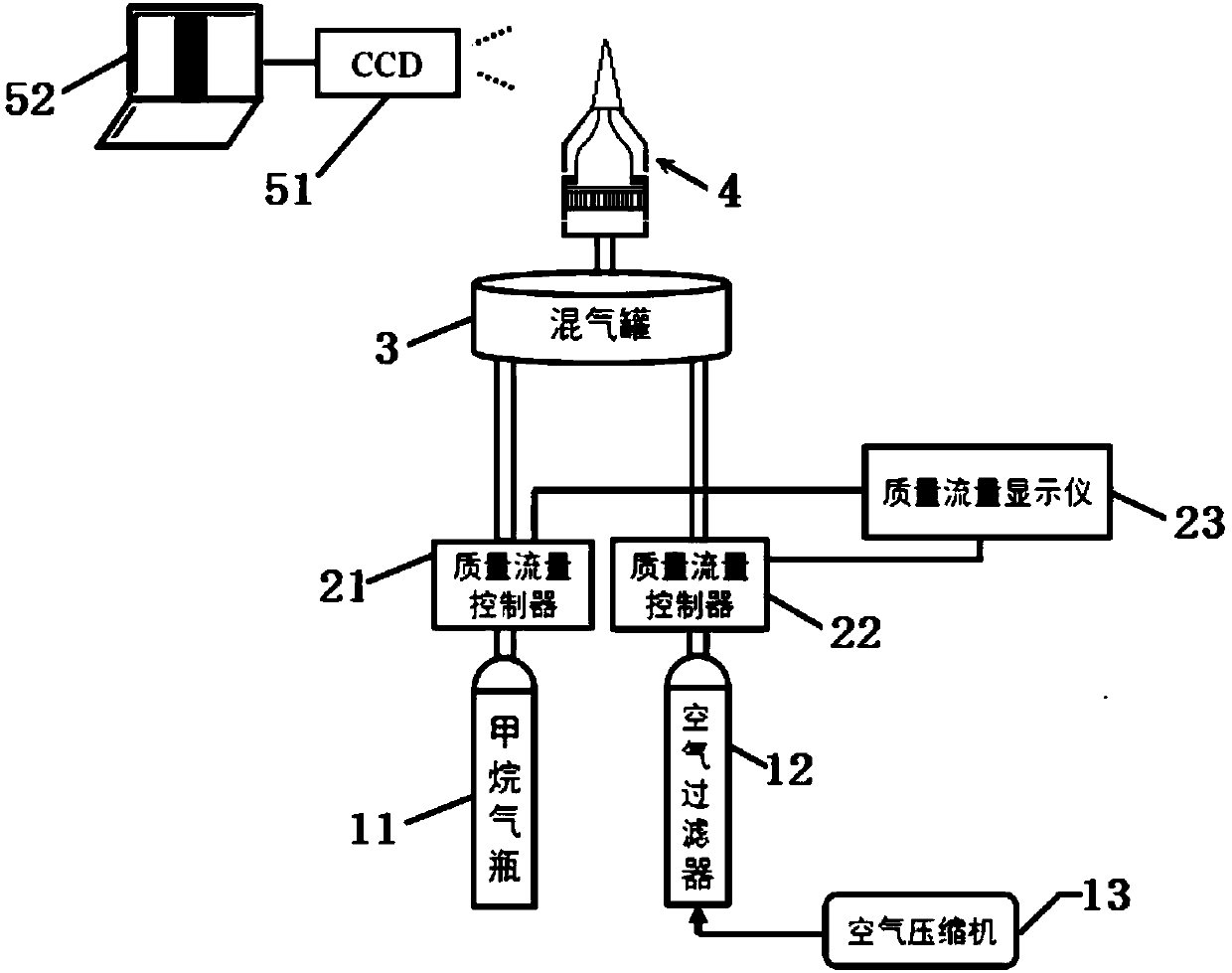

[0052] combine figure 1 , a burning conical flame Bunsen burner of the present invention includes a Bunsen burner body 4, and the Bunsen burner body 4 is mainly composed of a lamp body segment and a lamp nozzle 44 connected together. The lamp body section includes an outer casing and an inner cavity for mixed flow channeling of the gas, and the lamp nozzle 44 is used for ejecting the gas to form a flame.

[0053] The inner cavity of the lamp body section is provided with a filler layer 422, a flow equalizer 423 and a first sintered mesh 432 from bottom to top, and the filler layer 422 and the flow equalizer 423 are located on the upper side of the third sintered mesh 421 below the second sintered mesh 424 In between, that is, the third sintered mesh 421 is used to carry the filler layer 422, and the second sintered mesh 424 is used to cover it.

[0054] A base 41 is connected to the bottom of the lamp body section, and a gap space is formed between the base 41 and the third s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com