A flotation machine for flotation of coarse-grained materials

A flotation machine and coarse-grained technology, which is applied in the field of flotation machines, can solve the problems of small stirring force, easy to press the flotation cell, poor sorting effect of coarse-grained materials, etc. The effect of the chance of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

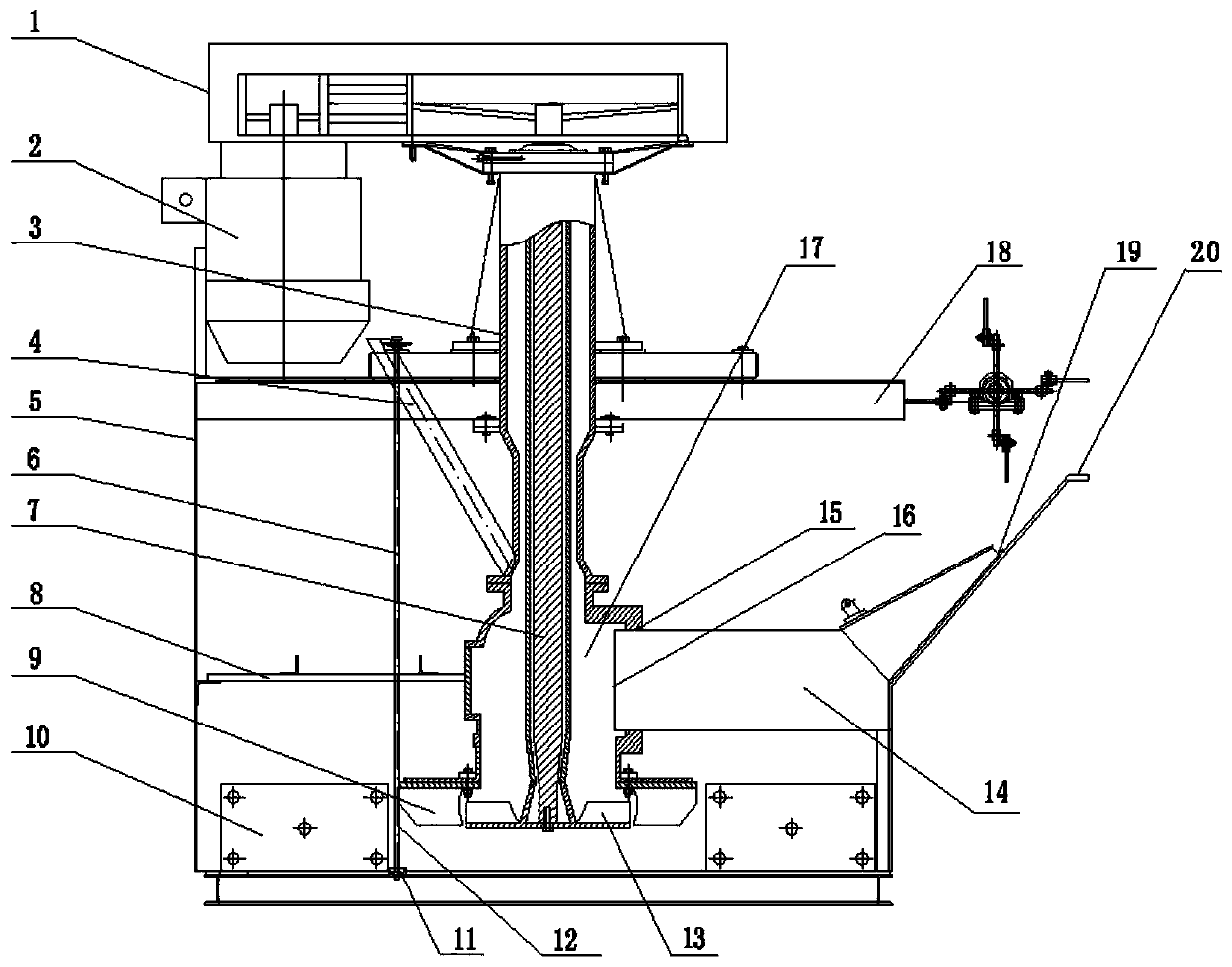

[0033] Embodiment 1, with reference to Figure 1-11 , a flotation machine used for flotation of coarse-grained materials, comprising a bracket 1 and a flotation cell body 5, an overflow weir 20 for foam overflow is arranged on one side of the flotation cell body, and an overflow weir is arranged above the overflow weir There is a bubble scraping device 18 for scraping foam, which is characterized in that it also includes:

[0034] The stirring mechanism includes a stirring rod 7 extending into the flotation cell body, the upper end of the stirring rod is connected with the driving device 2, and a stirring assembly is installed at the lower end of the stirring rod;

[0035] A sleeve 3 is sheathed on the stirring rod, and the annular chamber 17 formed between the sleeve 3 and the stirring rod 7 is used to transport air and ore pulp into the flotation cell body 5. The lower part is provided with at least one slurry inlet 15;

[0036] The circulation tank 14 is arranged under th...

Embodiment 2

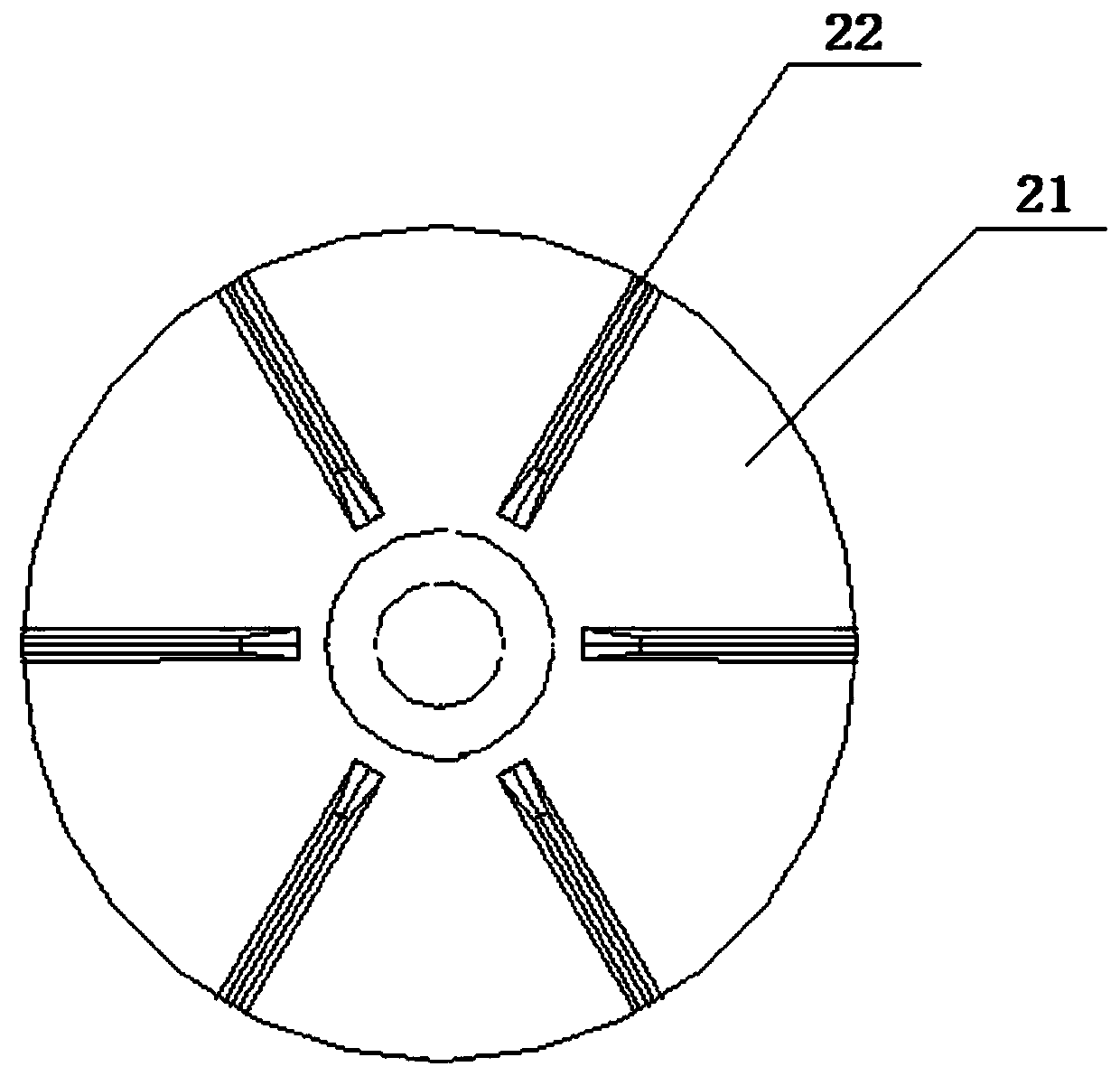

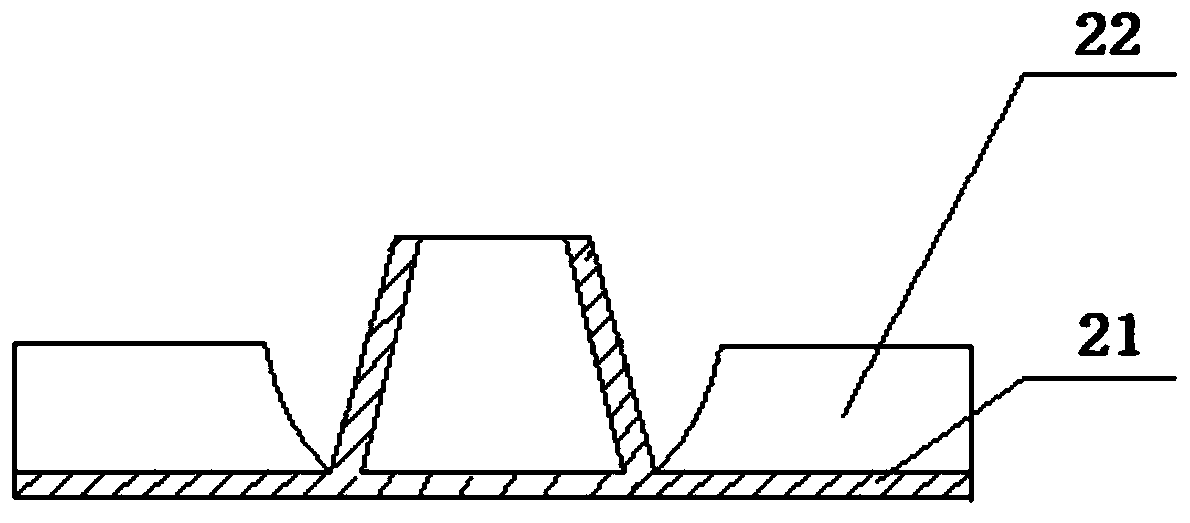

[0037] Embodiment 2, in a kind of flotation machine that is used for the flotation of coarse-grained material described in embodiment 1: described stirring assembly is arranged as stirring rotor 13, comprises disc-shaped rotor bottom plate 21 and several rotor blades 22, The rotor blades are mounted radially and annularly on the rotor bottom plate, and the rotor bottom plate is fixedly mounted on the bottom of the stirring rod; the ratio of the impeller diameter to the groove width of the stirring rotor is preferably set at 0.34-0.42.

Embodiment 3

[0038] Embodiment 3, in a kind of flotation machine used for the flotation of coarse-grained materials described in embodiment 1 or 2: a stirring stator 9 matched with a stirring rotor 13 is installed at the bottom of the sleeve 3, and the stirring stator It includes a disc-shaped stator base plate 23 and several stator blades 24, the stator blades are evenly distributed on the stator base plate in a ring shape, and each stator blade is deflected clockwise or counterclockwise by an angle of α, and the angle of α is preferably set to 20°- 40°, a stator reserved hole 25 for pulp flow is provided at the center of the stator bottom plate; the ratio of the impeller diameter to the groove width of the stirring stator is preferably set to 0.46-0.56.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com