Uniform speed flow sensor having flow signal amplifying function

A flow sensor and flow signal technology, which is applied in the direction of detecting fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, etc., can solve the problems of measurement signal fluctuation, small measurement signal, low sensitivity, etc., to eliminate fluctuations, The effect of large measurement signal and high measurement sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

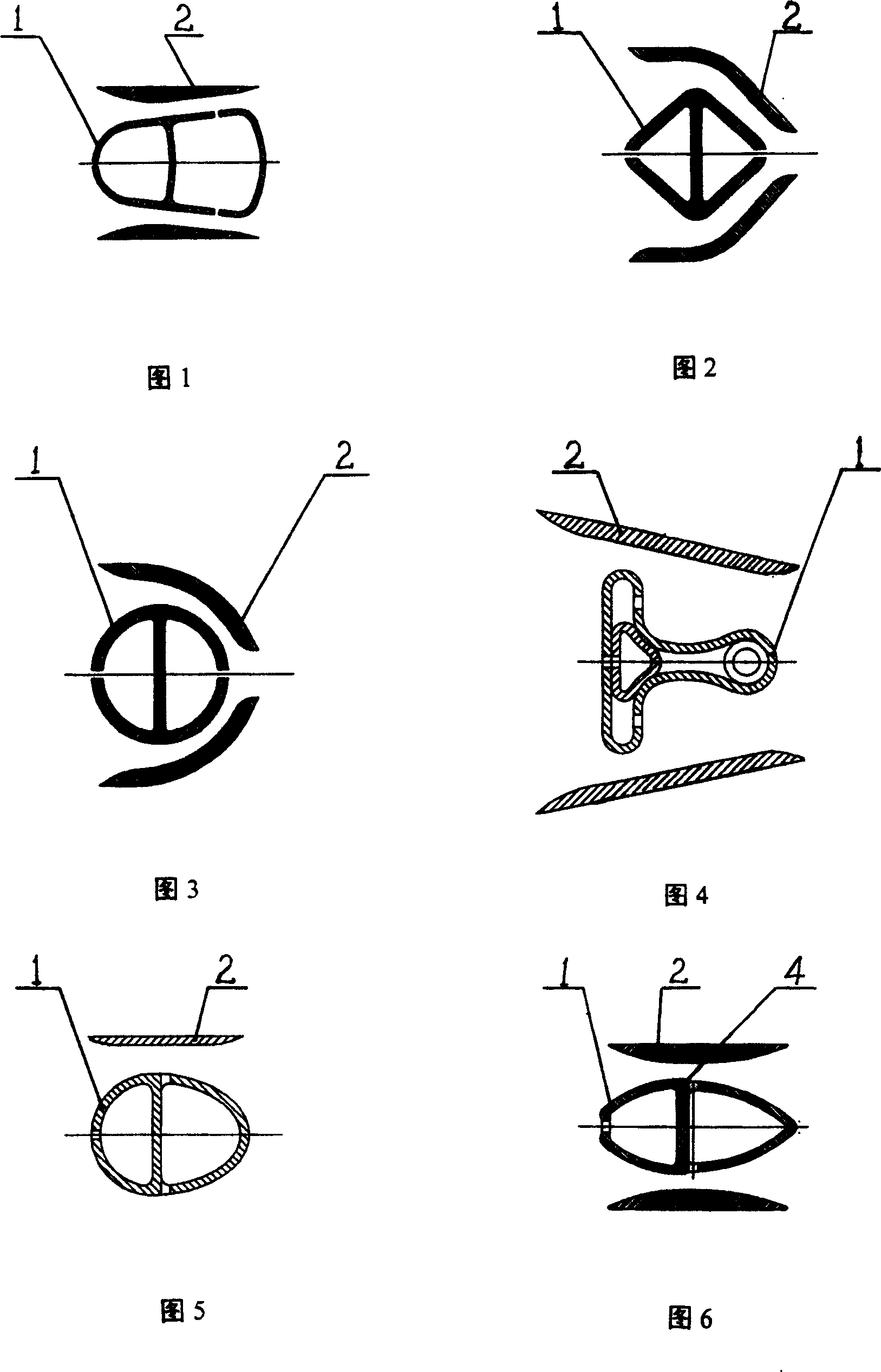

Embodiment 1

[0033] Referring to Fig. 1, the above-mentioned measuring rod 1 is in the shape of a Verabar bullet, and both sides of its symmetrical plane are provided with speed-up plates 2, which are arranged symmetrically, and the projection of the speed-up board 2 on the measuring rod 1 covers the measuring rod 1. superior. The inner side of the cross-section of the speed-increasing plate 2 is a combination of a protruding arc and a straight line, and the straight line is parallel to the surface of the static pressure-taking hole area on the measuring rod 1, so that the static pressure-taking hole is located at the speed-raising plate 2 and the measuring rod 1. In the minimum static pressure zone; the outside of said speed-up plate 2 section is a straight line.

Embodiment 2

[0036] See Figure 2: the above-mentioned measuring rod 1 is diamond-shaped, and the two sides of its symmetrical plane are provided with speed-increasing plates 2. The speed-increasing plates 2 are arranged symmetrically. The plate 2 is slightly extended on one side of the static pressure taking hole, so that the static pressure taking hole is located in the minimum static pressure zone formed by the speed increasing plate 2 and the measuring rod 1 . The inner side of the cross-section of the speed-increasing plate 2 is a concave streamline corresponding to the surface of the measuring rod 1, and the streamline can be formed by a protruding arc at both ends, a concave arc in the middle, and two straight lines between the arcs. Said that the outside of speed-up plate 2 cross-sections is streamlined corresponding to its inside.

Embodiment 3

[0038] Referring to Fig. 3, the above-mentioned measuring rod 1 is circular, and both sides of its symmetrical plane are provided with speed-increasing plates 2. The speed-increasing plates 2 are arranged symmetrically. The plate 2 is slightly extended on one side of the static pressure taking hole, so that the static pressure taking hole is located in the minimum static pressure zone formed by the speed increasing plate 2 and the measuring rod 1 . The inner side of said speed-up plate 2 cross-section is a streamline shape formed by three sections of arcs, the three sections of arcs are concave in the middle and convex at both ends, and the outside of said speed-up plate 2 cross-section is formed by one section of arc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com