Casting system for vacuum induction melting of high-temperature alloy and casting method thereof

A technology of vacuum induction melting and casting system, applied in the direction of casting mold, casting mold composition, casting equipment, etc., can solve problems such as difficulty in accurately controlling casting speed and solidification temperature, affecting product quality, etc., to ensure stability and continuity , The effect of reducing impurity involvement and uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

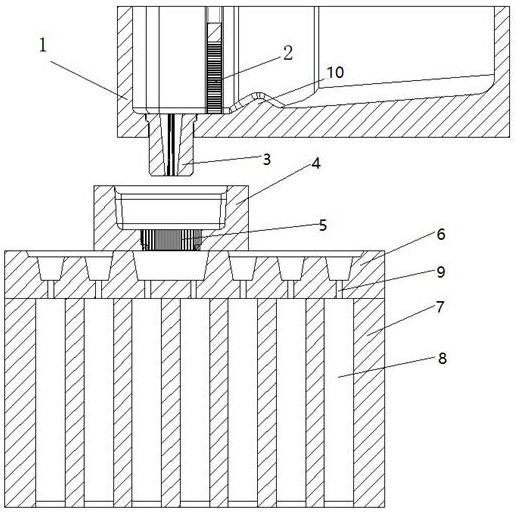

[0050] Design the size and diameter of the chute filter 2 in the casting system, the size of the lower outlet of the anti-vortex water outlet 3, the size and diameter of the zirconia honeycomb filter 5, and the diameter of the through hole of the diverter plate 6:

[0051] a. The size of the chute filter 2 is 130*100mm, the number of holes that can be used is 175, the hole diameter is φ4mm, and the cross-sectional area that the molten steel can pass is S 1 =Nπr 2 =175π*4≈2199mm 2 ≈22cm 2 , the effective cross-sectional area of molten steel depends on the retention of molten steel in the chute 1 and the speed at which molten steel is poured out from the melting crucible;

[0052] b. The diameter of the outlet of the anti-swirl water outlet 3 is φ28mm, and the cross-sectional area through which the molten steel can pass is S if the anti-swirl boss is removed. 2 ≈4.9cm 2 ;

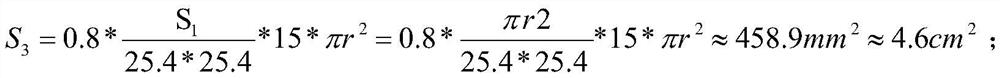

[0053] c. The zirconia honeycomb filter 5 is honeycomb-shaped, with a size of φ100*25mm, a pore dia...

Embodiment approach 2

[0058] Design the diameter of the through hole 9 of the distribution plate, taking the cast K 418 superalloy as an example, its density is ρ=8g / cm 3 .

[0059] a. Use a honeycomb zirconia honeycomb filter 5 with a size of φ100*25mm and a pore size of 15ppi. As calculated in Embodiment 1 above, the cross-sectional area of the zirconia honeycomb filter 5 that can pass through molten steel is S 3 =4.6cm 2 ;

[0060] b. In order to ensure the stability and continuity of the molten steel poured into the mold steel pipe 8 during the casting process, the passing cross-sectional area S of the aperture of the splitter plate 6 4 3 ;

[0061] c. The cross-sectional area S of the molten steel in the unit casting unit on the splitter plate 6 4 =Nπr 2 =4*π*r 2 3 ,but

[0062] d. The pouring temperature ensures the lowest possible superheat, so that the molten steel has sufficient fluidity in the mold steel pipe 8 without affecting the surface quality of the ingot, and at the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com