Bunsen burner capable of realizing multi-flame forms

A Bunsen burner and shape technology, applied in the field of laboratory equipment, can solve the problems of reducing the flame temperature, affecting the effect of combustion teaching experiment demonstration, not considering the improvement of the lamp tube and quantitative control of the gas, etc., so as to improve the flame temperature and enrich the teaching demonstration. Function, improve the effect of teaching demonstration experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

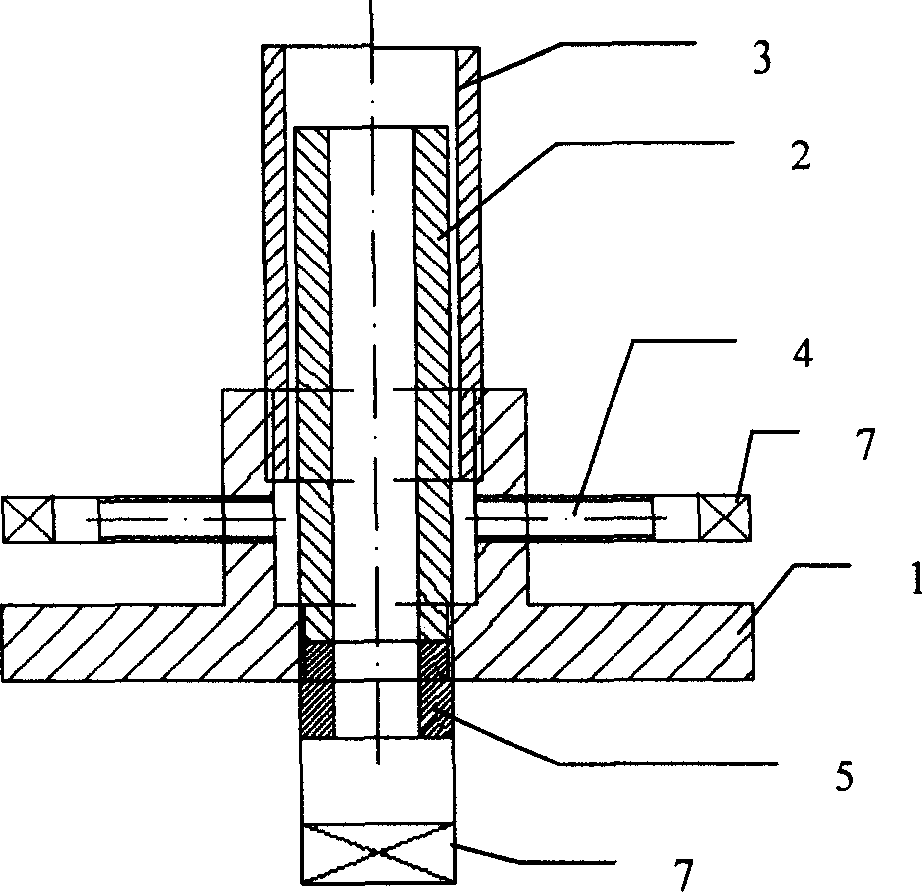

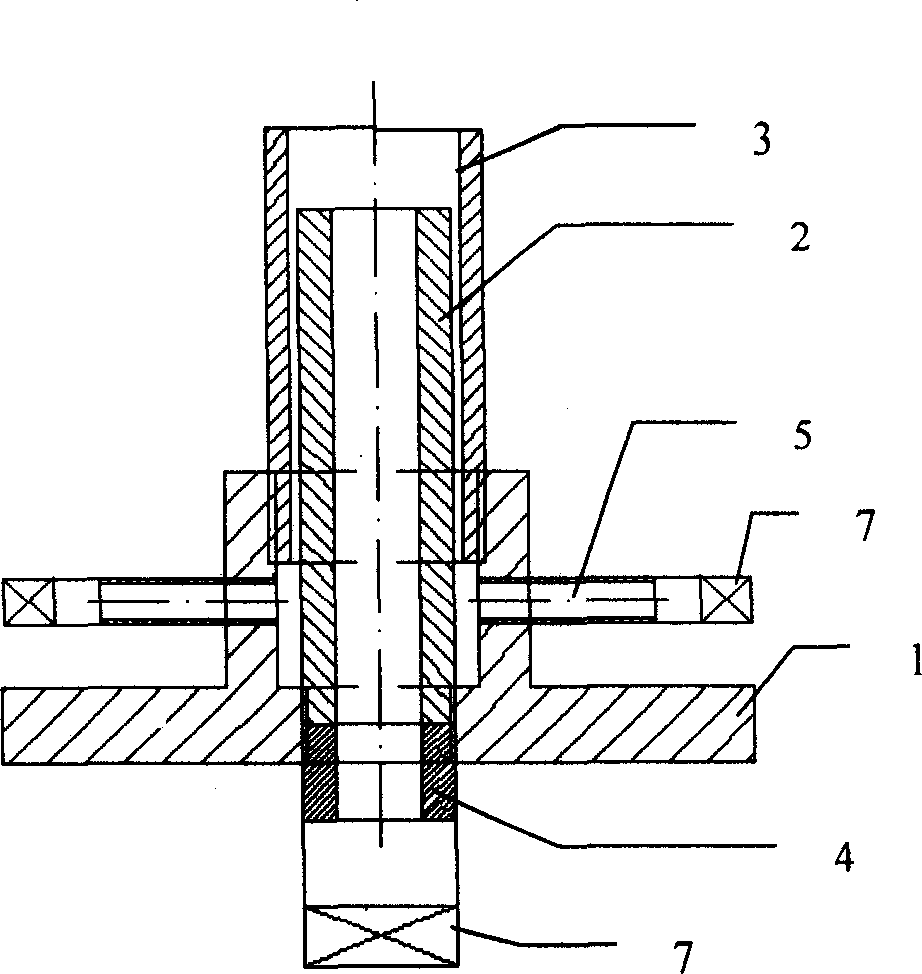

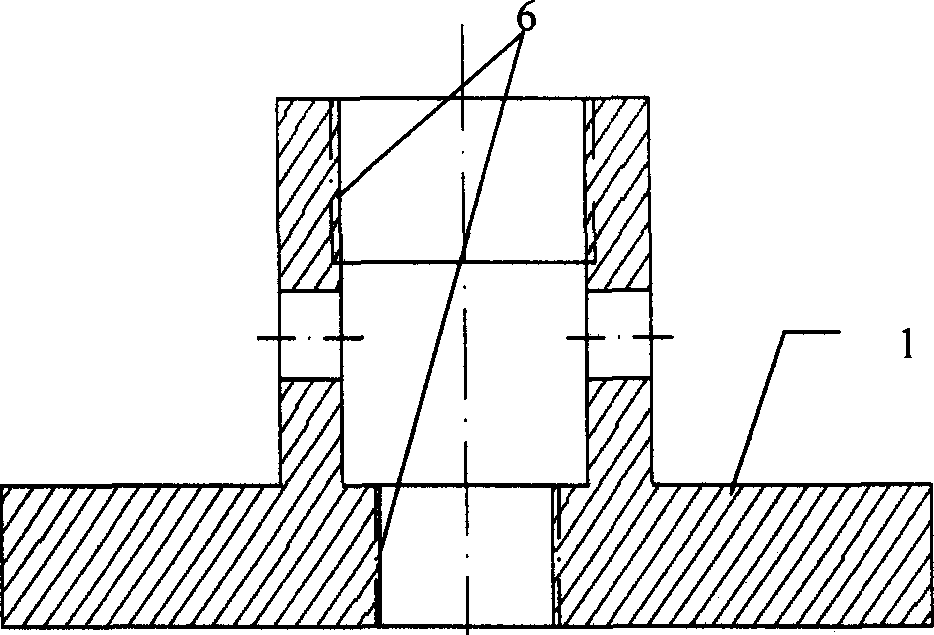

[0018] Embodiment 1: select the inner diameter d of the inner tube of the lamp to be 4 mm, the wall thickness to be 1 mm, and select the gap δ to be 1 mm, so that the inner diameter of the outer tube of the lamp is 8 mm; the length of the inner tube is selected to be 120 mm, and the length of the outer tube is selected to be 40 mm , then the height of the outer tube will be lower than the height of the inner tube, and the height difference Δl is -60 mm (the height difference of the concentric thread of the lamp holder Bunsen is 20 mm). Methane gas is used as the fuel gas, air is used as the supporting gas, the flow rate of methane is adjusted to 1L / min, and the flow rate of air is 3L / min to obtain a recommended diffusion flame.

Embodiment 2

[0019] Embodiment 2: The inner diameter of the inner tube of the lamp is selected to be 6 mm, the wall thickness is 2 mm, and the gap is selected to be 5 mm, so that the inner diameter of the outer tube of the lamp is 20 mm. The length of the inner tube is 220 mm, and the length of the outer tube is 200 mm (the height difference between the concentric threads of the lamp holder is 20 mm), so the inner and outer tubes are of the same height. Adjust the flow of methane to 0.1L / min and the flow of air to 7L / min to obtain a "comet" flame.

Embodiment 3

[0020] Embodiment 3: The inner diameter of the inner tube of the lamp is selected to be 10 mm, the wall thickness is 3 mm, and the gap is selected to be 10 mm, so that the inner diameter of the outer tube of the lamp is 36 mm. If the length of the inner pipe is 150 mm and the length of the outer pipe is 930 mm, then the outer pipe is higher than the inner pipe, and the height difference Δl is 800 mm. Adjust the flow rate of methane to 5 L / min and the flow rate of air to 40 L / min to obtain incomplete premixing flame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com