Composite element with a polymer connecting layer

A technology of composite parts and polymer materials, applied in the field of composite parts and footwear, can solve the problems of no contribution, increase the total quality of shoes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] introduction

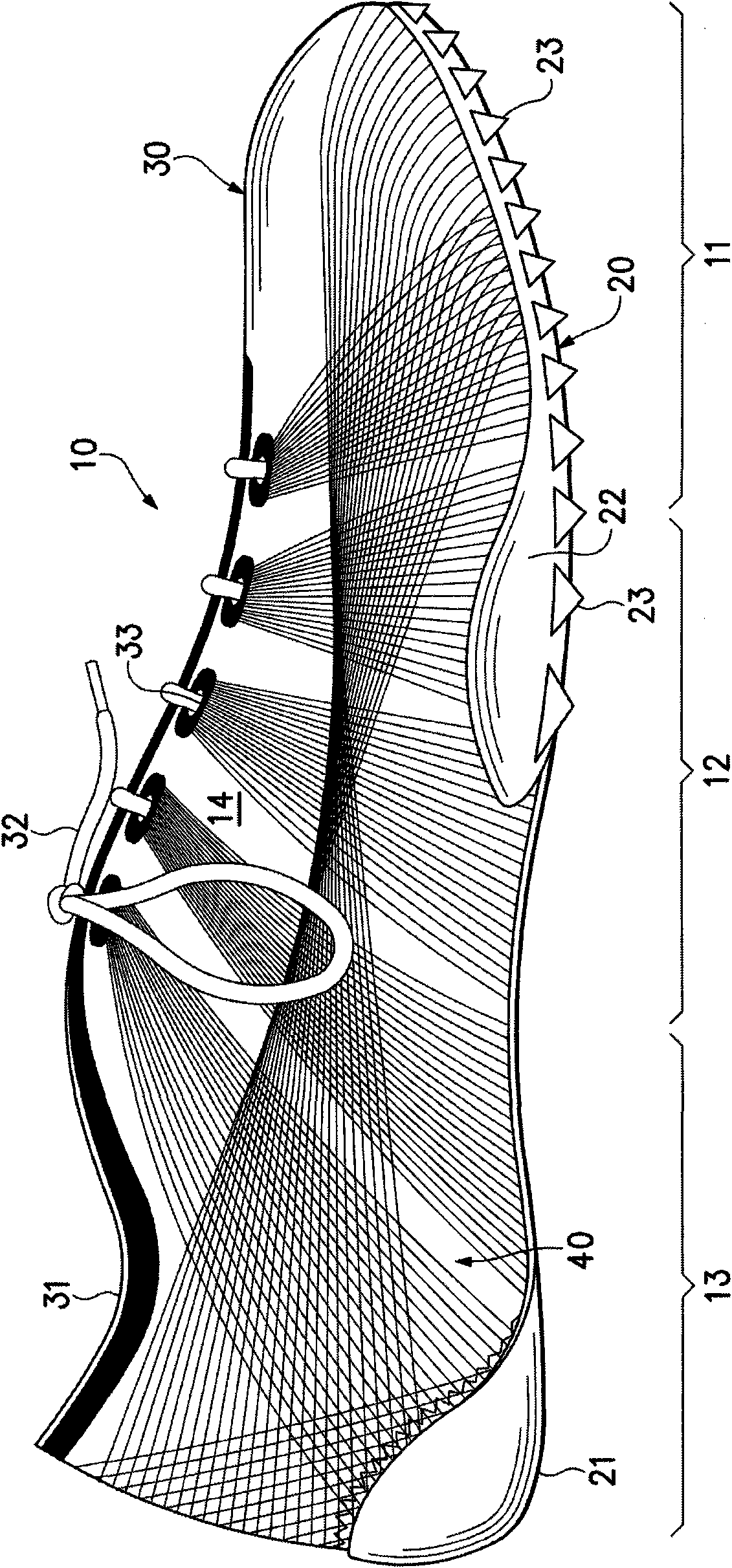

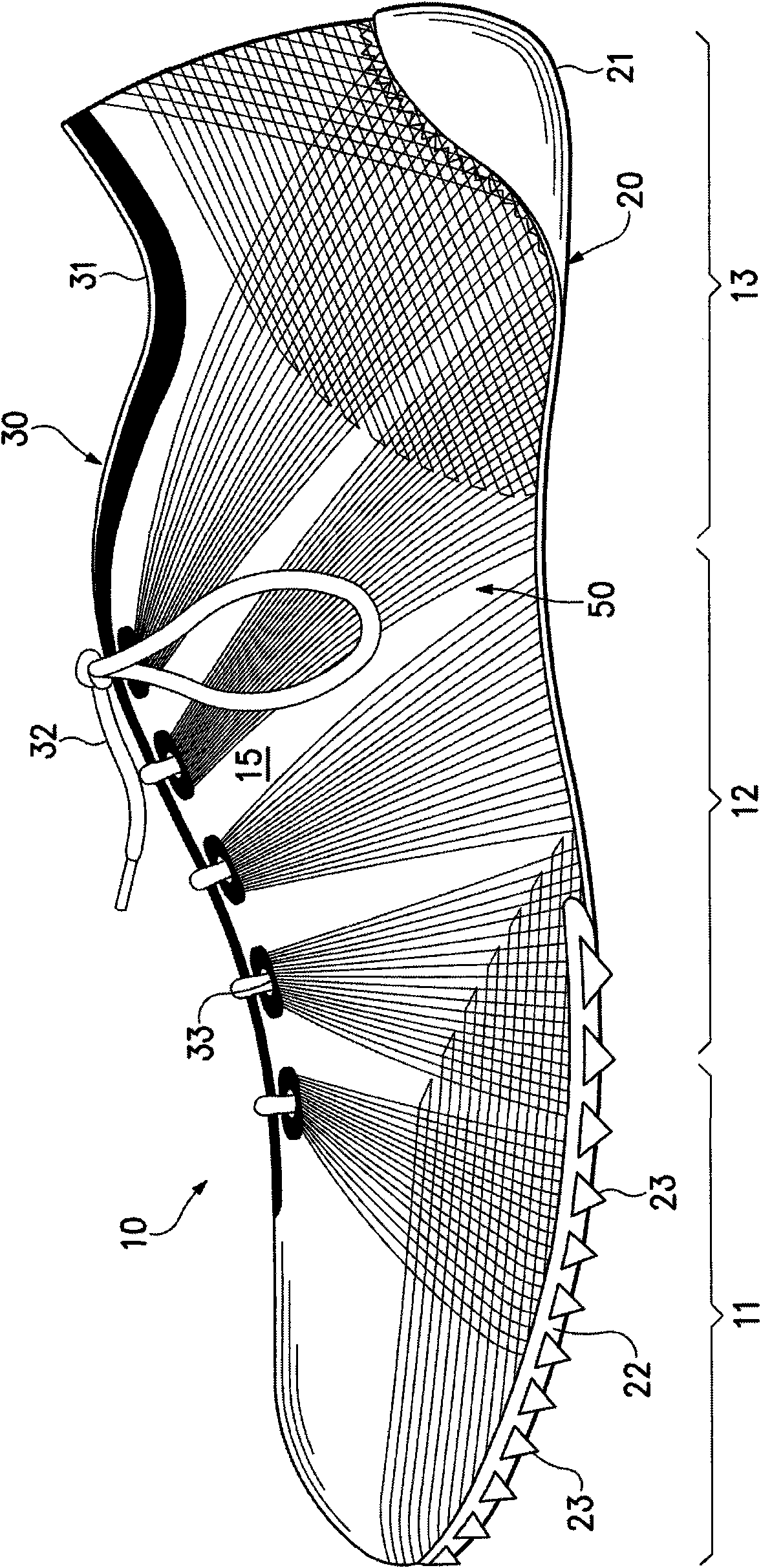

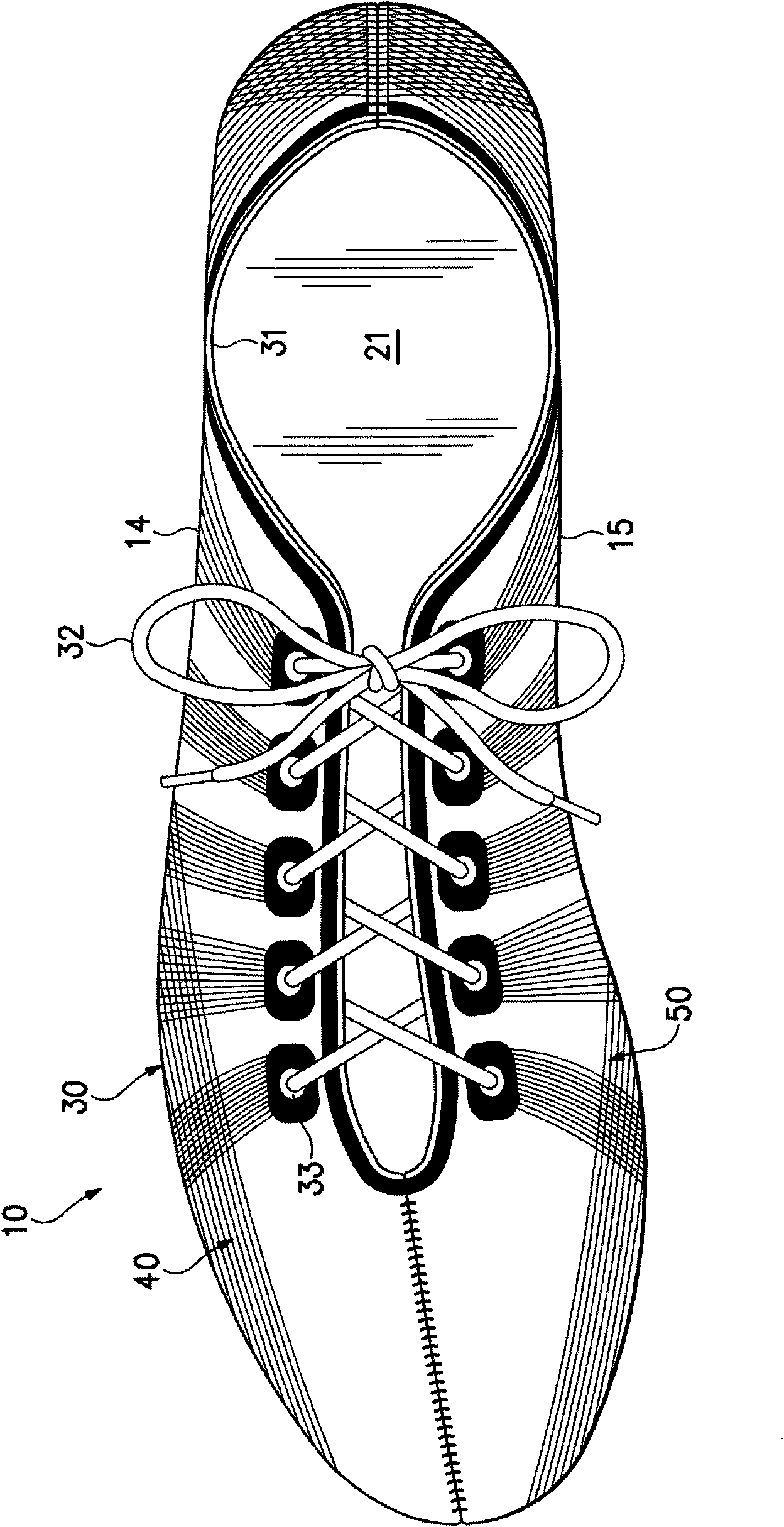

[0031] The following discussion and accompanying figures disclose an article of footwear having an upper with embroidered structures. Additionally, various methods of manufacturing the upper are disclosed. Uppers and methods are disclosed with reference to footwear having a structure suitable for running, especially sprinting. However, concepts related to uppers are not limited to footwear designed for running, but can be applied to a wide range of athletic shoe styles including, for example, baseball shoes, basketball shoes, multipurpose training shoes, cycling shoes, soccer shoes, tennis shoes, Rugby shoes, walking shoes and hiking boots. The concept can also be applied to footwear styles generally considered non-athletic, including dress shoes, loafers, sandals, and work boots. Accordingly, the concepts disclosed herein are applicable to a variety of footwear styles. Additionally, the concepts disclosed herein may be applied to products other than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com