Preparation method of nano silicon-carbon negative electrode material

A technology of carbon anode material and nano-silicon, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complicated process and affecting the performance of final products, and achieve simple process, reduce attenuation, Avoid the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

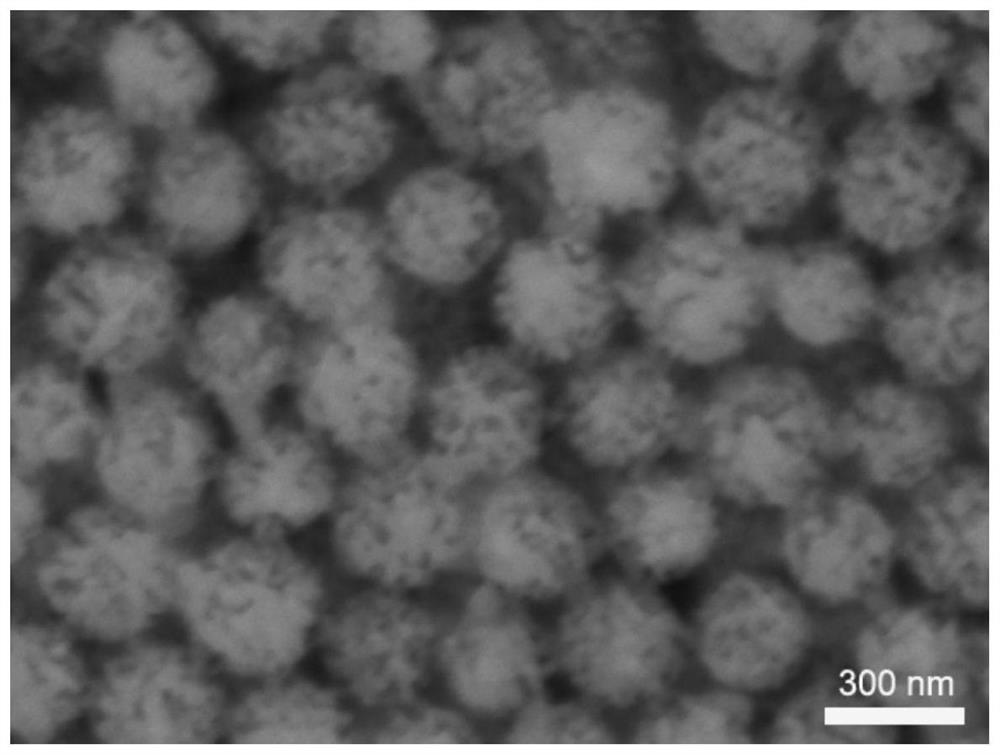

Embodiment 1

[0044] Mix tetraethyl orthosilicate with ammonia water at a mass ratio of 8:2, and react at a constant temperature of 28°C to prepare nano-SiO 2 , prepared containing nano-SiO 2 Microsphere solution, after washing, take 1g nano-SiO 2 Disperse the solution in 170ml of deionized water, ultrasonically disperse for 10min, add 10.5mg of styrene monomer, and 0.35mg of methacrylic acid, mix thoroughly with electromagnetic stirring, heat in a water bath at 80°C, keep the temperature for 30min, then add 0.037mg of potassium persulfate, Stir at a constant speed under the protection of nitrogen, react at a constant temperature of 80° C. for 10 h, and then cool to room temperature to obtain polymer microspheres with nano-Si as the core. After washing with deionized water, it was vacuum filtered and dried in an oven at 50°C for 12 hours. After grinding, pass through a 400-mesh sieve to obtain coated nano-SiO 2 Particles to obtain the nano-silicon-carbon precursor Put the above-mentioned...

Embodiment 2

[0048] Mix tetraethyl orthosilicate with ammonia water at a ratio of 7:3, and react at a constant temperature of 28°C to prepare nano-SiO 2 , prepared containing nano-SiO 2 The solution of the microspheres, after washing, was taken containing 2g nano-SiO 2 solution, ultrasonically dispersed for 10 minutes, added 10.5 mg of styrene monomer, and 0.35 mg of methacrylic acid, mixed thoroughly with electromagnetic stirring, heated in a water bath at 80°C, and kept at a constant temperature for 30 minutes, added 0.040 mg of potassium persulfate, stirred at a constant speed under nitrogen protection, 80 ℃ constant temperature reaction for 10h, cooled to room temperature, and freeze-dried to obtain coated nano-SiO 2 For the microspheres, pass the microspheres through a 400-mesh sieve to obtain a nano-silicon-carbon precursor. The above-mentioned nano-silicon-carbon precursor and 1.6g of magnesium powder were put into crucibles respectively, then placed in an electric furnace, protec...

Embodiment 3

[0051] Mix tetraethyl orthosilicate and ammonia water at a ratio of 6:4, and react at a constant temperature of 28°C to prepare nano-SiO 2 , prepared containing nano-SiO 2 For the solution of microspheres, after washing, take a solution containing 4g of nano-SiO2, add 0.4g of glucose to obtain a uniformly dispersed mixed solution; dry the mixed solution at 105°C for 24h, remove water, and obtain dry nano-SiO2 coated with glucose. 2 particles. After crushing with a ball mill, pass through a 400-mesh sieve to obtain glucose-coated nano-SiO 2 microspheres to obtain nano-silicon carbon precursors. Put the SiO2 and 3.2g magnesium powder in the above granules into crucibles respectively, then place them in an electric furnace under argon protection, heat up to 850°C at a heating rate of 15°C / min, keep the temperature constant for 2 hours, take it out after cooling. That is, the nano-silicon-carbon negative electrode material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com