A preparation method of a through-hole type lithium battery negative electrode material

A negative electrode material, lithium battery technology, applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of structure collapse and pulverization, unstable solid electrolyte interface, product cycle performance decline, etc., to achieve a mild reaction process, The effect of continuous electron diffusion path and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

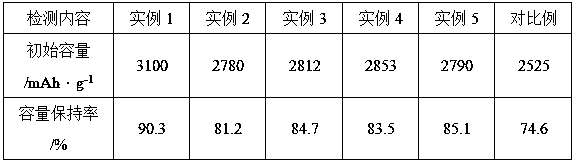

Examples

example 1

[0021]In parts by weight, take 30 parts of titanate, 60 parts of silicate, 200 parts of glycerin, and 10 parts of gelatin, first pour the gelatin and glycerin into a beaker, and place the beaker on a digital speed measuring constant temperature magnetic stirrer, At a temperature of 50°C and a rotation speed of 600r / min, heat and stir to dissolve for 60 minutes, then pour the material in the beaker into a three-necked flask, and add titanate and silicate into the three-necked flask, and then heat at 85 ℃, the rotation speed is 600r / min, after heating and stirring for 5 hours, under the pressure of 500mmHg and the temperature of 180℃, the residual glycerin is removed by concentration under reduced pressure, the material is discharged, cooled, and the refined concentrate is obtained; the obtained refined concentrate The sulfuric acid solution with a mass fraction of 50% is mixed and poured into a hydrothermal kettle, and then the hydrothermal kettle is sealed. Under the conditions...

example 2

[0023] In terms of parts by weight, take 60 parts of silicate, 200 parts of glycerin, and 10 parts of gelatin in sequence. First, pour the gelatin and glycerin into a beaker, and place the beaker on a digital speed measuring constant temperature magnetic stirrer at a temperature of 50 ° C. At a rotation speed of 600r / min, heat and stir to dissolve for 60min, then pour the material in the beaker into a three-necked flask, and add silicate into the three-necked flask, then at a temperature of 85°C and a rotation speed of 600r / min, After heating and stirring for 5 hours, at a pressure of 500mmHg and a temperature of 180°C, concentrate under reduced pressure to remove residual glycerin, discharge the material, and cool to obtain a refined concentrate; the obtained refined concentrate and a sulfuric acid solution with a mass fraction of 50% Mix and pour into the hydrothermal kettle, then seal the hydrothermal kettle, under the conditions of temperature 180°C, pressure 1.6MPa, rotati...

example 3

[0025] In parts by weight, take 30 parts of titanate, 60 parts of silicate, 200 parts of glycerin, and 10 parts of gelatin, first pour the gelatin and glycerin into a beaker, and place the beaker on a digital speed measuring constant temperature magnetic stirrer, At a temperature of 50°C and a rotation speed of 600r / min, heat and stir to dissolve for 60 minutes, then pour the material in the beaker into a three-necked flask, and add titanate and silicate into the three-necked flask, and then heat at 85 ℃, the rotation speed is 600r / min, after heating and stirring for 5 hours, under the pressure of 500mmHg and the temperature of 180℃, the residual glycerin is removed by concentration under reduced pressure, the material is discharged, cooled, and the refined concentrate is obtained; the obtained refined concentrate The sulfuric acid solution with a mass fraction of 50% is mixed and poured into a hydrothermal kettle, and then the hydrothermal kettle is sealed. Under the condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com