Horizontal lead-acid battery with filler and assembly method thereof

A technology of lead-acid battery and assembly method, which is applied in the field of storage batteries, can solve the problems of contact short circuit of positive and negative plates, short circuit of plates, etc., and achieve the effects of avoiding short circuit, simple steps and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

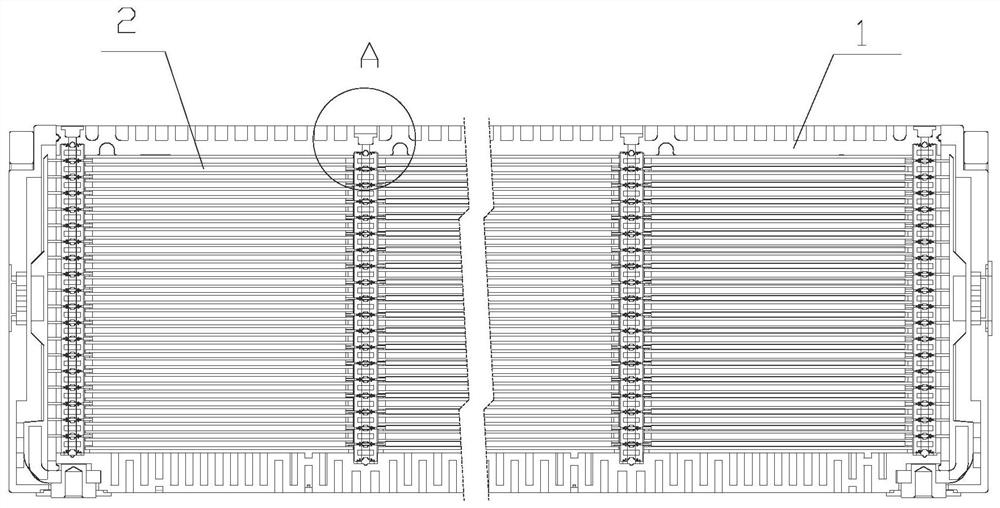

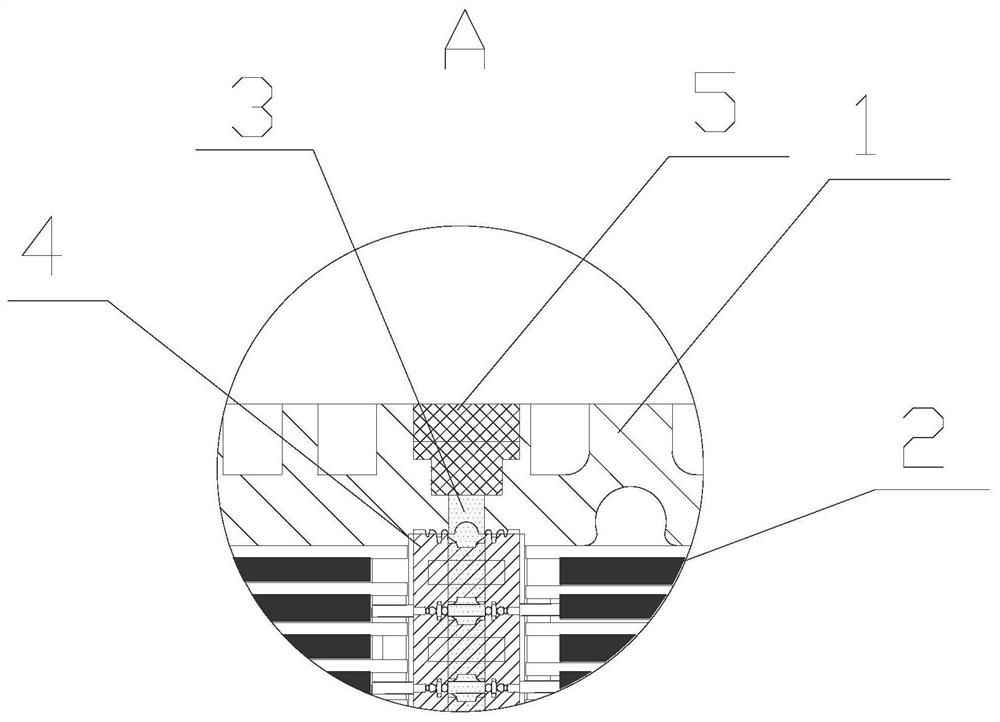

[0036] A horizontal lead-acid battery with a filling such as figure 1 and figure 2 As shown, it includes a battery casing 1, and a battery pole group composed of positive plates 2 (positive and negative plates) and a separator. The two ends of each battery pole group are provided with a physical barrier formed by a number of separators 4, and all the pole plates 2 is surrounded by fillings.

[0037] The separator is a strip-shaped structure composed of an elastic matrix and an insert wrapped inside the elastic matrix. The height of the strip-shaped structure is equivalent to the distance between the horizontal lead-acid battery plates. The positions corresponding to the inner surfaces of the bottom plate, side plates, and top cover and the spacers (i.e. physical barriers) are all provided with spacer positioning grooves, and the upper and / or lower ends of the strip-shaped structures are provided with left and right penetrating holes for accommodating A groove for accommodat...

Embodiment 2

[0051] In Example 2, the filler is 1-10wt% sodium alginate solution, which is viscous paste before solidification, and has a certain fluidity after high-speed stirring and shearing. It is vacuum pumped into the inner cavity of the battery, and after 5A charging for 6 hours, Due to the dehydration effect, a jelly-like elastic body is formed, and the elastic body is further dehydrated and hardened during the charging and discharging process of the battery.

Embodiment 3

[0053] In Example 3, the filler is epoxy glue, which is a liquid with very low viscosity and good fluidity before curing, at a constant temperature of 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com