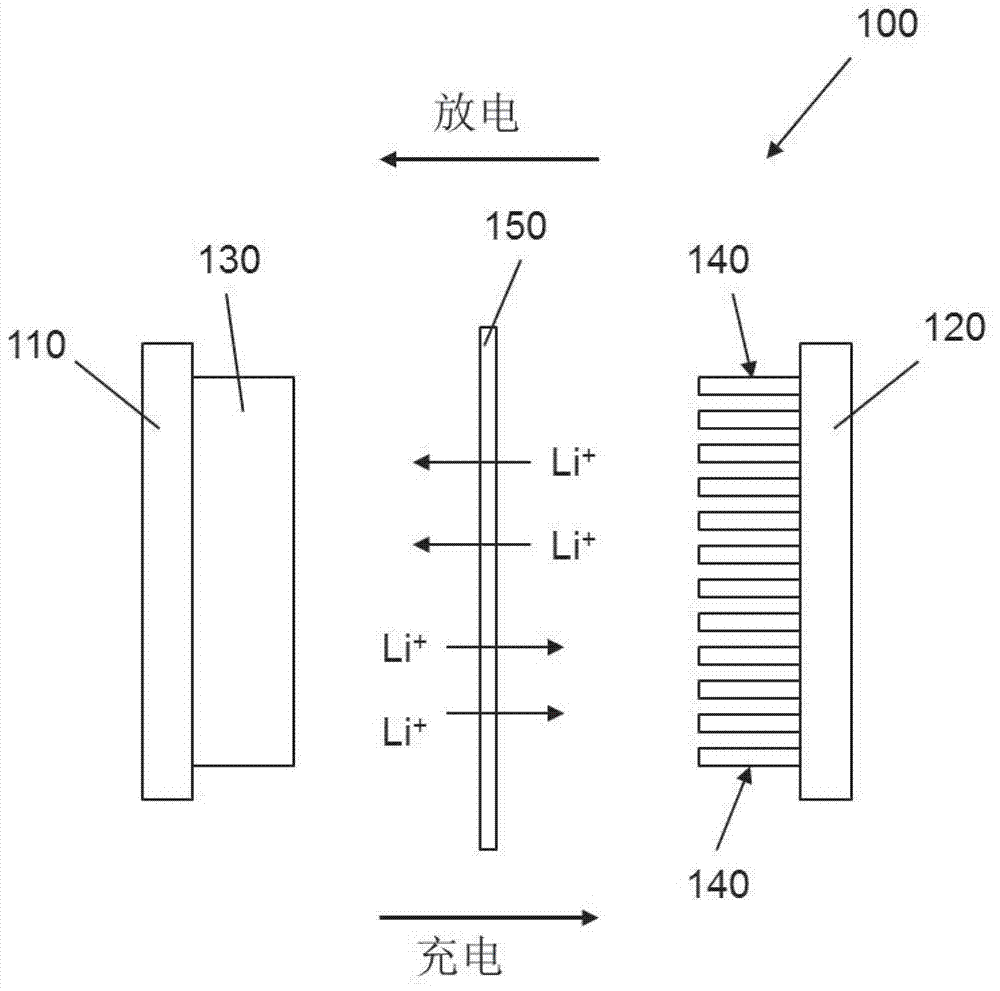

Modified battery anode with carbon nanotubes

A technology of carbon nanotubes and battery negative electrodes, which is applied in the field of lithium-ion battery technology and nanomaterials, and can solve problems such as battery failure, negative electrode loss, and negative electrode material rupture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

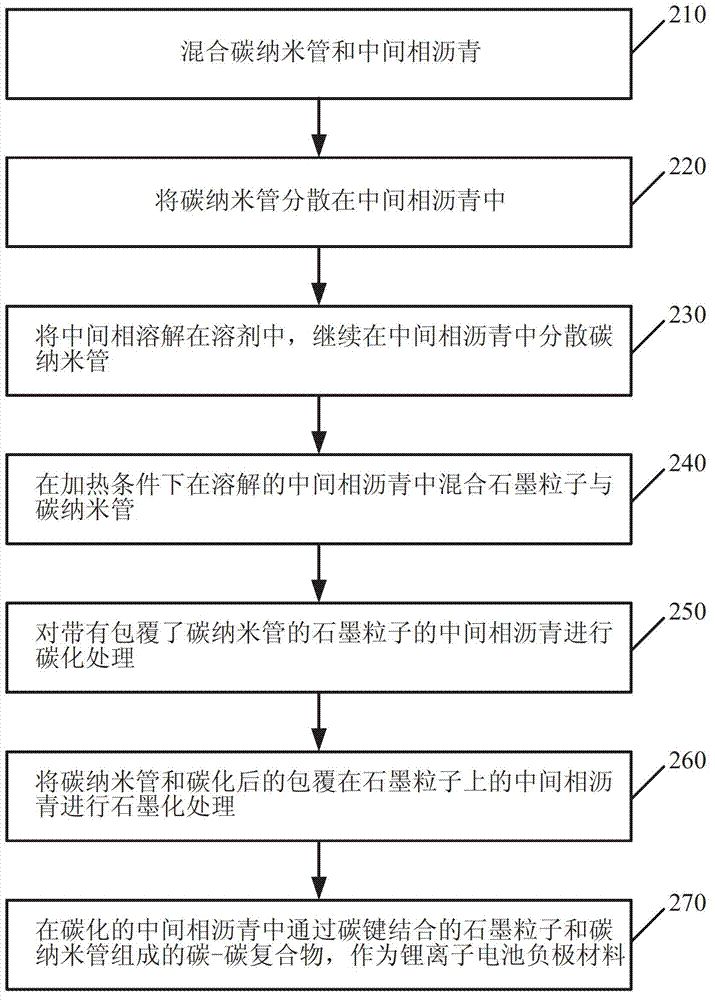

Method used

Image

Examples

Embodiment 1

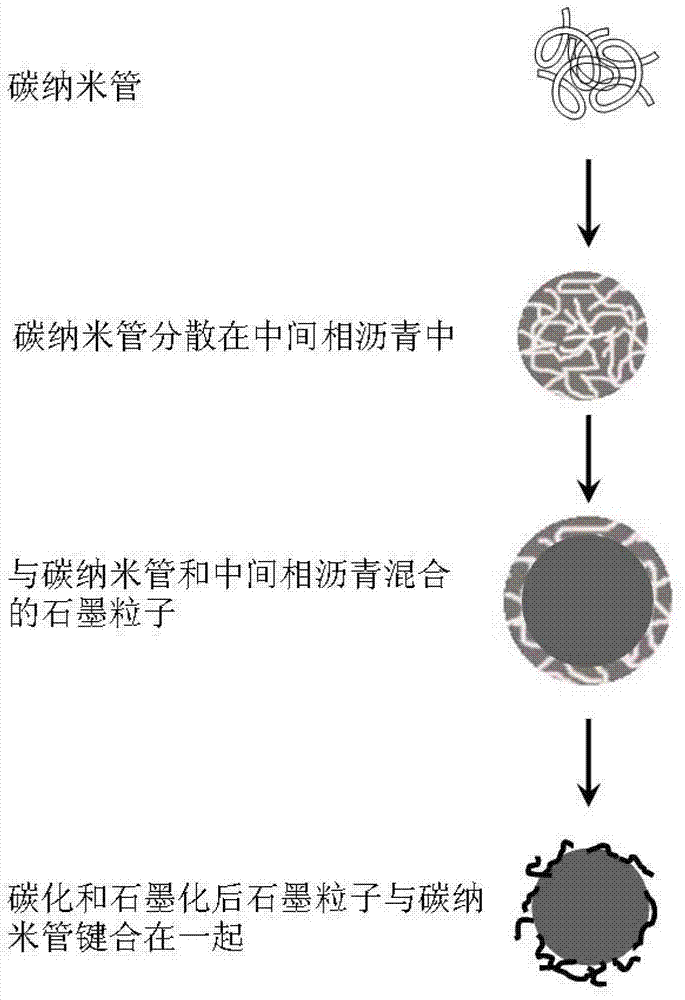

[0051] Example 1. Mixing carbon nanotubes and mesophase pitch by solid pulverization

[0052] In this example, the carbon nanotubes and pitch pieces were first conveyed into a jet mill at a ratio of 1 / 10. Pulverization is then carried out at a rotational speed higher than 45 Hz. After crushing, the carbon nanotubes can be seen mixed with powdered pitch particles.

Embodiment 2

[0053] Example 2. Mixing carbon nanotubes and pitch by liquid processing

[0054] Although pitch is not uniform in chemical composition, it is soluble in many solvents, including xylene, among others. In a container, a predetermined amount of bitumen is first mixed with xylene. The amount of asphalt added in xylene is about 20%. When all the pitch particles were dissolved in the solvent, carbon nanotubes were added to the solution at a ratio (CNT / pitch) of 1 / 5 (20% carbon nanotubes in the paste). The resulting paste is then sent to a ball mill or three-roll mill for further dispersion.

Embodiment 3

[0055] Example 3. Mixing of carbon nanotubes and epoxy resin by twin screw extruder

[0056] The twin-screw extruder is a general-purpose mixing machine used in the plastics industry. The prior art has disclosed techniques for dispersing carbon nanotubes in plastics and epoxy resins. Typically, carbon nanotubes and epoxy resin are fed into a twin-screw extruder from separate inlets. The melted epoxy resin moves the carbon nanotubes to the dispersion area, where the designed helical structure generates a suitable shear force to open the agglomerated carbon nanotubes and disperse them in the epoxy resin. The molten epoxy resin containing dispersed carbon nanotubes is eventually extruded out of the device and cut into pellets after cooling to cryogenic temperatures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com