Heat-insulating airbag for a van

A van and airbag technology, applied in the field of machinery, can solve problems such as the inability to judge the degree of fit between the airbag and the van, the incomplete fit of the airbag and the van, poor thermal insulation of the airbag, etc. problems, to achieve good elasticity, ensure sealing, and improve the effect of heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

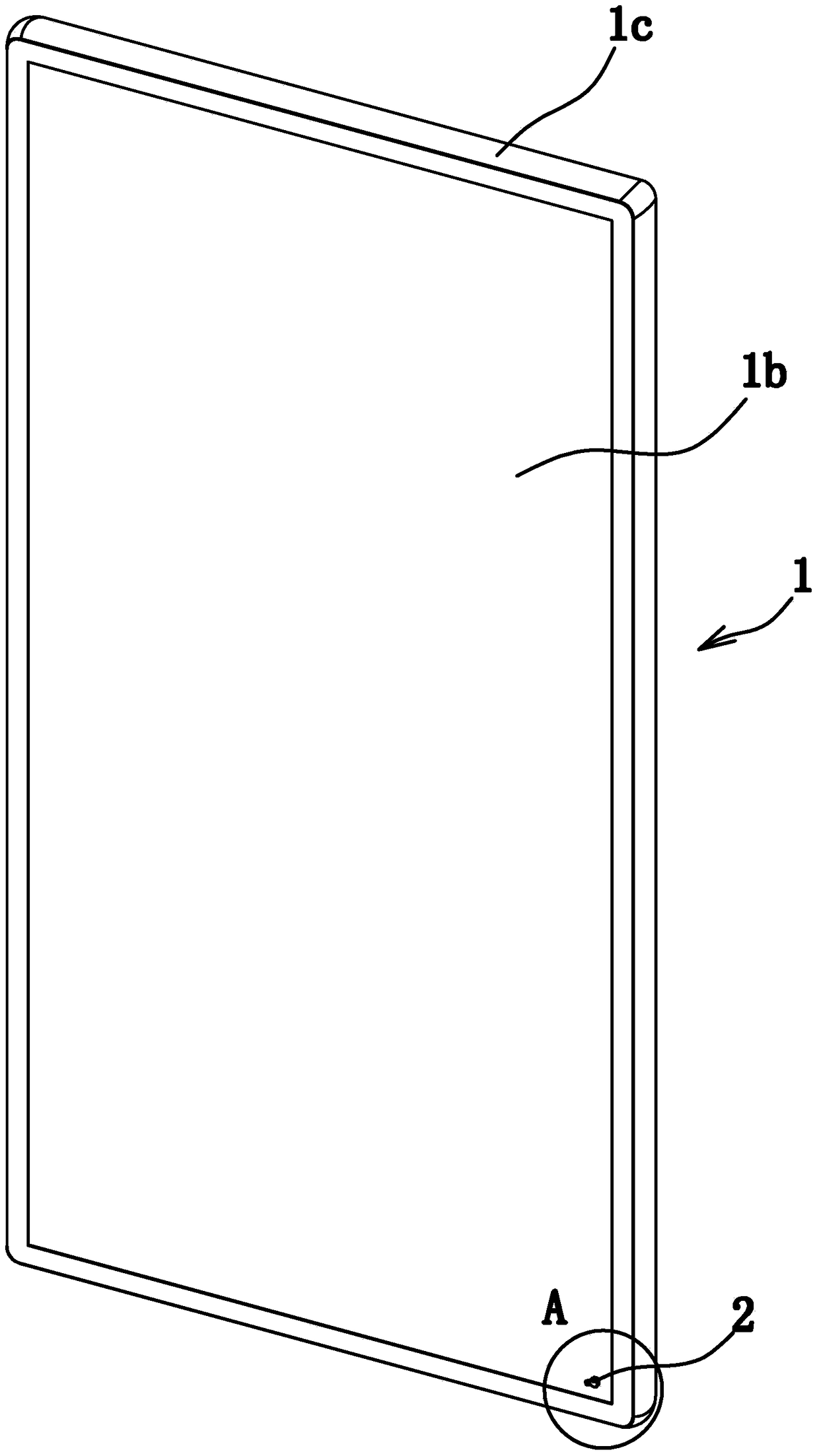

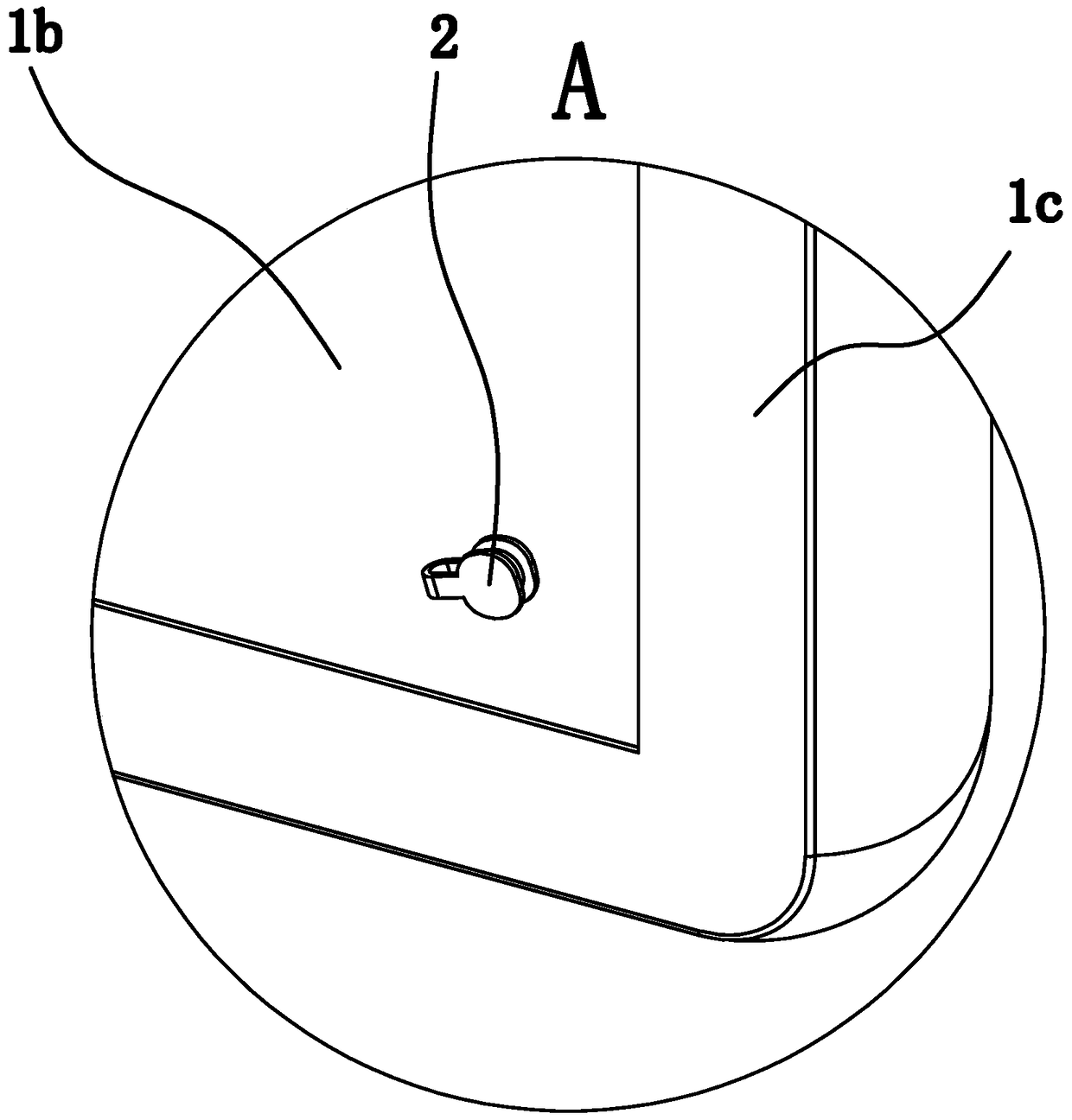

[0036] Such as figure 1 with figure 2 As shown, the heat insulation airbag used on the van is composed of a body 1 with a closed air chamber 1a, and the body 1 is in the shape of a rectangular plate when inflated. Such as figure 2 As shown, the body 1 is provided with an air nozzle 2 communicating with the inflation cavity 1 a, and in actual use, the body 1 is inflated or deflated through the air nozzle 2 .

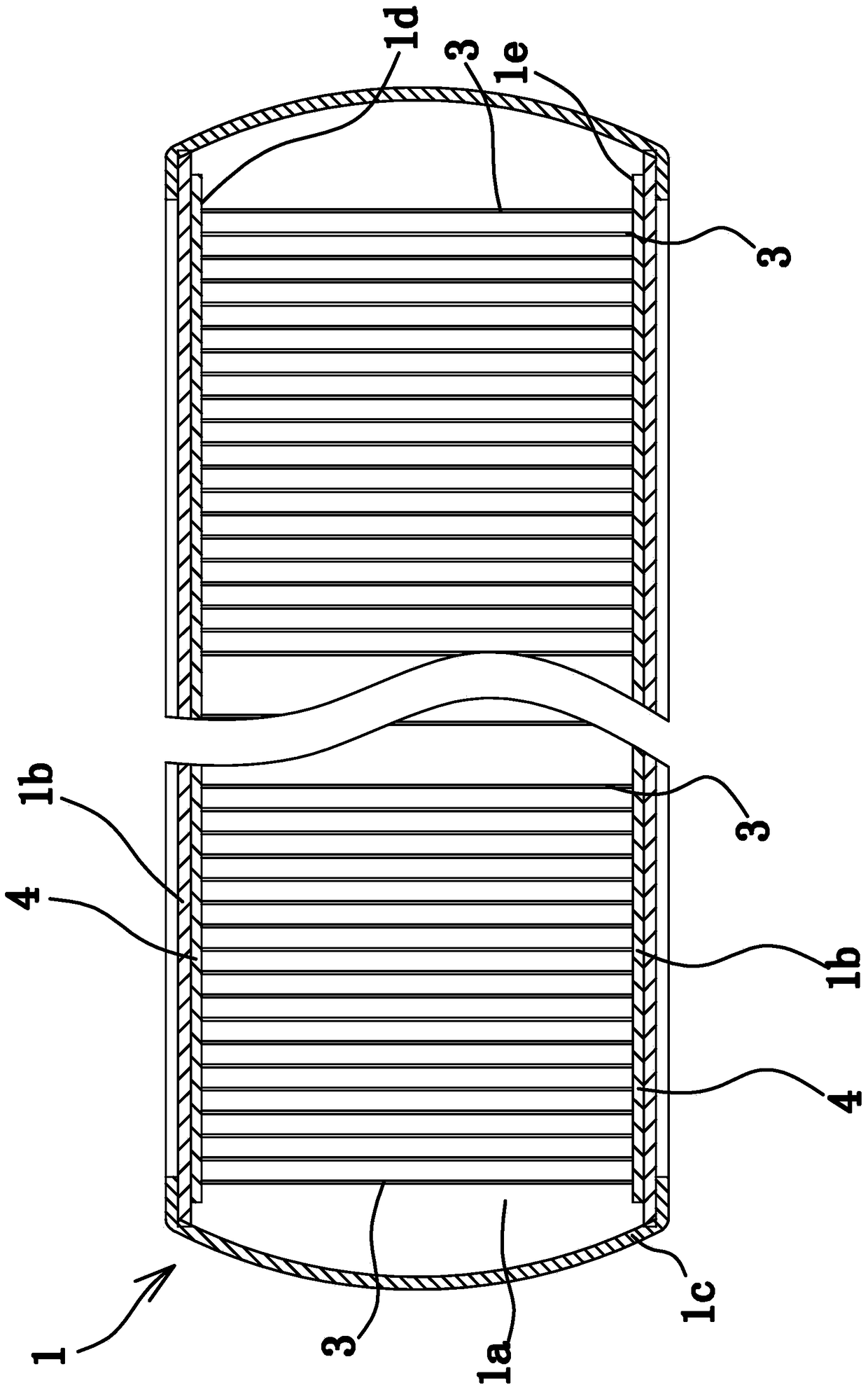

[0037] Specifically, as image 3 with Figure 4 As shown, between the front side 1e of the body 1 and the rear side 1e of the body 1, there is a strip-shaped flexible piece 3, that is, the flexible piece is located in the inflatable cavity 1a, there are multiple flexible pieces 3, and multiple flexible pieces 3 are arranged parallel to each other. The lengths of each flexible piece 3 are approximately equal, and the two ends of each flexible piece 3 are respectively fixed to the front side 1d of the main body 1 and the rear side 1e of the main body 1 . In this exa...

Embodiment 2

[0043] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that the flexible part 3 is a leather strip, and the two ends of the leather strip are fixedly connected with the two connecting pieces 1b respectively, and the leather strip is used as the flexible part 3, and the leather strip It also has the advantage of not being easily deformed, and can effectively ensure that the shape of each expansion of the airbag is a rectangular plate, which improves the heat insulation and heat preservation effects of the heat-insulating airbag.

Embodiment 3

[0045] The structure and principle of the third embodiment are basically the same as those of the first embodiment, the difference is that: Figure 4 with Figure 5 As shown, a Velcro 5 and a handle 6 are fixedly attached to the outer wall of the connecting piece 1b. The handle 6 is made of flexible material, and the flexible material can be leather, cowhide and the like. When the airbag is not in use, the entire airbag can be rolled up into a columnar shape, and the fluffy surface on the Velcro 5 and the hook-shaped surface are bonded together to keep the rolled up airbag in a columnar shape, which improves the convenience of carrying the airbag sex. By providing the handle 6, it is convenient for the user to exert force on the airbag, so as to facilitate the detachment of the airbag from the van compartment or to facilitate the carrying of the airbag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com