Preparation method of silicon-titanium dioxide-graphene flexible self-supporting electrode

A self-supporting electrode, titanium dioxide technology, used in battery electrodes, secondary batteries, circuits, etc., can solve the problem of difficult to obtain uniform and stable composite electrodes, and achieve the effect of reducing the quality of the pole piece, improving the mechanical properties, and improving the conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

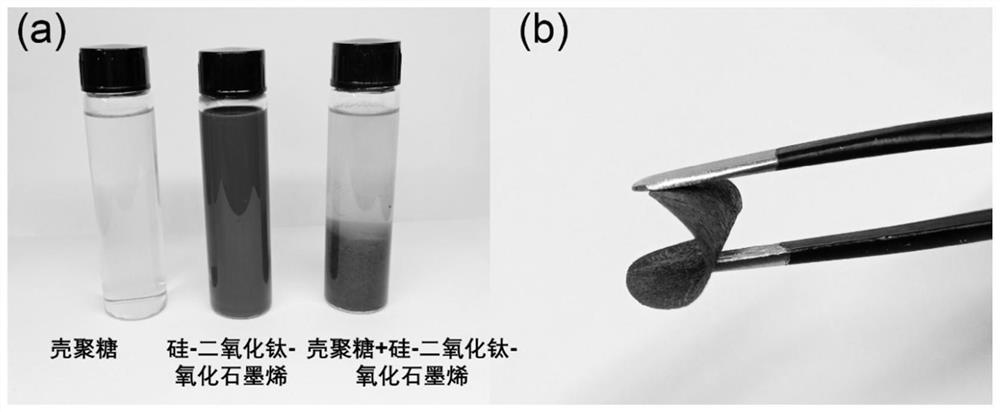

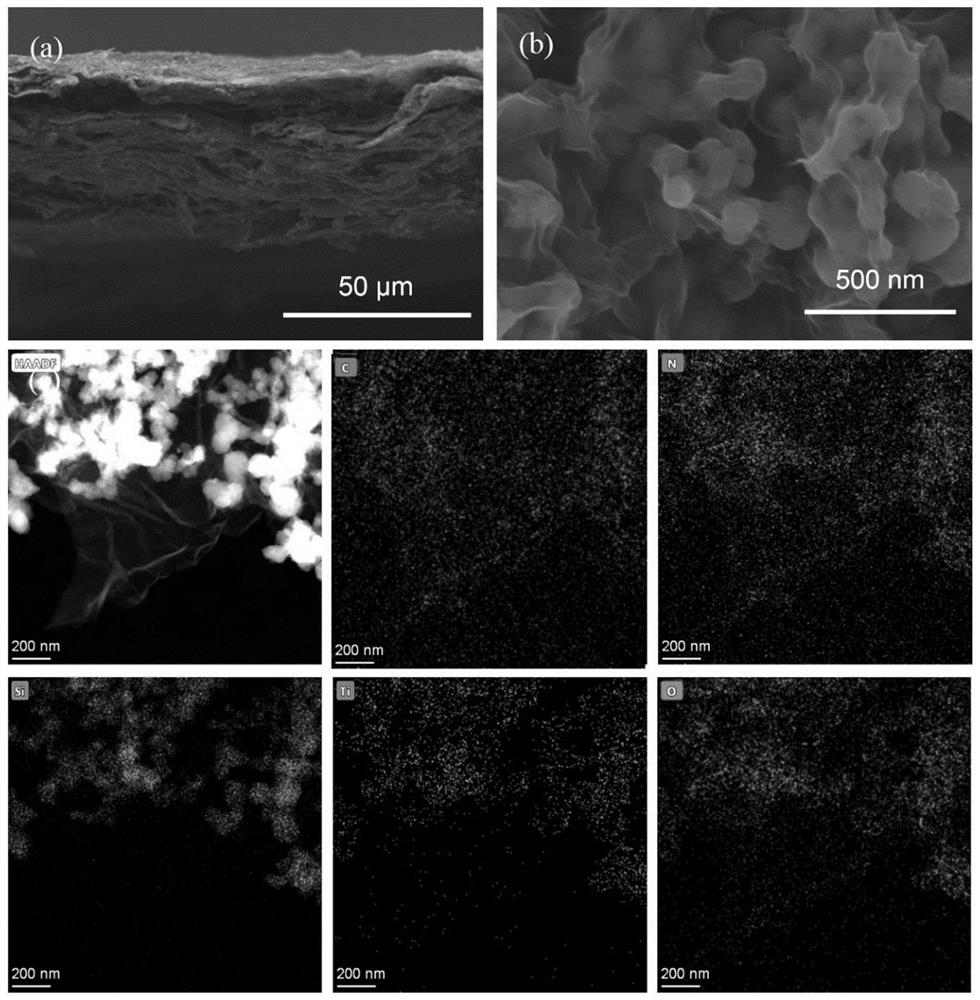

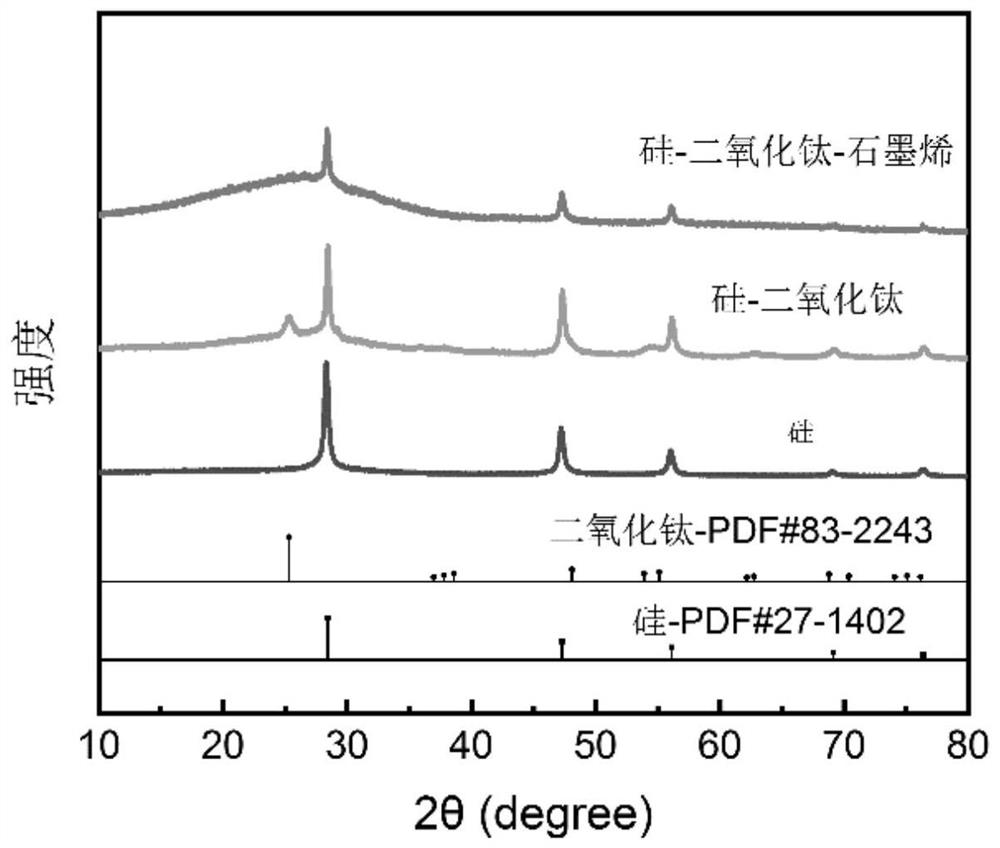

[0033]1) ultrasonically treat the graphite oxide filter cake with an average size of 150 μm in water, the ultrasonic frequency is 50 kHz, and the time is 1 h to prepare a graphene oxide dispersion liquid of 5 mg / mL; meanwhile, the concentrated sulfuric acid and hydrogen peroxide are 2.33 by volume ratio. Proportional mixing, adding nano-silicon particles into the mixture, the concentration of silicon nanoparticles in the mixed solution is 12.5 mg / mL, heating to 80° C. for magnetic stirring for 2 hours, centrifugal washing with water and vacuum drying to obtain modified silicon. The modified nano-silicon particles were dispersed in anhydrous ethanol, the concentration of silicon was 0.8 mg / mL, ultrasonic stirring was carried out for 1 h, a small amount of ammonia water was added dropwise, which was 0.4% of the volume of ethanol, and a certain amount of tetrafluoroethylene was added dropwise to it. Titanium isopropoxide, wherein the mass fraction of silicon nanoparticles relative...

Embodiment 2

[0038] 1) ultrasonically treat the graphite oxide filter cake with an average size of 150 μm in water, the ultrasonic frequency is 50 kHz, and the time is 1 h to prepare a graphene oxide dispersion liquid of 3 mg / mL; meanwhile, the concentrated sulfuric acid and hydrogen peroxide are 2.33 by volume ratio. Proportional mixing, adding nano-silicon particles into the mixture, the concentration of silicon nanoparticles in the mixed solution is 12.5 mg / mL, heating to 80° C. for magnetic stirring for 2 hours, centrifugal washing with water and vacuum drying to obtain modified silicon. Disperse the modified nano-silicon particles in ethanol, the concentration of silicon is 0.8mg / mL, ultrasonically stir for 1h, add a small amount of ammonia water, which is 0.4% of the volume of ethanol, and then add a certain amount of tetraisopropyl. Titanium alkoxide, wherein the mass fraction of silicon nanoparticles relative to titanium tetraisopropoxide is 200 mg / mL. The silicon-titanium dioxide ...

Embodiment 3

[0047] 1) ultrasonically treat the graphite oxide filter cake with an average size of 150 μm in water, the ultrasonic frequency is 50 kHz, and the time is 1 h to prepare a graphene oxide dispersion liquid of 3 mg / mL; meanwhile, the concentrated sulfuric acid and hydrogen peroxide are 2.33 by volume ratio. Proportional mixing, adding nano-silicon particles into the mixture, the concentration of silicon nanoparticles in the mixed solution is 12.5 mg / mL, heating to 80° C. for magnetic stirring for 2 hours, centrifugal washing with water and vacuum drying to obtain modified silicon. Disperse the modified nano-silicon particles in ethanol, the concentration of silicon is 0.8mg / mL, ultrasonically stir for 1h, add a small amount of ammonia water, which is 0.4% of the volume of ethanol, and then add a certain amount of tetraisopropyl. Titanium alkoxide, wherein the mass fraction of silicon nanoparticles relative to titanium tetraisopropoxide is 150 mg / mL. The silicon-titanium dioxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com