Zipper wire material and zipper tooth made of zipper wire material

A wire and zipper technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of high price of zipper wire, insufficient metal strength, poor oxidation resistance, etc., to improve metal strength and oxidation resistance, production Effects of cost reduction, good oxidation resistance and metal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

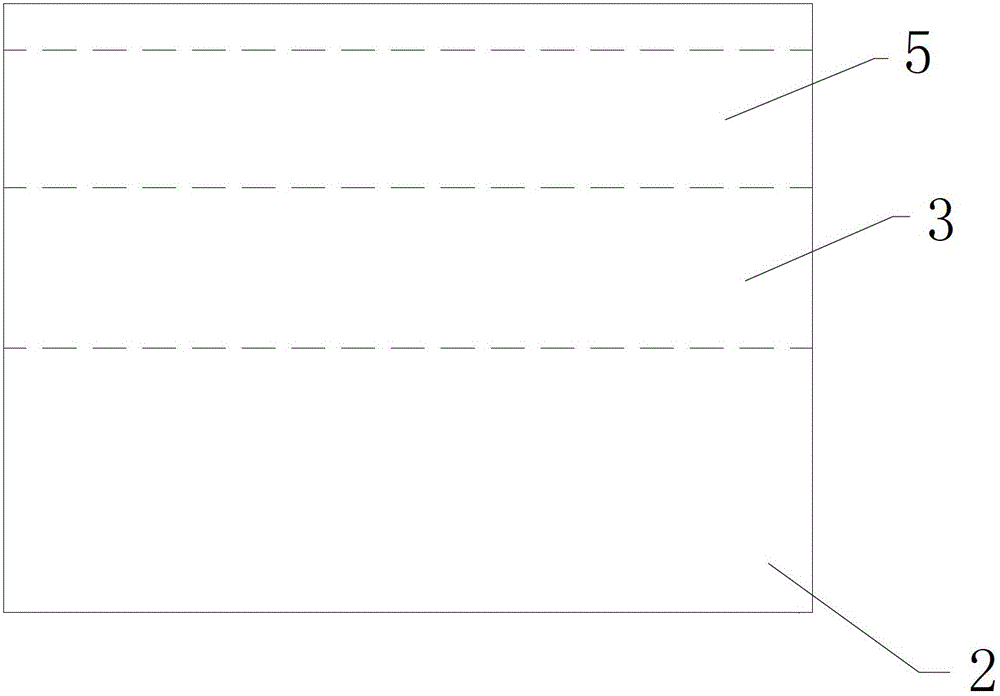

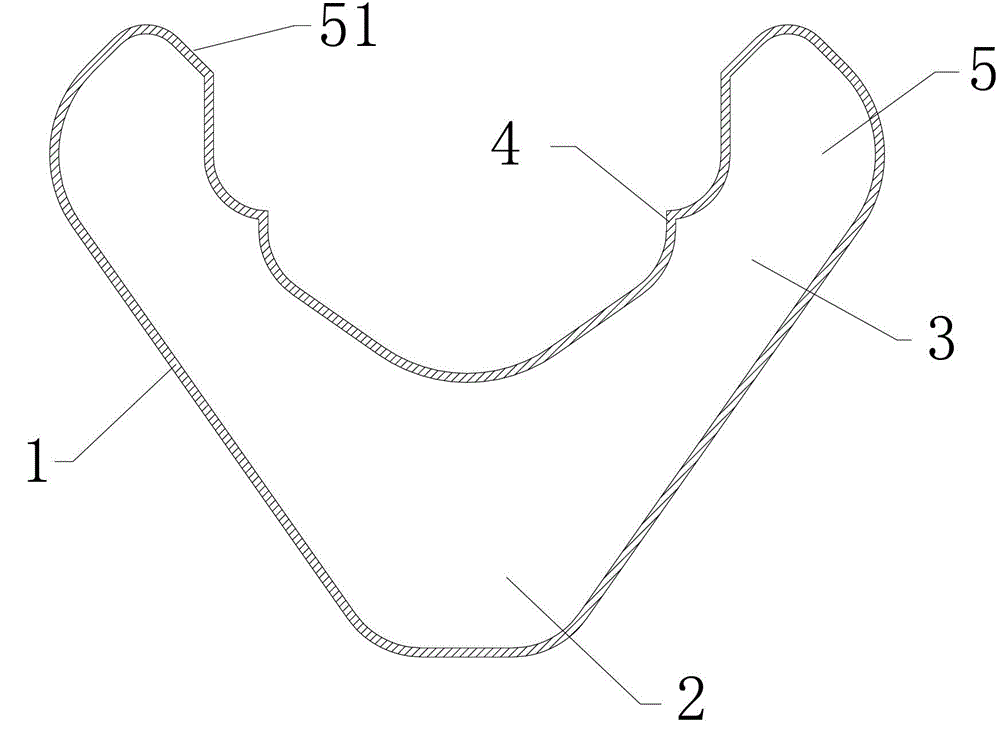

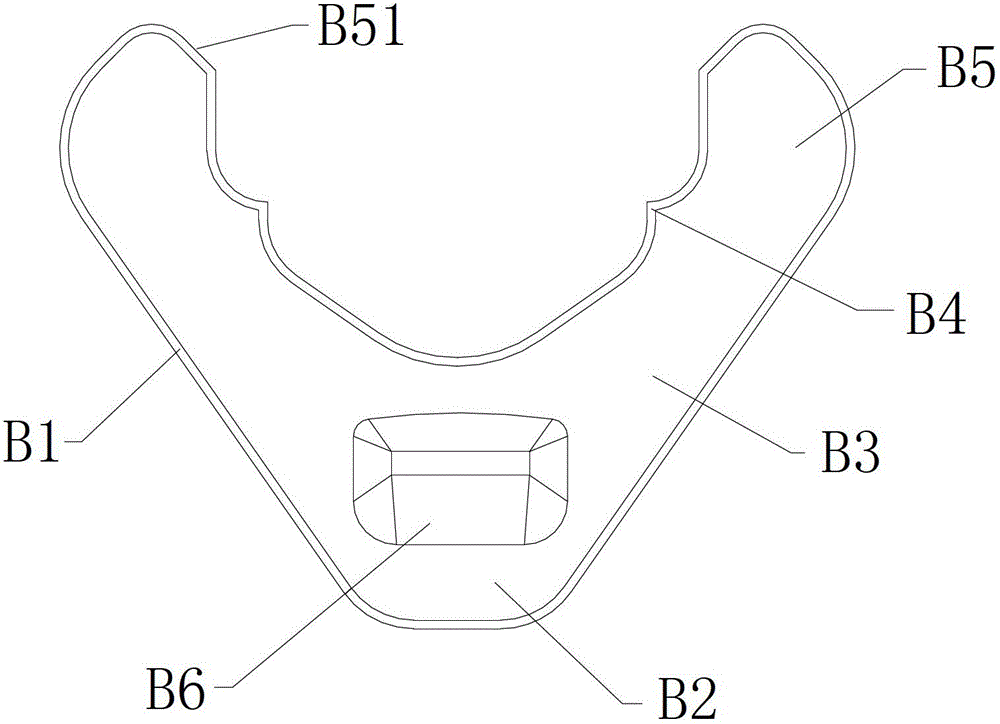

[0050] The first embodiment of the zipper wire of the present invention is as figure 1 with figure 2 As shown, it is linear, and its main body includes a head 2 and a pair of legs 3. In the cross section of the linear main body, the legs 3 are arranged on both sides of the main body and extend outward so that the two legs 3 are open. The legs 3 Including leg claws 5, leg claws 5 are arranged at the end of the legs 3, the main body is divided into an inner body and a wrapping layer 1, the inner body is covered and laminated with a wrapping layer 1 that strengthens the metal strength and oxidation resistance of the zipper wire, The cladding layer 1 is made of copper, and the inner body is made of aluminum alloy.

[0051] Because copper has good oxidation resistance and metal strength, the use of copper as the coating layer 1 of the zipper wire not only ensures the oxidation resistance of the zipper wire, but also ensures the metal strength of the zipper wire.

[0052] The pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com