Rotary drilling type sand-pumping hole-forming side wall high-pressure grouting device and construction method

A high-pressure grouting and hole-forming technology, used in excavation, infrastructure engineering, sheet pile walls, etc., can solve problems such as the inability to apply calcareous sand foundation, reduce friction between calcareous sand particles, and collapse of pile holes. , to achieve the effect of preventing collapse, saving materials and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

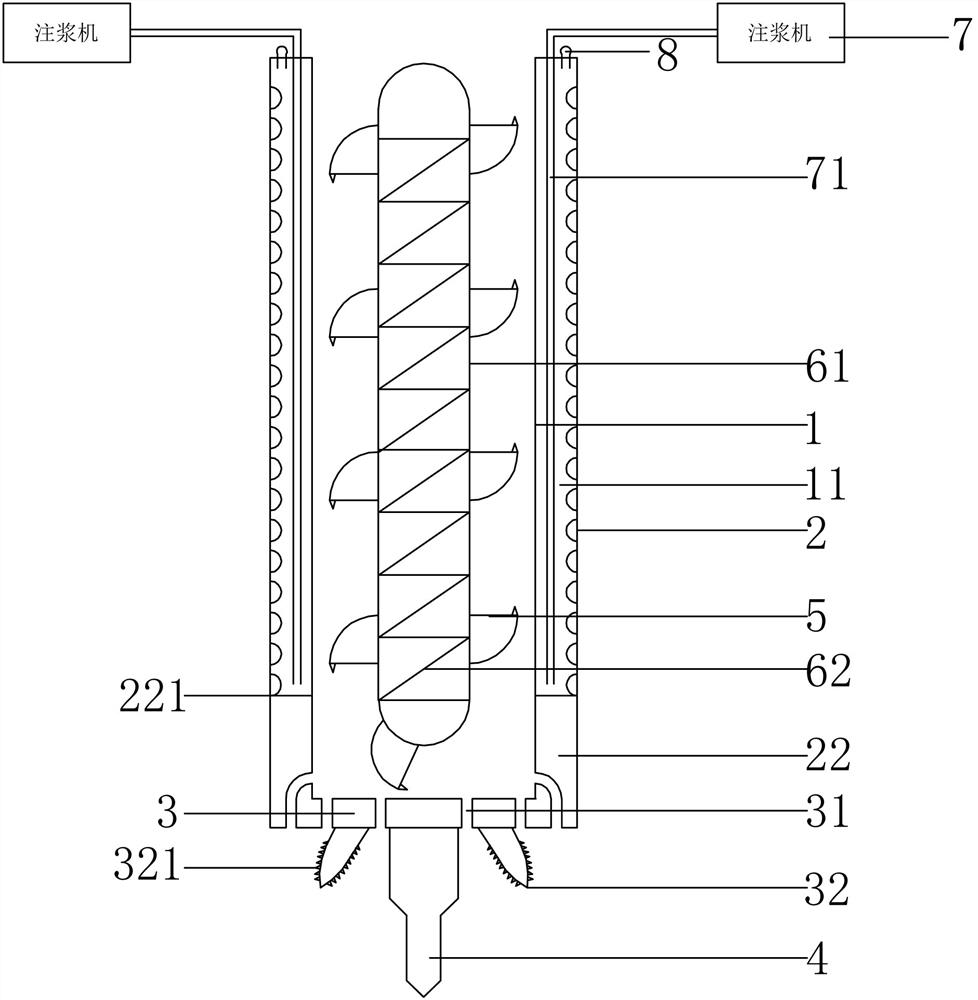

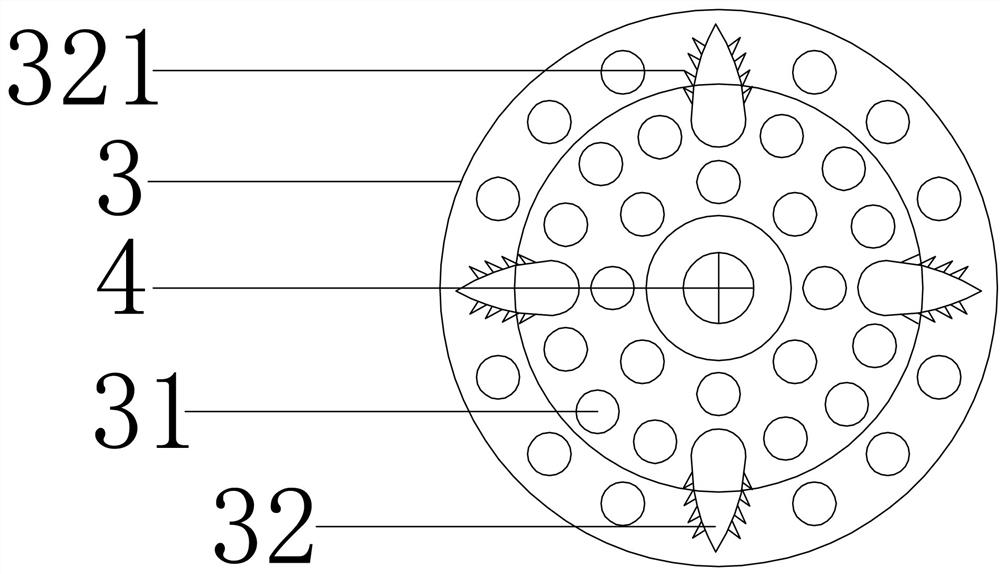

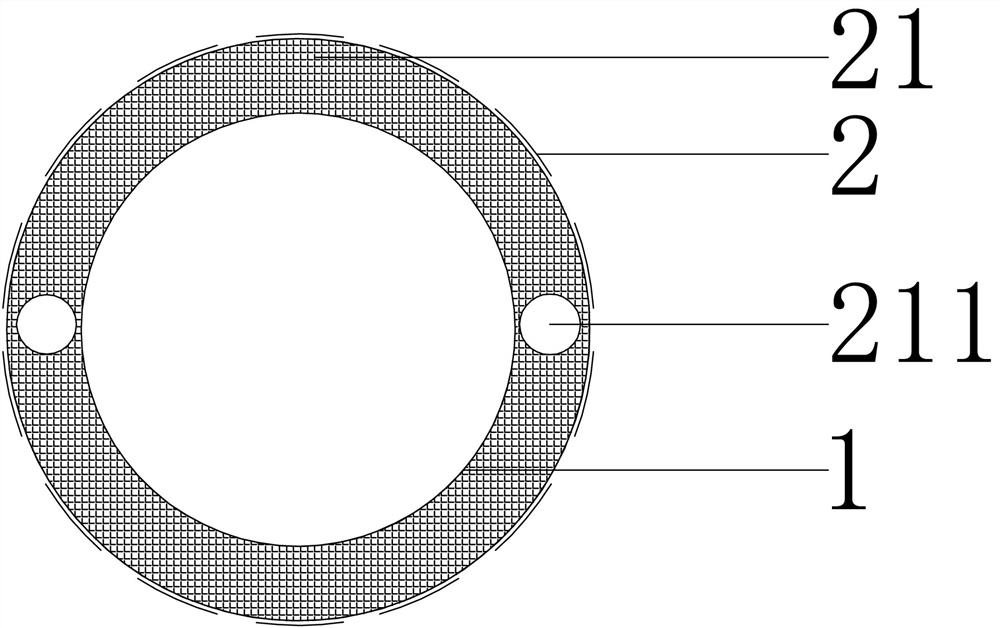

[0047] see Figure 1-4 , a rotary drilling-type sand pumping hole-forming side wall high-pressure grouting device, which includes an inner casing 1, the outside of the inner casing 1, and a length of casing on the upper part of which is wrapped with a flower tube 2, the inner casing 1 The outside of the casing 1, and the remaining length of the lower part is fixed with a steel casing 22. An annular cavity is formed between the inner casing 1 and the flower tube 2, and a slurry storage layer 11 is formed. The slurry storage layer 11 The opening at the top of the casing is blocked by a pressing sheet 21; the slurry storage layer 11 is connected to the grouting machine 7 for grouting; A chain bucket device 6 is arranged inside the inner casing 1 , and a plurality of evenly distributed buckets 5 for sand digging are arranged on the chain bucket device 6 . By adopting the high-pressure grouting device with the above-mentioned structure, the high-pressure grouting of the side wall ...

Embodiment 2

[0062] The method for constructing using any one of the rotary drilling type sand pumping hole-forming sidewall high-pressure grouting devices includes the following steps:

[0063] S1: Level the construction area and remove debris, make uniform arrangements for the mud pool, suction machine, grouting machine and construction access road in the construction area to facilitate construction, survey the average particle size of calcareous sand at different depths in the area, Add expansion agent, accelerator and additives to prepare modified slurry with suitable water-cement ratio;

[0064] S2: Determine the size and depth of the piling hole. According to the average particle size of the calcareous sand under the foundation measured before construction, select the pumping pan 3 of the appropriate size suction hole 31 and place it on the front end of the device, and splice the steel frame 62 inside the device with the excavation. bucket 5, and make its length suitable for the dept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com