Converter bottom structure with multi-point rider brick deploying and controlling and building method of converter bottom structure

A converter bottom and brick locking technology, which is applied in the manufacture of converters, etc., can solve problems such as loose bottom and poor mechanical stability of the bottom of the furnace, and achieve the effects of uniform thermal stress release, simple construction, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Example: In the third branch of WISCO Steelmaking Plant, June 1, 2008, the 250-ton top-bottom composite oxygen converting converter was overhauled and built on October 2, 2008. The 250-ton top-bottom composite oxygen converting converter was overhauled. During the construction process, the applicant adopted the converter bottom structure with multi-point deployment control and lock bricks of the present invention, and formulated strict technical procedures and quality control specifications, and achieved complete success.

[0042] The concrete masonry method is as follows:

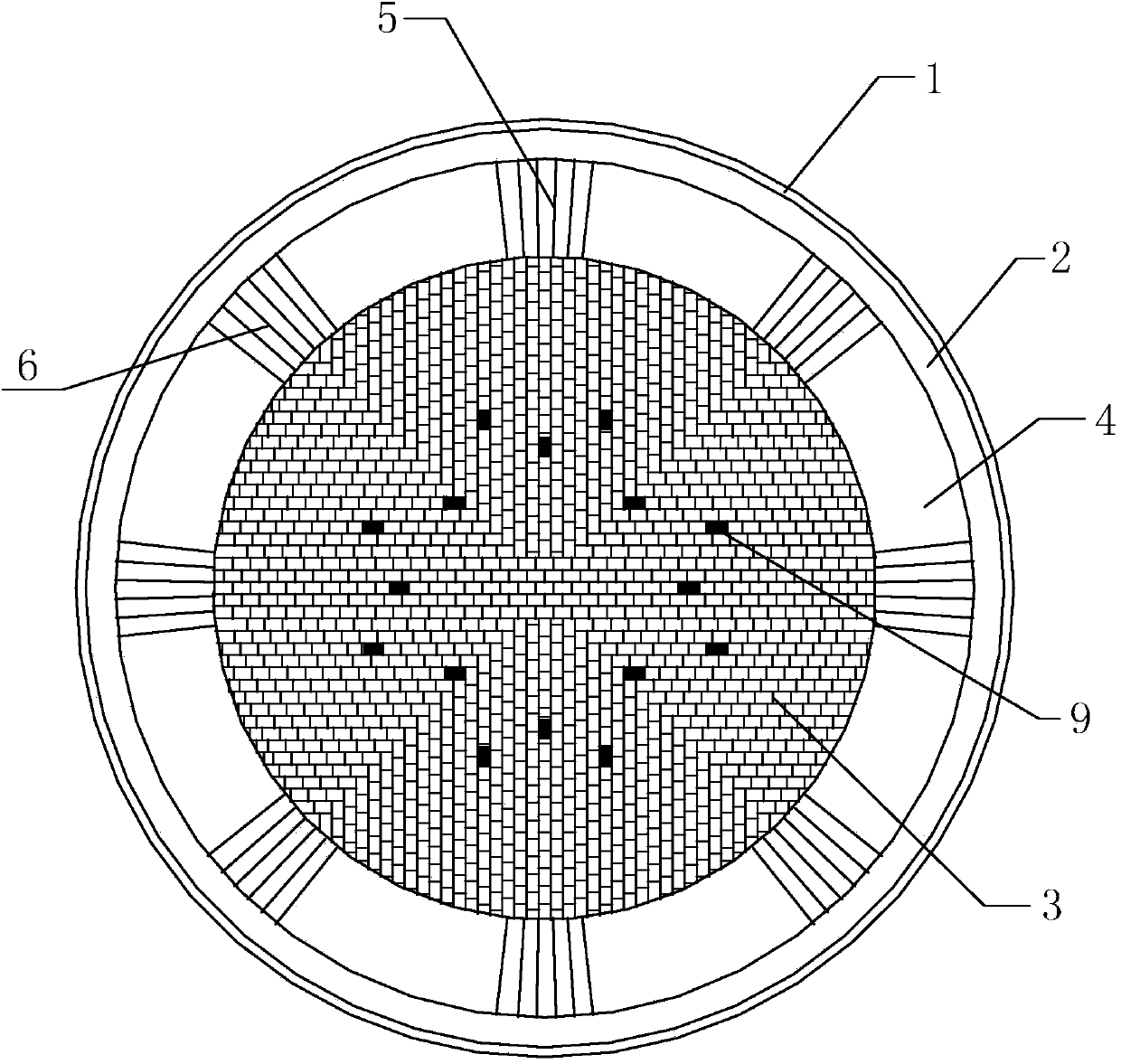

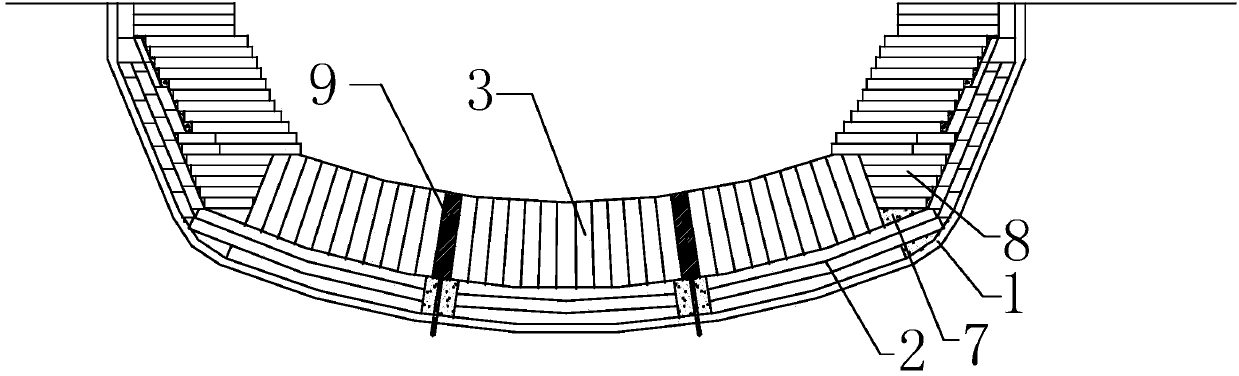

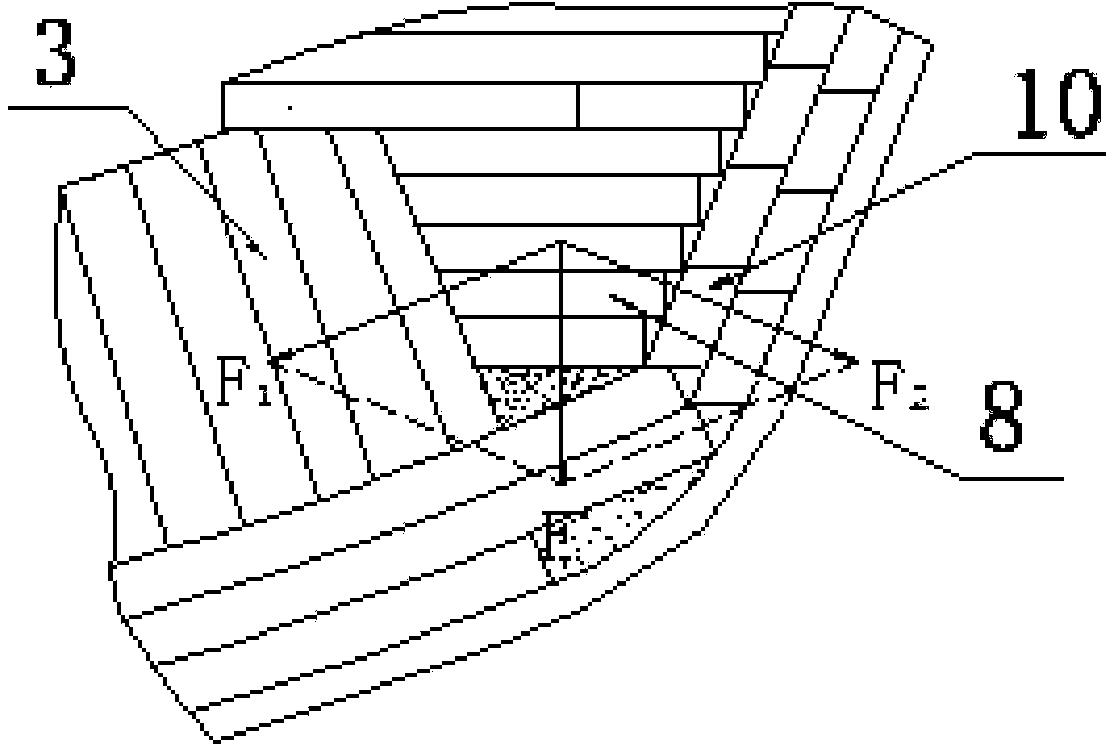

[0043] (1) Masonry of permanent layer of furnace bottom: Before the permanent layer of furnace bottom is built, the furnace must be cleaned. The opening of the gas supply pipe to the furnace bottom shell at the position of the ventilating brick required by the steelmaking process is used as the reference. Cross line, divide the furnace body into four equal parts, and draw four vertical control lines on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com