Magnetic coupling performance testing device

A technology of magnetic coupling and testing device, which is applied in the direction of measuring device, testing of machine/structural components, testing of mechanical components, etc. Local overheating, uniform thermal expansion and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

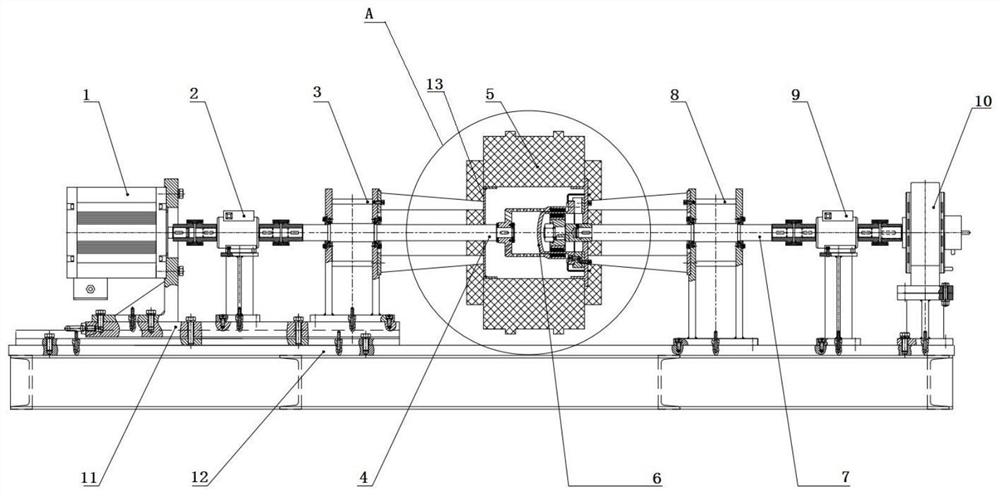

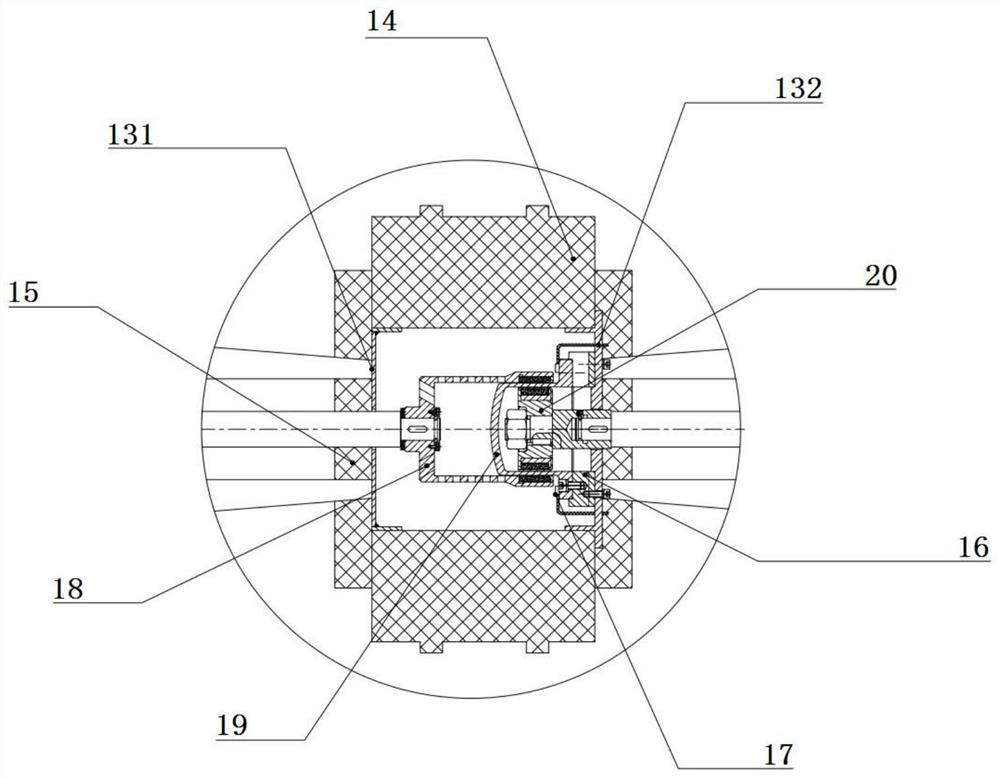

[0019] Such as figure 1 As shown, a magnetic coupling performance test device, the magnetic coupling test device is divided into two parts, the input end and the output end, mainly including the motor 1, the input end speed torque sensor 2, the input end bearing assembly 3, the input shaft 4. High temperature test chamber 5, coupling test piece 6, output shaft 7, output end bearing assembly 8, output end speed torque sensor 9, brake 10, slide rail 11 and base 12. Such as figure 2 The distance shown, the coupling test piece 6 is set in the high temperature test chamber 5 which is hollow inside, the left and right ends of the coupling test piece 6 are respectively connected with the input shaft 4 and the output shaft 7, and the two side walls of the high temperature test chamber 5 are respectively set There is a flange bracket 13 for fixing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com