High-pressure module for supercritical 350MW three-cylinder steam turbine

A high-pressure module and steam turbine technology, which is applied in mechanical equipment, engine components, combined engines, etc., can solve the problems of uneven thermal expansion of faceted flanges, inconvenient on-site installation, and complicated steam inlet structure, and achieves the advantages of quick start, Easy on-site installation, improved sealing and thermal expansion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

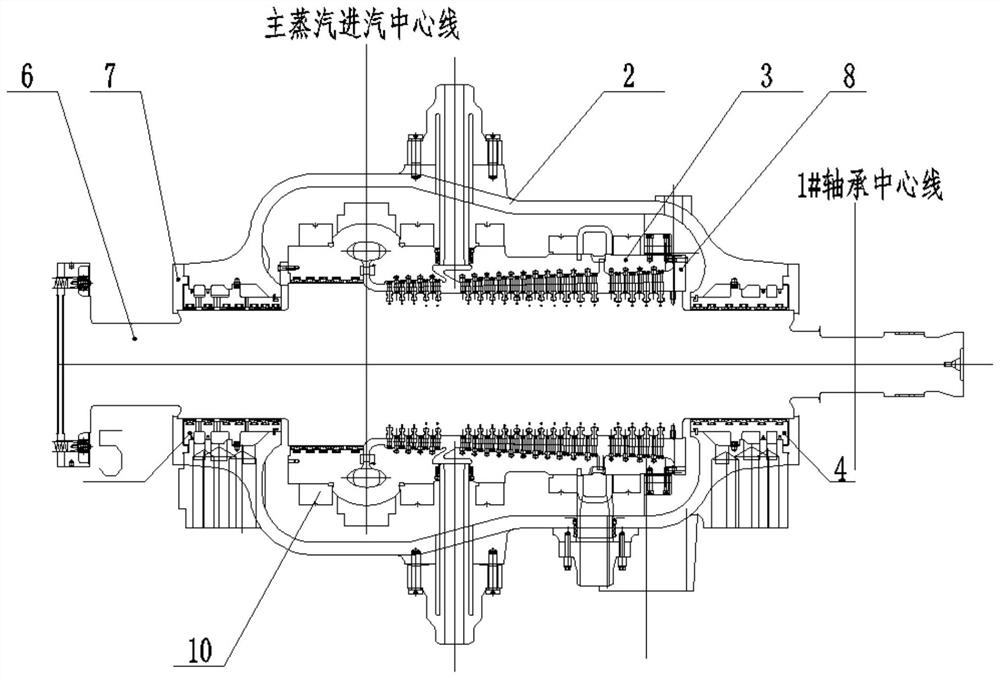

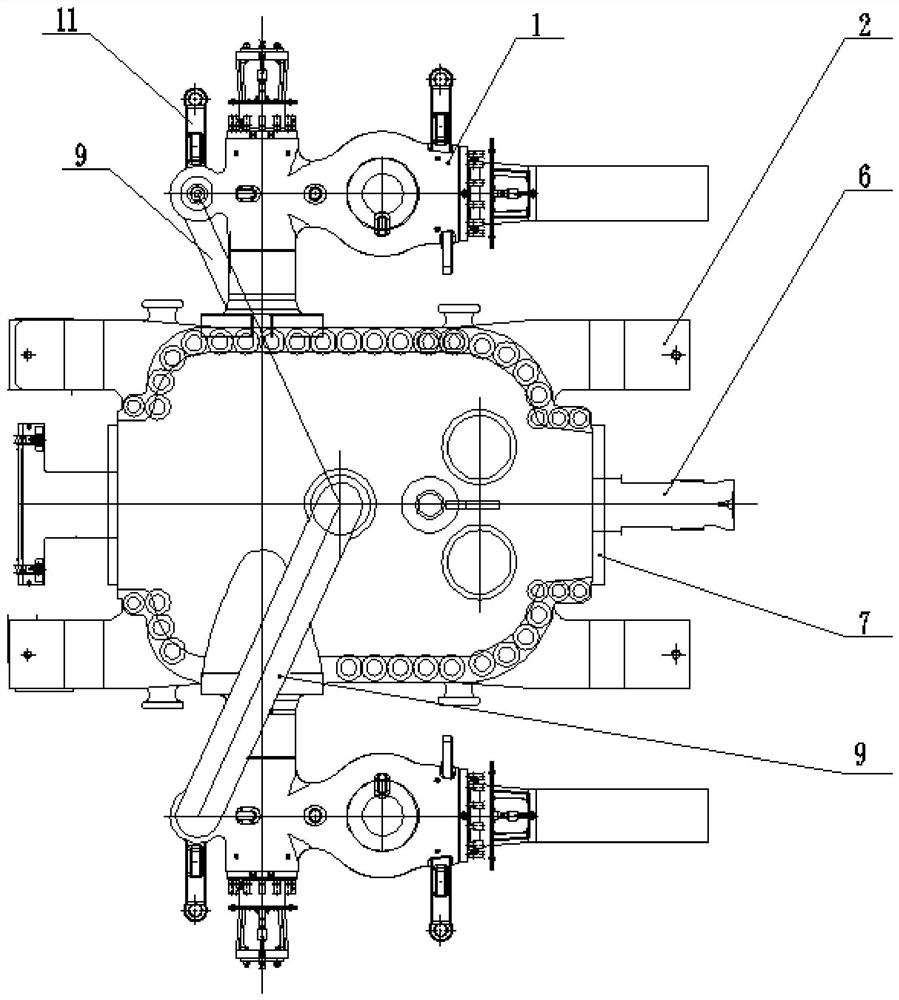

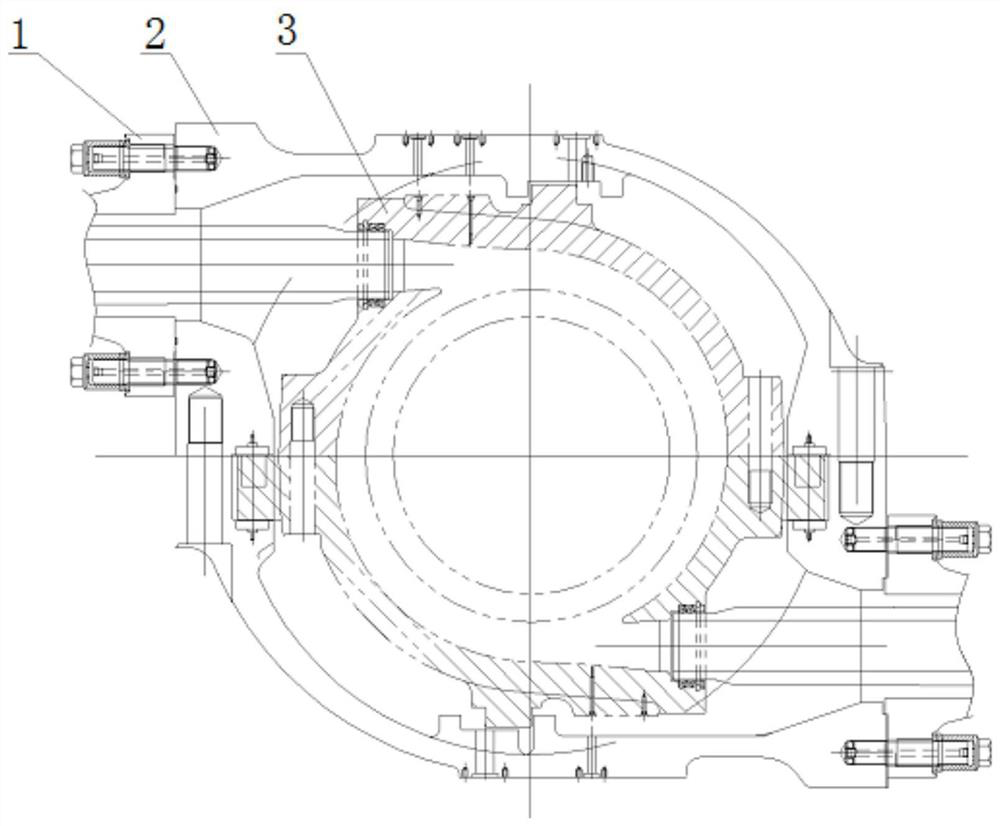

[0020] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a high-pressure module for a supercritical 350MW three-cylinder steam turbine in this embodiment, it includes two high-pressure main steam regulating combined valves 1, it also includes a high-pressure outer cylinder 2, a high-pressure inner cylinder 3, a high-pressure cylinder Adjustment end steam seal 4, high pressure cylinder electric end steam seal 5, high pressure rotor 6, high pressure outer cylinder positioning plate 7, high pressure inner cylinder positioning plate 8, two supplementary steam conduits 9, multiple red collars 10 and two high pressure supplementary The steam valve 11, two high-pressure main steam regulating combined valves 1 and the high-pressure outer cylinder 2 are directly connected by flanges, the high-pressure inner cylinder 3 is installed in the high-pressure outer cylinder 2, and a plurality of red collars 10 are set on the high-pressure inner cylinder 3...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 1 to Figure 3 To describe this embodiment, the stationary blades and moving blades in the high-pressure outer cylinder 2 of this embodiment both adopt a pre-twisted assembled structure. In this way, the assembled structure has no welds, avoids welding deformation, and better ensures the flow accuracy. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 1 to Figure 3 To illustrate this embodiment, the high-pressure inner cylinder 3 and the high-pressure rotor 6 of this embodiment are connected by multi-stage small enthalpy drop reaction blades, and the stator blades of the high-pressure inner cylinder and the high-pressure rotor moving blades are arranged alternately to form 20 stages of small enthalpy drop reaction flow through. With such setting, the energy loss is small and the efficiency is high. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com