Adjustable strip-plating die

A mold and bar adjustment technology, which is applied in the field of adjustable bar plating molds, can solve the problems of large deformation of the screw rod, inaccurate relative position, large deformation, etc., and achieve the effect of increased rigidity, improved precision and good rigidity of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

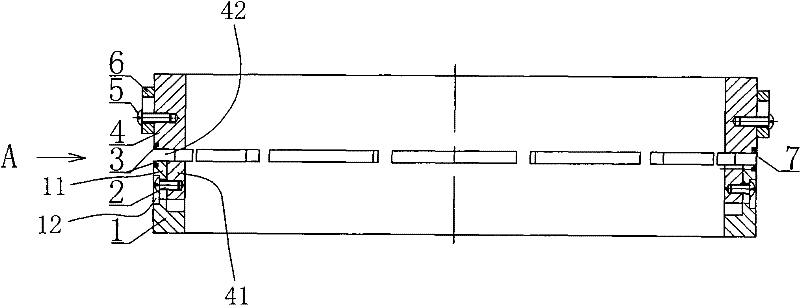

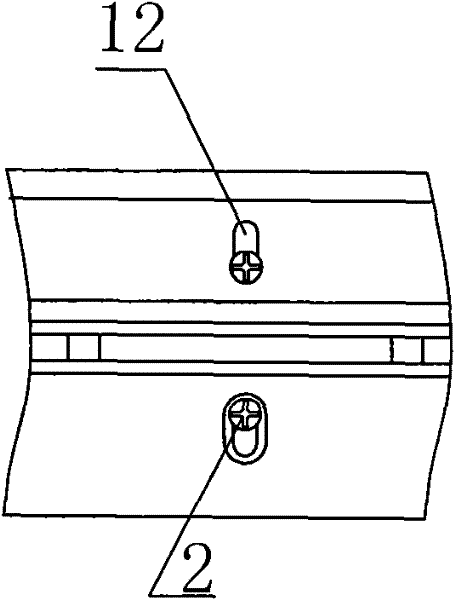

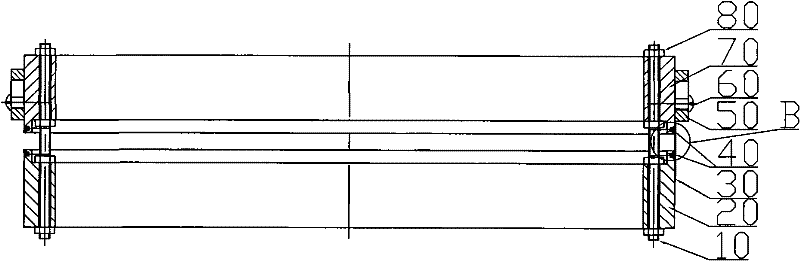

[0019] See figure 1 with figure 2 , figure 1 with figure 2 Disclosed is an adjustable strip plating mold, including a ring-shaped upper mold 4 and a ring-shaped lower mold 1 with the same diameter as the ring-shaped upper mold 4, and the ring-shaped upper mold 4 and the ring-shaped lower mold 1 A convex ring 41 is provided on the side in contact with the convex ring 41, a circle of water passing holes 42 is provided on the convex ring 41, and a threaded hole 43 is provided on the outside of the water passing hole 42. The ring-shaped upper mold 4 is provided with a concave ring 11 on the contact side. The ring-shaped lower mold 1 is provided with an axially elongated adjusting hole 12 relative to the threaded hole 43. The ring-shaped upper mold 4 The ring-shaped lower mold 1 is sleeved in a transitional fit through the convex ring 41 and the concave ring 11, and the screw 2 is screwed into the threaded hole 43 through the elongated adjusting hole 12, and the ring-shaped low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com