A kind of cold-resistant insulating resin composition and preparation method thereof

A technology of insulating resin and composition, which is applied in the field of cold-resistant insulating resin composition and its preparation, which can solve the problems of cold resistance and poor mechanical properties, and achieve the effects of water vapor resistance, improved rebound performance, and excellent low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

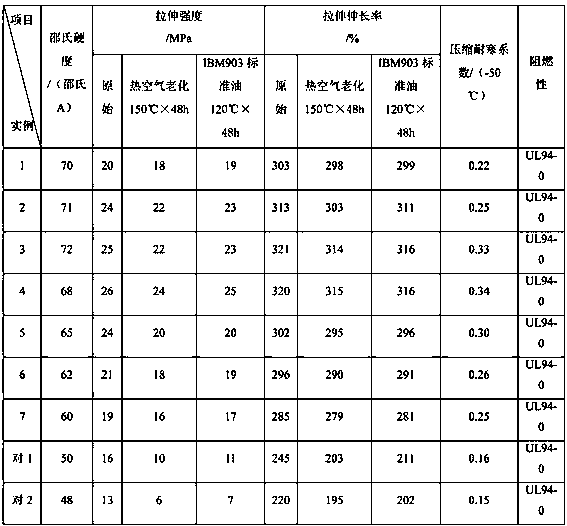

Examples

Embodiment 1

[0026] A cold-resistant insulating resin composition, made of the following raw materials in parts by weight:

[0027] German Lanxess EPT6850 EPDM rubber (53% ethylene mass fraction) 70 parts, low cis-butadiene rubber 10 parts, styrene-butadiene rubber 22 parts, wood fiber 5 parts, flame retardant 5 parts, filler 80 parts, anti-aging 3 parts of curing agent, 4 parts of vulcanizing agent, 1 part of crosslinking agent, 12 parts of softener and 4 parts of accelerator.

[0028] The flame retardant is antimony trioxide.

[0029] The filler is carbon black N550.

[0030] The anti-aging agent is MB and 4010NA, and the weight ratio of the two is 0.5:1.

[0031] Described vulcanizing agent is dicumyl peroxide.

[0032] The crosslinking agent is N-N m-phenylene bismaleimide.

[0033] Described softening agent is hydroxyl silicone oil.

[0034] Described accelerator is magnesium oxide and stearic acid, both weight ratios are 2:1.

[0035] The preparation method of above-mentioned c...

Embodiment 2

[0040] A cold-resistant insulating resin composition, made of the following raw materials in parts by weight:

[0041] 72 parts of German Lanxess EPT6650 EPDM rubber (53% by mass of ethylene), 12 parts of low cis-butadiene rubber, 24 parts of styrene-butadiene rubber, 6 parts of wood fiber, 6 parts of flame retardant, 85 parts of filler, anti-aging 4 parts of curing agent, 4.5 parts of vulcanizing agent, 1 part of crosslinking agent, 15 parts of softener and 5 parts of accelerator.

[0042] The flame retardant is molybdenum dioxide.

[0043] The filler is carbon black N220.

[0044] The anti-aging agent is MB and 4010NA, and the weight ratio of the two is 0.8:1.

[0045] Described vulcanizing agent is dicumyl peroxide.

[0046] The crosslinking agent is triallyl isocyanurate.

[0047] Described softening agent is naphthenic oil.

[0048] Described accelerator is magnesium oxide and stearic acid, both weight ratios are 3:1.

[0049] The preparation method of above-mentioned...

Embodiment 3

[0054] A cold-resistant insulating resin composition, made of the following raw materials in parts by weight:

[0055] 78 parts of German Lanxess EPT6850 EPDM rubber (53% by mass of ethylene), 15 parts of low cis-butadiene rubber, 25 parts of styrene-butadiene rubber, 8 parts of wood fiber, 6.5 parts of flame retardant, 90 parts of filler, anti-aging 5 parts of curing agent, 5 parts of vulcanizing agent, 1.1 parts of crosslinking agent, 18 parts of softener and 6 parts of accelerator.

[0056] The flame retardant is antimony trioxide and calcium carbonate, and the weight ratio of the two is 1:1.

[0057] The fillers are carbon black N550 and carbon black N330 with a weight ratio of 1:1.

[0058] The anti-aging agent is MB and 4010NA, and the weight ratio of the two is 1:1.

[0059] Described vulcanizing agent is dicumyl peroxide.

[0060] The crosslinking agent is N-N m-phenylene bismaleimide and triallyl isocyanate, and the weight ratio of the two is 1:1.

[0061] Describ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com