Offline preheating device for hot mill rollers

A technology of preheating device and hot rolling mill, which is applied in the direction of rolling, metal rolling, metal rolling, etc., can solve the unfavorable surface control of hot rolled titanium plate, affect the rolling surface quality of finished titanium plate, and semi-finished rolling Poor effect of preheating rolls and other problems, to avoid the problem of uneven thermal expansion, to facilitate the control of rolling strip shape, and to achieve the effect of excellent rolling strip shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

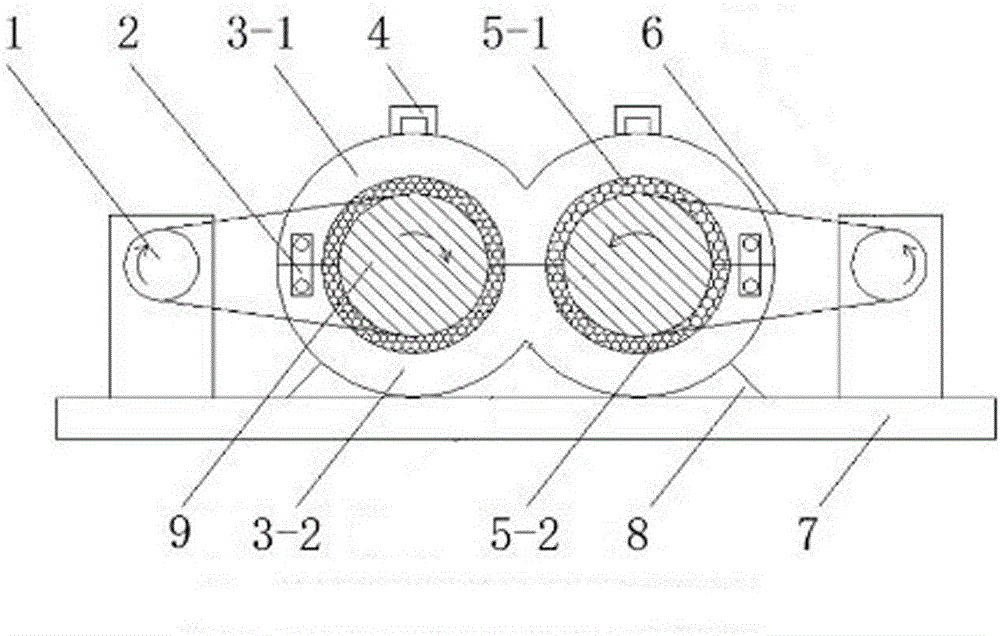

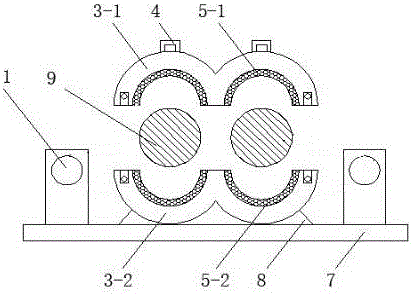

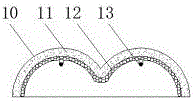

[0024] Embodiment 1: As shown in the figure, an off-line preheating device for rolls of a hot rolling mill is composed of a heating furnace, a power device 1 and a base 7, and the power device 1 is two motors, which are fixedly arranged on the base 7 opposite to each other. A heating furnace is set between the two motors at both ends of the motor. The heating furnace is in the shape of a gourd or 8 placed horizontally. The body 3-2 is fixedly welded on the base 7 through the reinforcing rib 8, the upper half furnace body 3-1 is provided with hoisting lugs 4, and the end faces of the upper half furnace body 3-1 and the lower half furnace body 3-2 A locking device 2 is provided at the junction, an upper heating layer is provided on the inner wall of the upper half furnace body 3-1, and a lower heating layer is provided on the inner wall of the lower half furnace body 3-2. The furnace body structure of the upper half furnace body 3-1 From the inside to the outside are the upper h...

Embodiment 2

[0029] Embodiment 2: On the basis of embodiment 1, the distance between the roll body of the roll 9 installed in the heating chamber and the heating layer 12 is 100 mm, and the distance between the end face of the roll body of the roll 9 and the end face of the chamber where the roll 9 is located The distance is 50mm, and the distance between the thermocouple 13 temperature measuring point and the insulation layer 11 is 60mm.

Embodiment 3

[0030] Embodiment 3: On the basis of embodiment 1, the distance between the roll body 9 installed in the heating chamber and the heating layer 12 is 200mm, and the distance between the end face of the roll body 9 and the end face of the chamber where the roll 9 is located The distance is 150mm, and the distance between the thermocouple 13 temperature measuring point and the insulation layer 11 is 40mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com