Liquid-cooled crystallizer for continaous casting of metals

A crystallizer and crystallizer plate technology, applied in the field of liquid-cooled crystallizers, can solve problems such as small static friction of elastic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

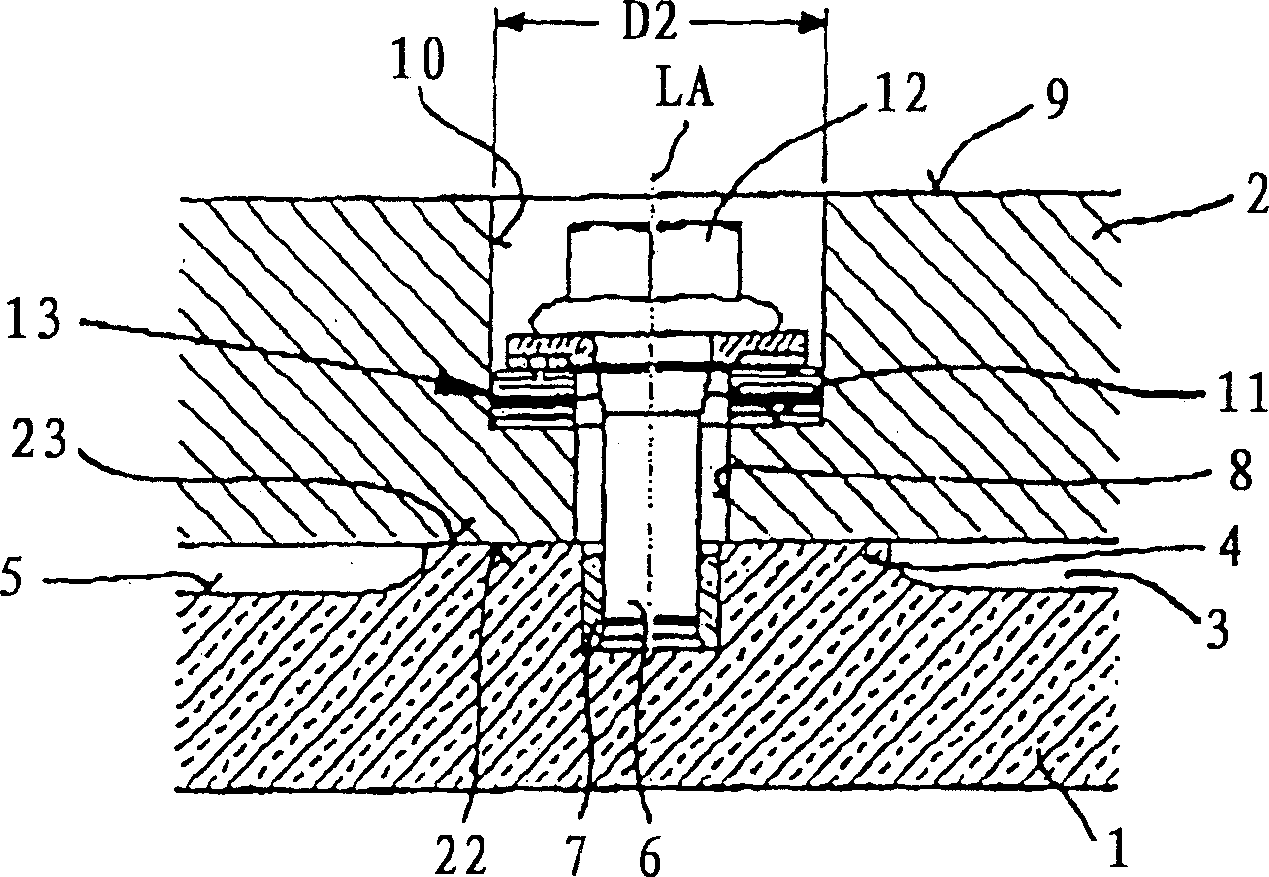

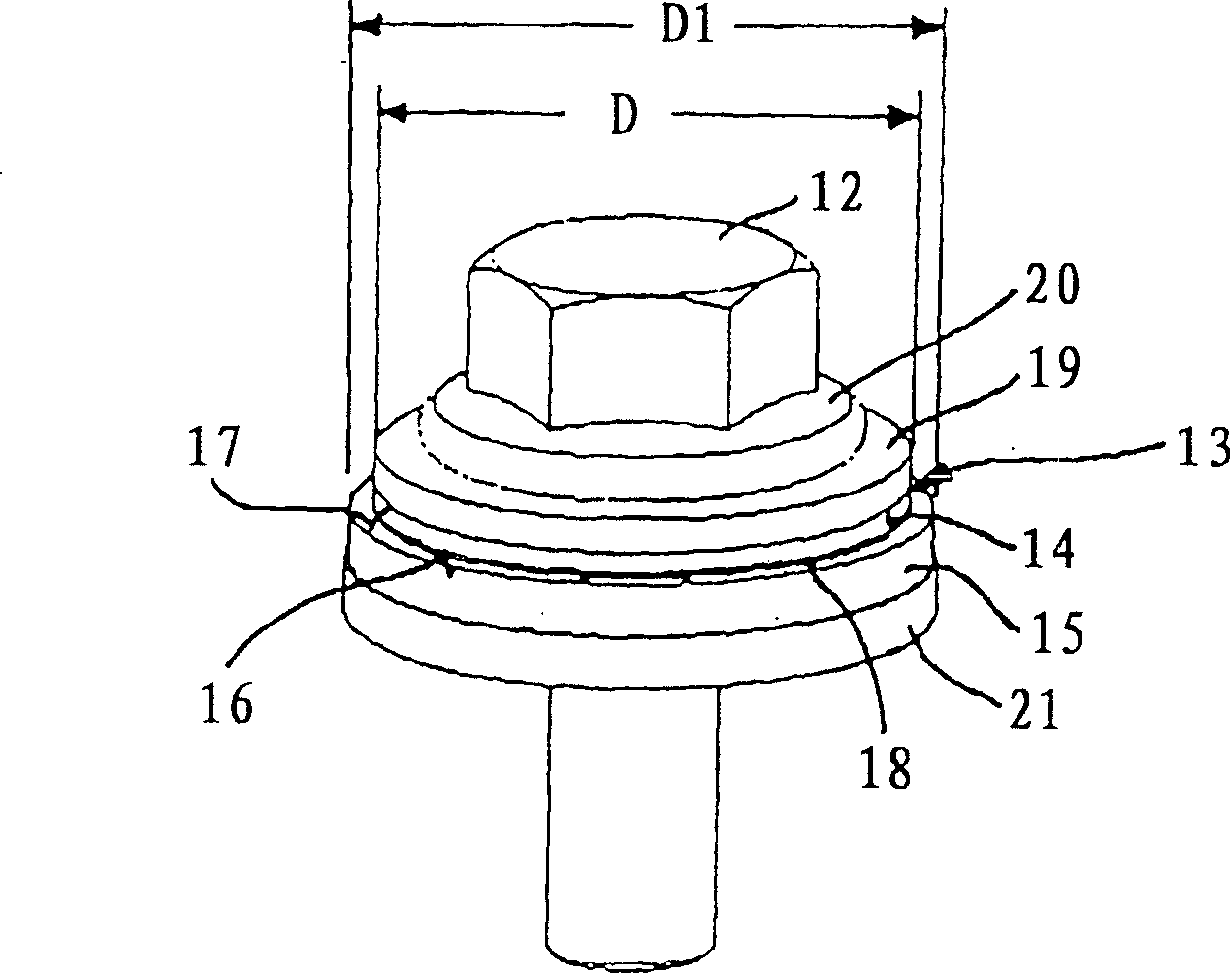

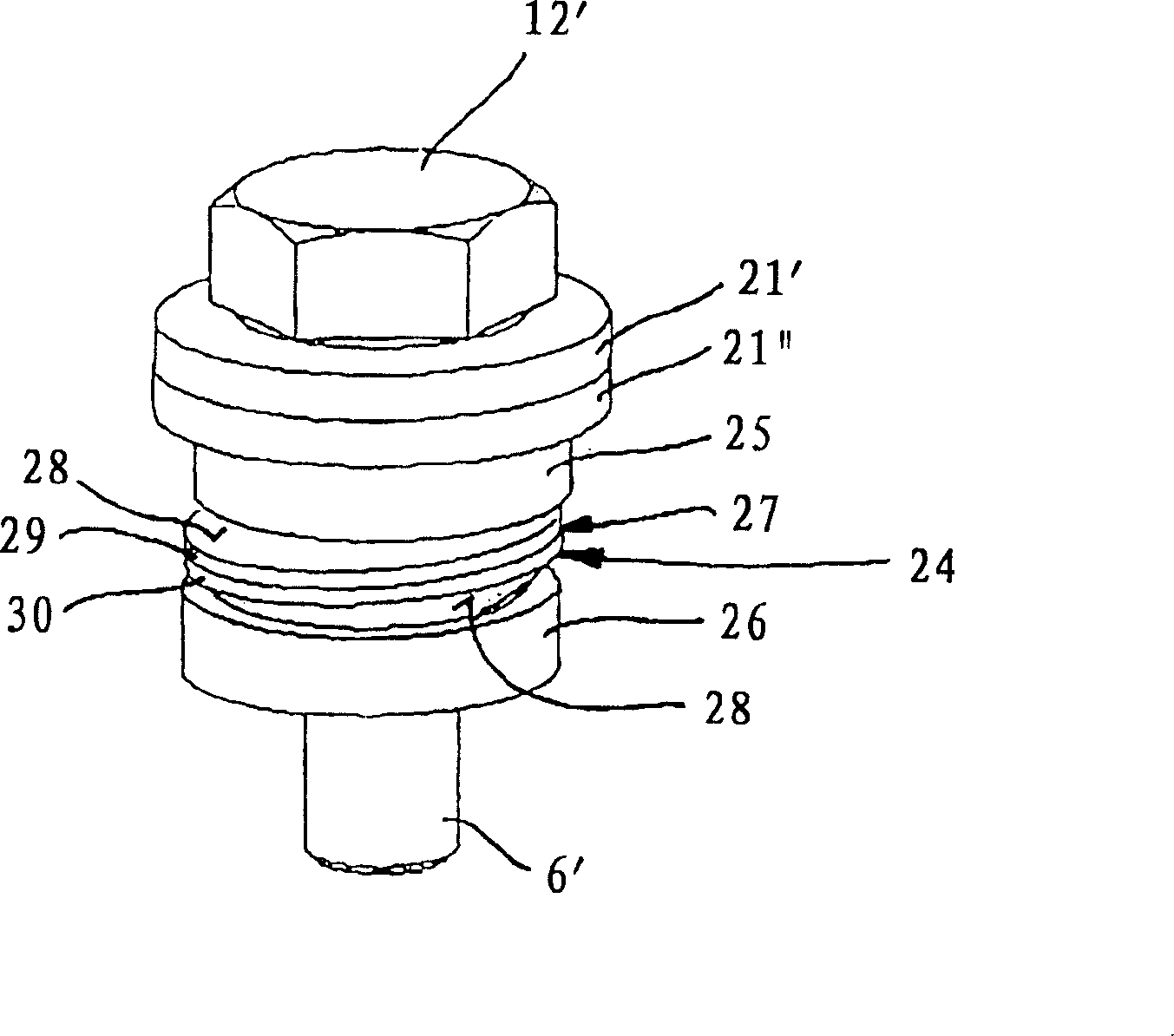

[0022] figure 1 shows a cross-section of the connection area of a mold plate 1 made of copper or a copper alloy, which is fastened on the rear side to a carrier plate 2 . The carrier plate 2 can not only be an adapter plate but also be a component of a water tank not further shown in the figures.

[0023] In the present exemplary embodiment, a cooling gap 3 through which a coolant flows is formed between the mold plate 1 and the support plate 2 . It extends between platforms 4 arranged at a distance from one another, which themselves protrude island-like from the coolant side 5 of the mold plate 1 . In the platform 4 shown in the figure, a bolt 6 is screwed into the center. The bolt 6 engages in a threaded bush 7 in the platform 4 . The bolts 6 pass with play through the through-holes 8 in the carrier plate 2 . The through-hole 8 widens in diameter in the direction of the rear side 9 of the carrier plate 2 into a cylindrical down-hole 10 . In the radially extending hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com