A long-life and durable lead-antimony alloy high-grade antimony white volatilization furnace

An antimony alloy, long-life technology, applied in the field of long-life durable lead-antimony alloy high-grade antimony white volatilization furnace, can solve the problems of uneven heating, thermal stress concentration, furnace bottom deformation, etc., achieve simple design, uniform thermal stress distribution, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

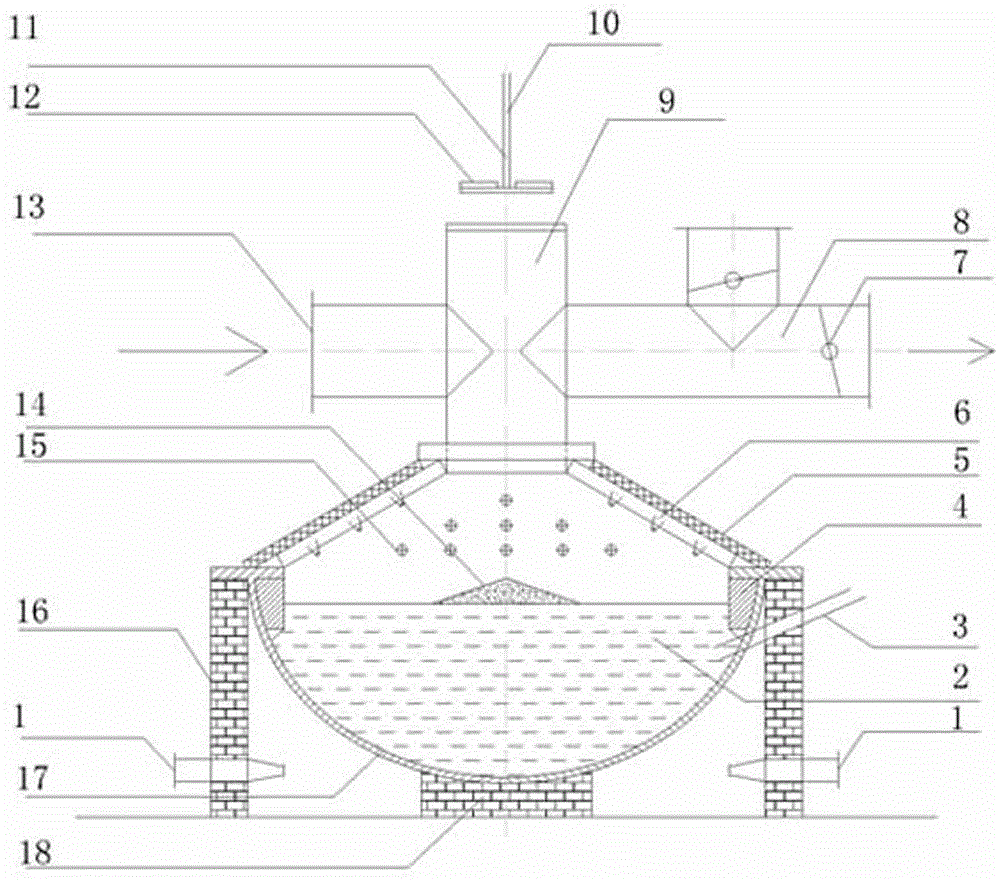

[0019] Such as figure 1 As shown, an embodiment of the long-life and durable lead-antimony alloy high-grade antimony white volatilization furnace of the present invention includes a furnace body 17, which is a hemispherical pot body set up through a furnace body wall 16 and a furnace bottom base 18. The furnace body The wall 16 is provided with a flame nozzle 1 facing the bottom of the furnace body 17 and a feed port 3 connected to the inner cavity of the furnace body 17, and a layer of high-temperature refractory material layer 4 with strong corrosion resistance is embedded near the slag line of the furnace body 17. . The top of the body of furnace 17 is covered with a gas collecting hood 5, which is conically upside-down and arranged on the body of furnace 17, and the gas collecting hood 5 is provided with a plurality of primary inlets that are inclined to the liquid surface of the furnace body. Gas nozzle 6, and the central part of the gas collecting hood 5 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com