Processing method of glass substrate

A technology for glass substrates and processing methods, applied in metal processing equipment, manufacturing tools, grinding devices, etc., can solve problems such as glass strength not meeting requirements, and achieve the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The glass obtained by the processing method of the glass substrate provided by the present invention is applied to consumer electronic products as a protective cover or backplane, for example, the glass substrate can be used as a cover or backplane of a smart phone.

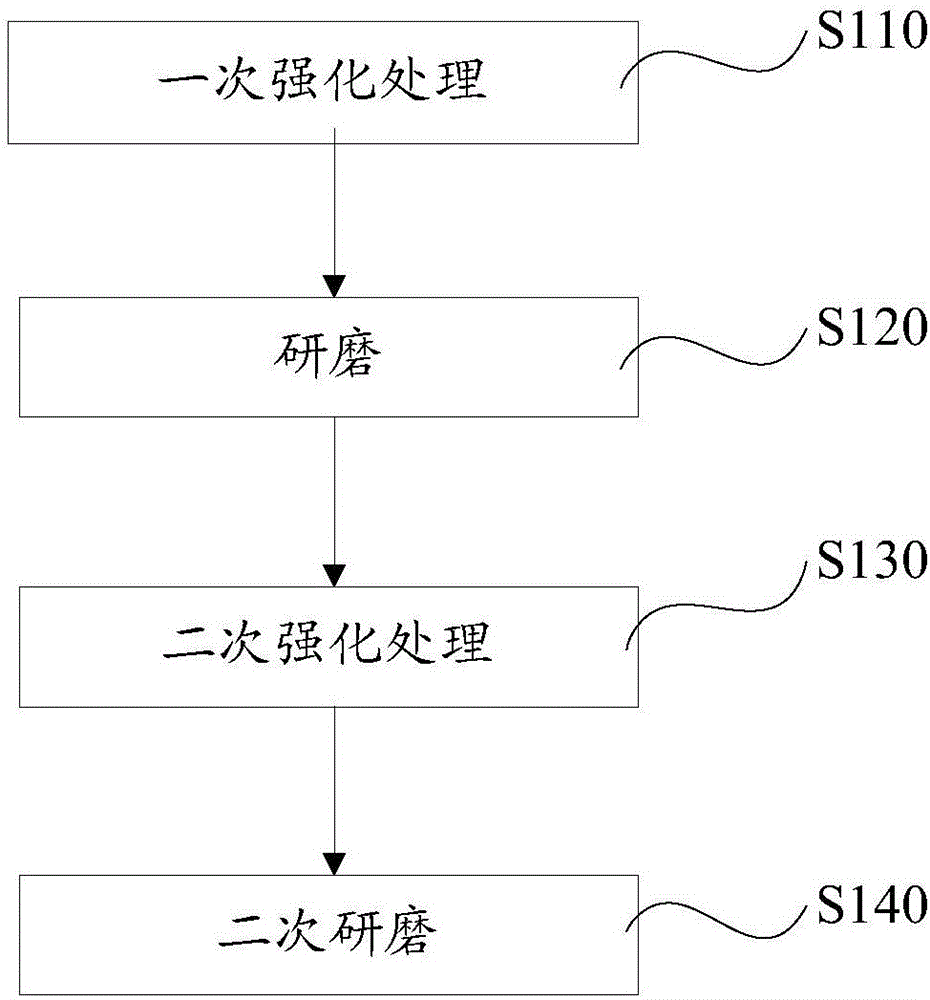

[0020] Such as figure 1 As shown, in one embodiment, the glass substrate processing method provided by the present invention includes sequentially performing step S110: primary strengthening treatment; step S120: grinding; and step S130: secondary strengthening treatment on the provided glass substrate.

[0021] The glass substrate provided by the present invention refers to silicate glass containing alkali metal ions, such as lithium ions or sodium ions. The glass substrate has opposing first and second surfaces. The glass substrate also has side surfaces connecting the first surface and the second surface. Suitable for the development trend of light and thin consumer electronic products, the thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com