Detection device for detecting macro-defects in infrared glass

A technology for infrared glass and macroscopic defects, which is applied in the direction of optical testing for flaws/defects, etc., can solve problems such as inconvenient operation, lack of infrared glass detection devices, complex devices, etc., and achieve strong adaptability to thickness and dimension changes, fast and convenient operation, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

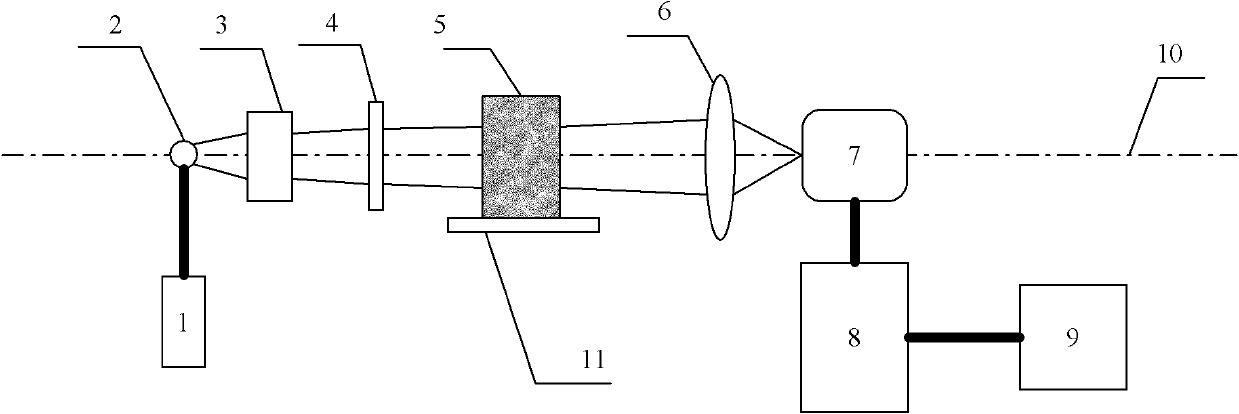

[0019] An infrared glass internal macroscopic defect detection device, comprising an adjustable power supply 1, an infrared light source 2, a round tube 3, an infrared-transmitting flat frosted glass 4, an infrared lens 6, an infrared area array imaging detector 7, an image processing module 8 and a display 9, Infrared light source 2, circular tube 3, infrared-transmitting flat glass 4, infrared lens 6 and infrared area array imaging detector 7 are arranged in sequence, and the infrared glass sample 5 to be tested is placed between the infrared-transmitting flat glass 4 and the infrared lens 6. The inner wall of the tube 2 is black, and the inner wall of the round tube 2 is provided with threads that can eliminate stray light. The inner diameter of the round tube 3 is and the diameter of the measured infrared glass sample 5 The ratio is ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com