Numerical control particle glass cutting machine

A glass cutting and cutting machine technology, applied in the direction of glass cutting devices, glass production, glass manufacturing equipment, etc., can solve the problems of low production efficiency, affecting production efficiency, and not too much impact, so as to achieve improved production efficiency and significant production efficiency , Good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

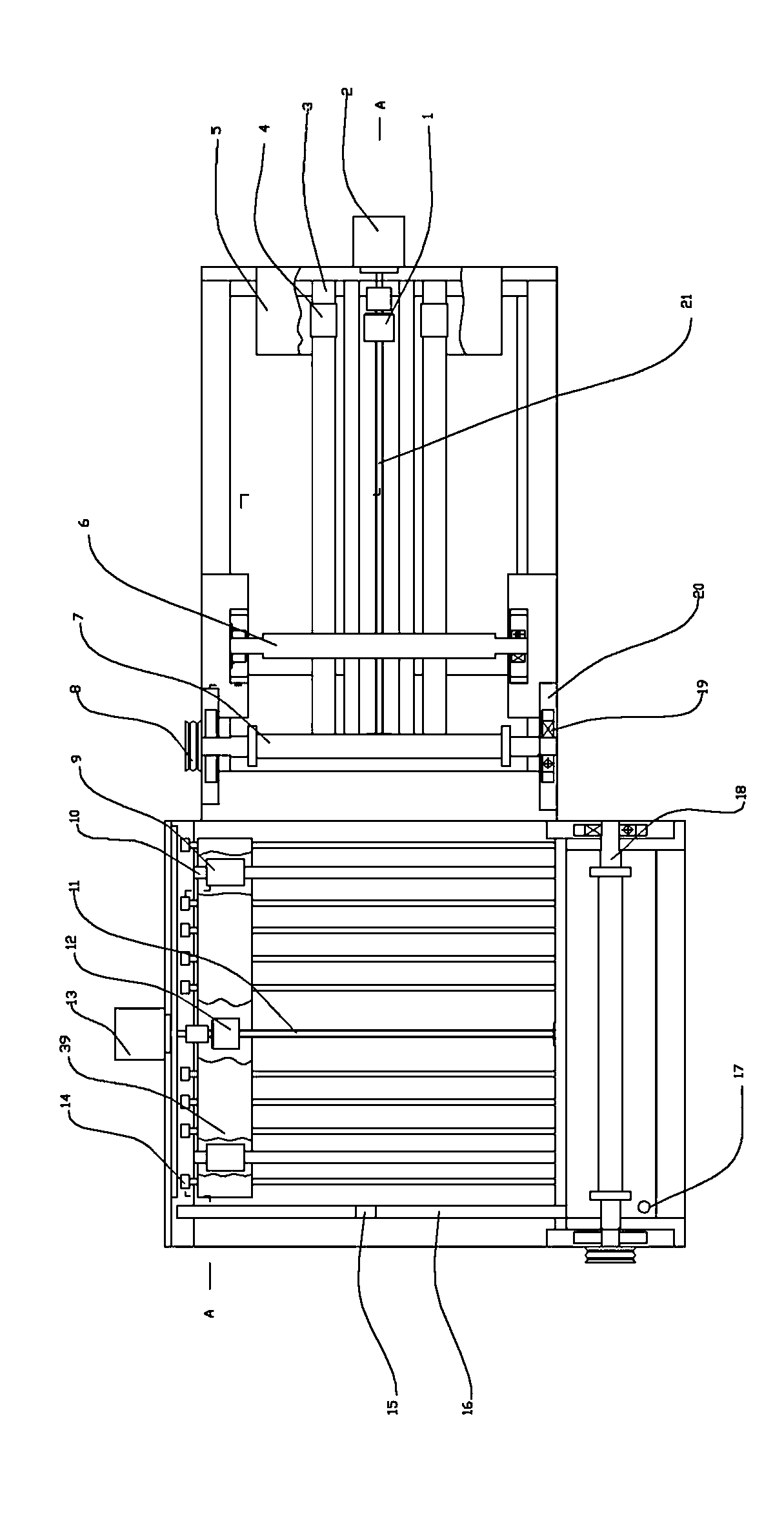

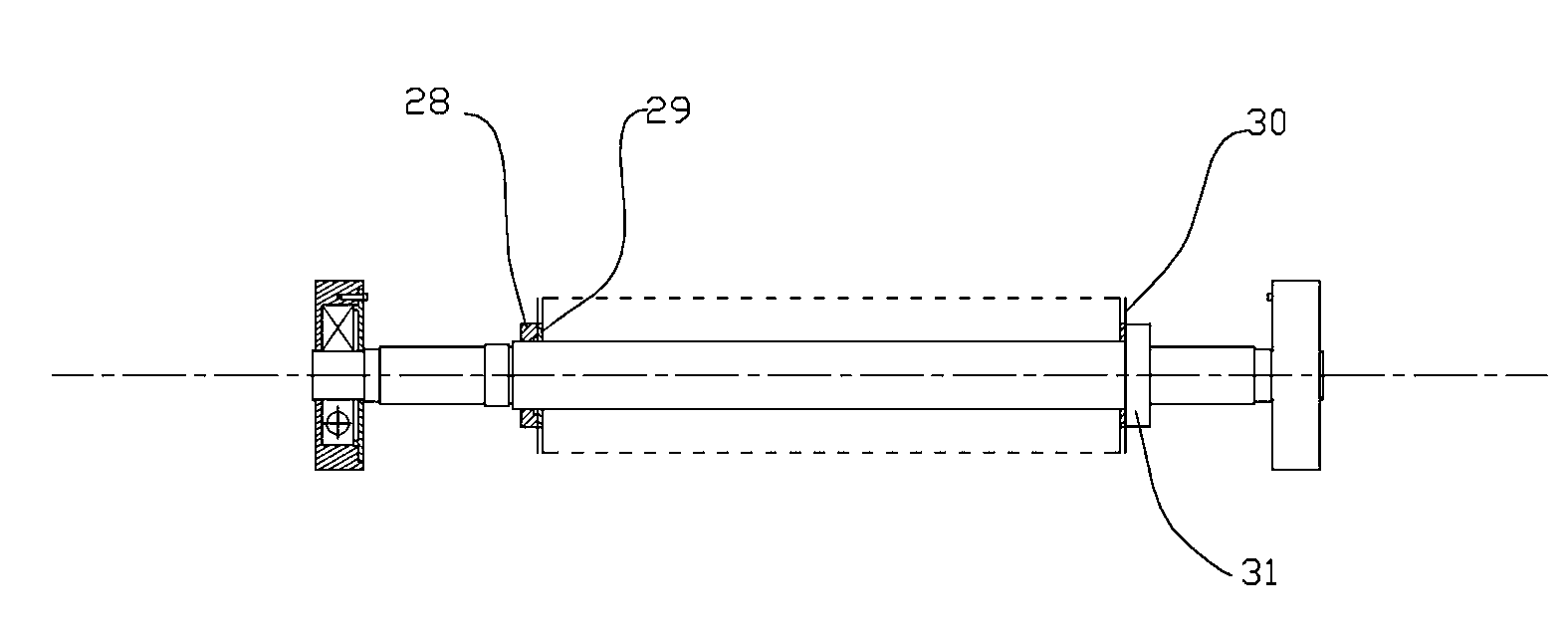

[0022] In the numerical control particle glass cutting machine provided by the present invention, the numerical control part is controlled by a programmable logic controller PLC, and the mechanical part includes an X-direction cutting mechanism and a Y-direction cutting mechanism. The X-direction cutting mechanism first cuts flat glass into strip-shaped glass strips , the Y-direction cutting mechanism further cuts the glass strips into granules. Such as figure 1 , figure 2 As shown, the X-direction cutting mechanism includes an X-direction workbench 22 supported by an X-direction frame. The middle part of the X-direction workbench 22 is provided with a horizontal guide groove 32 that penetrates up and down. An X-direction feeding stepper motor 2 is installed on the rack, and the output end of the X-direction feeding stepper motor 2 is matched with an X-direction ball screw 21 in the same direction as the transverse guide groove 32, and the X-direction ball screw 21 is The n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com