Drill chuck with two halves of split nuts with smooth engagement planes and manufacturing method of split nuts

A technology for splicing nuts and manufacturing methods, which is applied in the directions of nuts, manufacturing tools, connecting components, etc., can solve problems such as affecting the quality of drill chucks, not being well butted, affecting the quality of butting, etc., to improve flexibility and transmission efficiency. , The effect of eliminating the breaking process and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The specific implementation manner of the present invention will be described in detail below by means of drawings and examples.

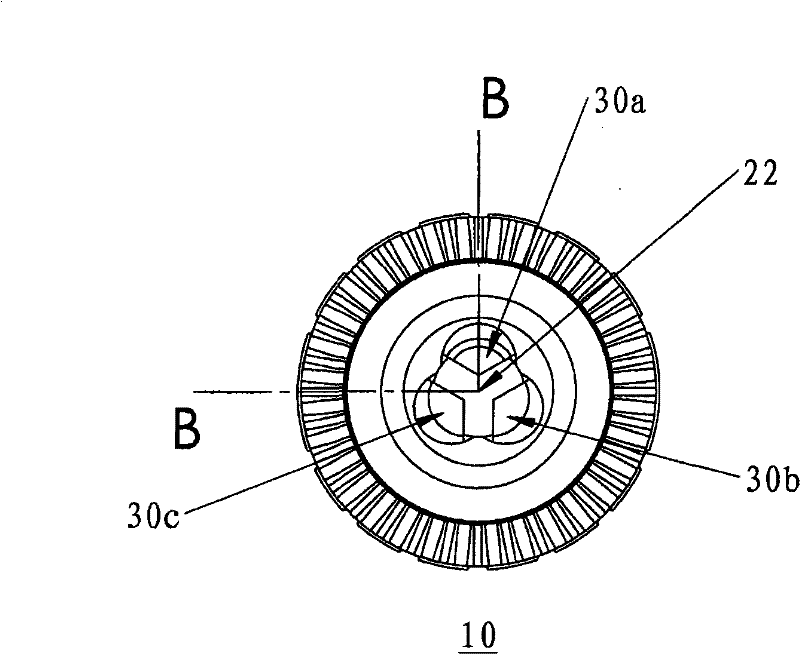

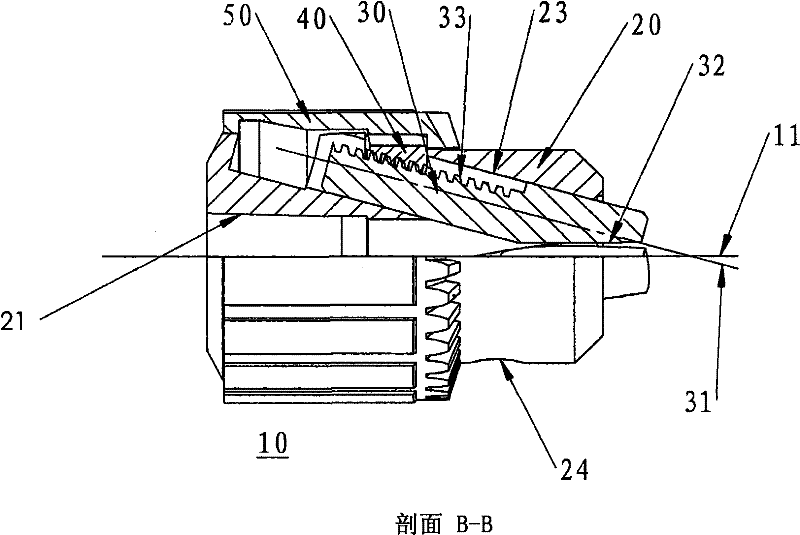

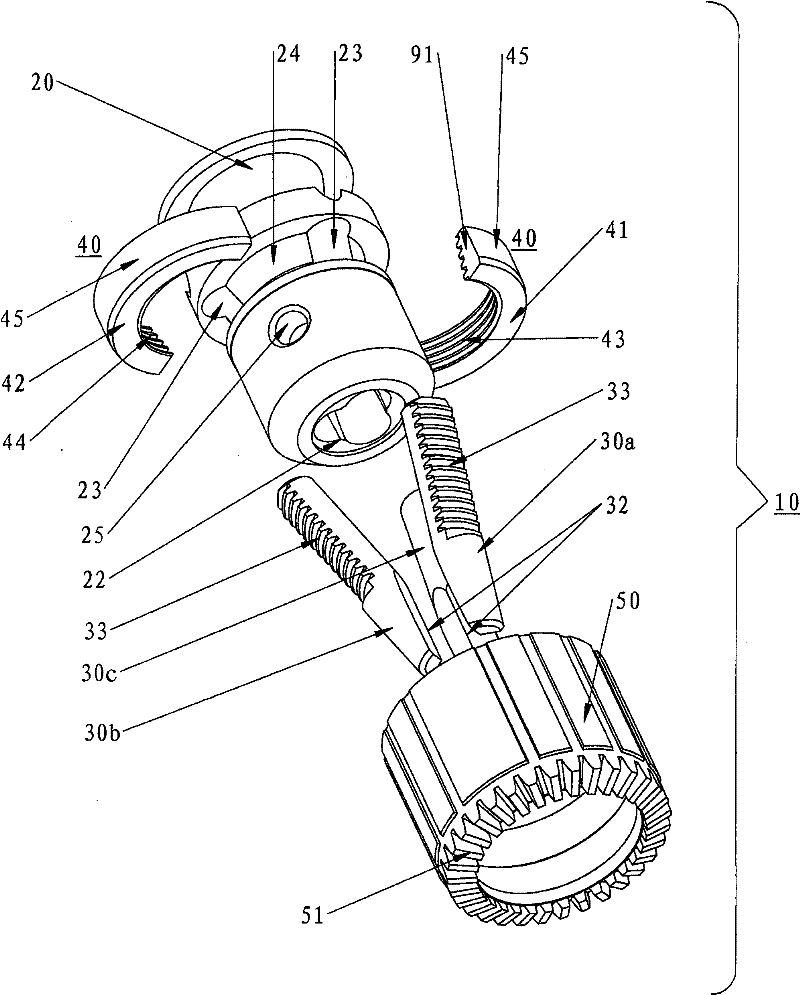

[0061] Take Figure 1 and figure 2 The drill chuck shown serves as a basis for illustrating the invention, Figures 1 and figure 2It is only an embodiment of a typical drill chuck, and the technical solution of the present invention will be embodied in the structure of the embodiment. The drill chuck can be improved according to the invention, that is, the invention is not limited to the embodiment of the drill chuck, and the solution of the invention can also be applied to drill chucks with or without keys of various existing designs. The following detailed descriptions are only carried out through examples, and are not meant to limit the protection scope of the present invention.

[0062] Figure 1, figure 2 , Figure 3C and Figure 3D As shown, the present invention provides a drill chuck 10 with two halves of a split nut with a smoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com