Thermal-spraying fuel spraying control system and control method capable of implementing fully closed-loop automatic control

A technology of automatic control and control system, applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of unable to form fully closed-loop automatic control, lack of ventilation and dust removal function, lack of shockproof structure, etc., to achieve convenient installation , easy to move, to ensure consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

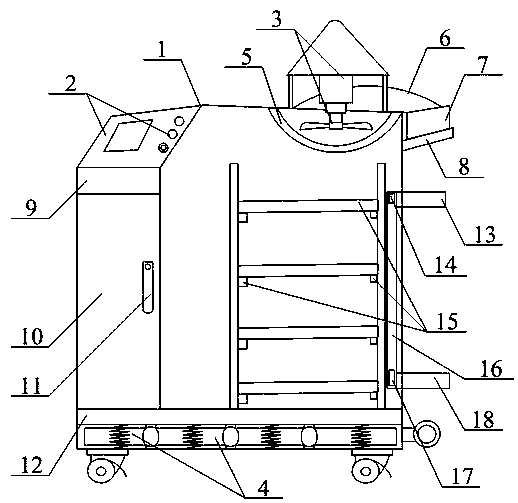

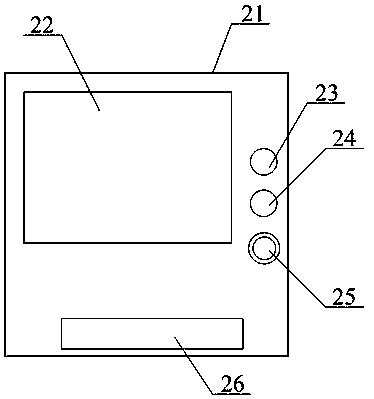

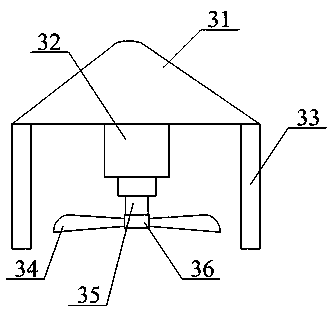

[0037] as attached figure 1 to attach Figure 5 shown

[0038]The present invention provides a thermal spraying fuel spraying control system and a control method of full-closed-loop automatic control, including a control cabinet 1, a full-closed-loop automatic control panel structure 2, a ventilation and dust removal fan structure 3, a shock-absorbing mobile seat structure 4, a protective cover 5, a guide Dust pipe 6, dust storage box 7, support seat 8, nameplate 9, cabinet door 10, link lock 11, support base 12, feed pipe 13, mass flow controller 14, shelf 15, feed pipe 16, The flow sensor 17 and the discharge pipe 18, the control cabinet 1 are bolted to the upper surface of the support base 12; the fully closed-loop automatic control panel structure 2 is bolted to the upper left side of the control cabinet 1; The ventilation and dust removal fan structure 3 is bolted to the right side of the upper surface of the control cabinet body 1; the shock-absorbing mobile seat struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com