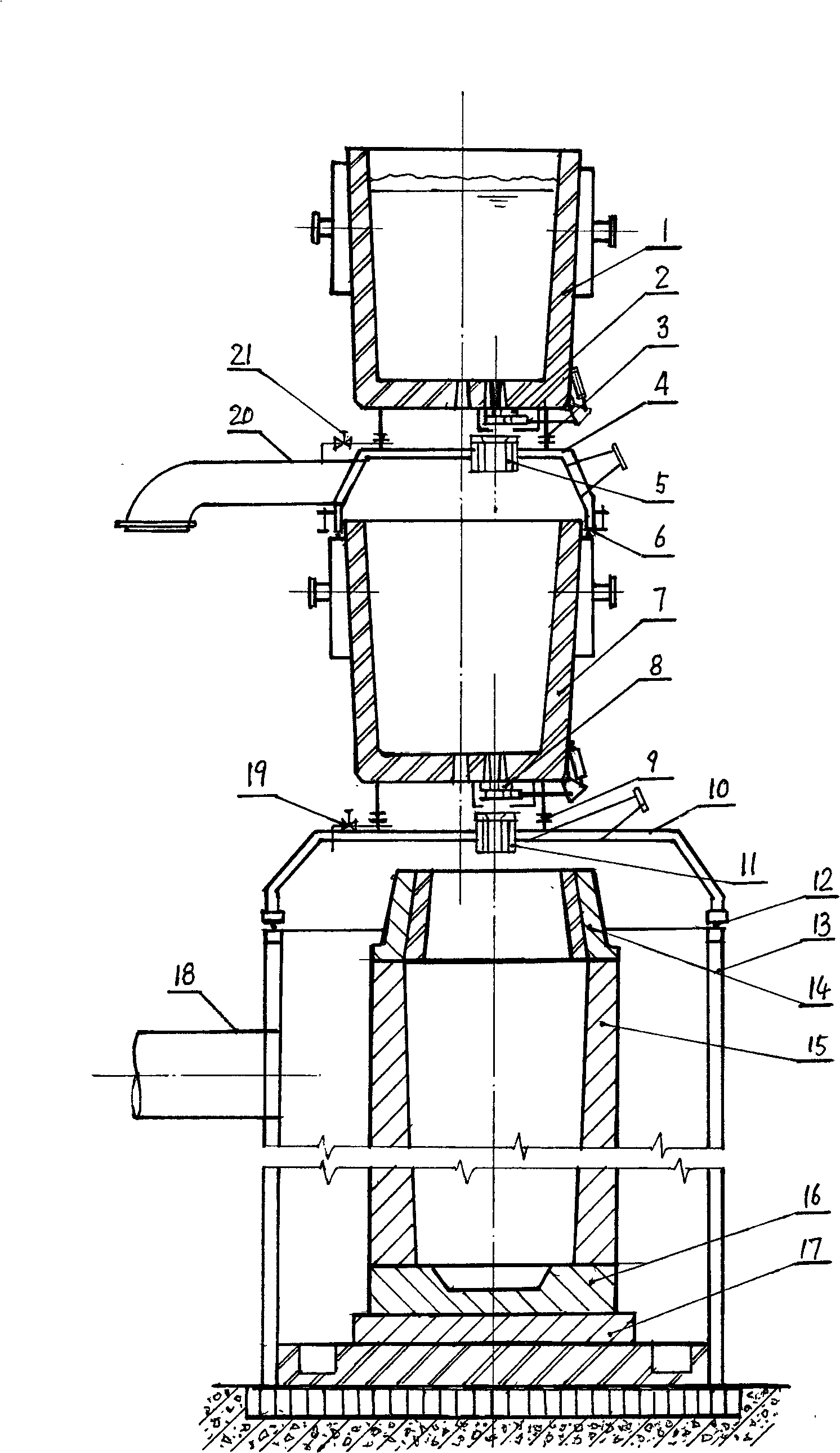

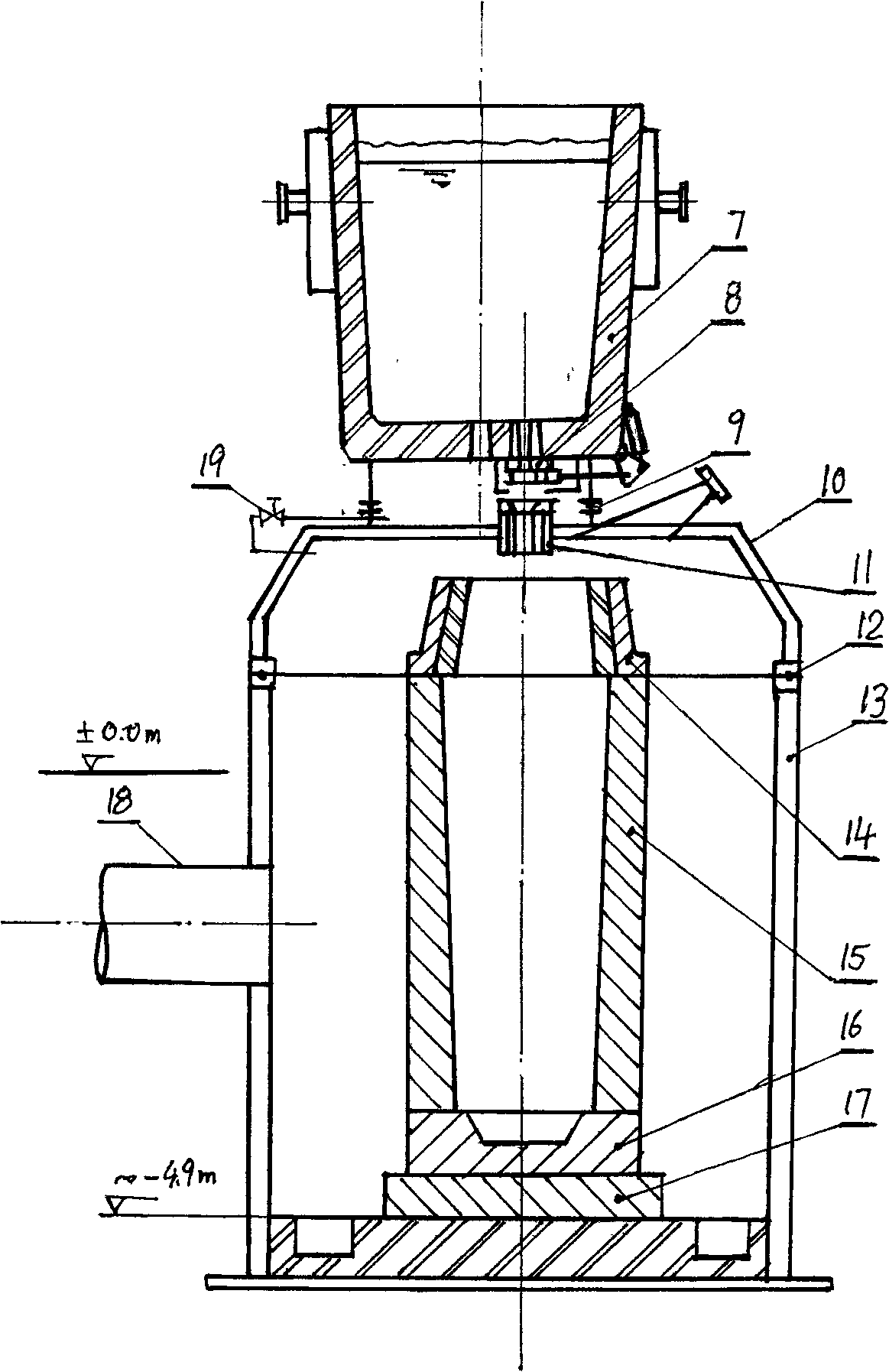

Equipment and technique for ladle-to-ladle, degasification and vacuum ingot casting of multiple-slide runner ladle

A technology of sliding nozzle and ladle, which is applied to equipment, casting equipment, metal processing equipment, etc. for feeding molten metal into casting molds, can solve problems such as prolonging casting time, and achieve the effect of simplifying equipment and simplifying process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0145] I think the preferred way to implement the present invention is

[0146] 1 Preliminary comparative test

[0147] The comparative test of "directly vacuum casting a 100t large steel ingot from a package of undegassed molten steel after refining" was carried out in the steelmaking branch of Juki Enterprise with 100-ton LF refining, VD degassing and vacuum ingot casting equipment

[0148] 1.1 Using the existing vacuum ingot casting technology: the sliding nozzle ladle containing 100 tons of refined and undegassed molten steel is poured into the plug rod type tundish in the atmosphere, and then the plug rod is opened to vacuum the 100t large steel ingot mold in the vacuum chamber A hundred-ton ingot was cast.

[0149] 1.2 Adopt the process plan (i.e. 2.2.3 process plan) proposed by me of "directly vacuum casting a large steel ingot with a sliding nozzle ladle of molten steel after refining", cancel the stopper-type tundish, and the ladle sits on the vacuum chamber cover ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com