Tundish with baffle wall for vacuum cast ingot

A tundish and slag retaining weir technology, used in foundry equipment, casting melt containers, metal processing equipment, etc., can solve the problems of short residence time, unreasonable temperature distribution, affecting product quality, etc., to increase residence time, promote The effect of floating inclusions and reducing the probability of slag entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

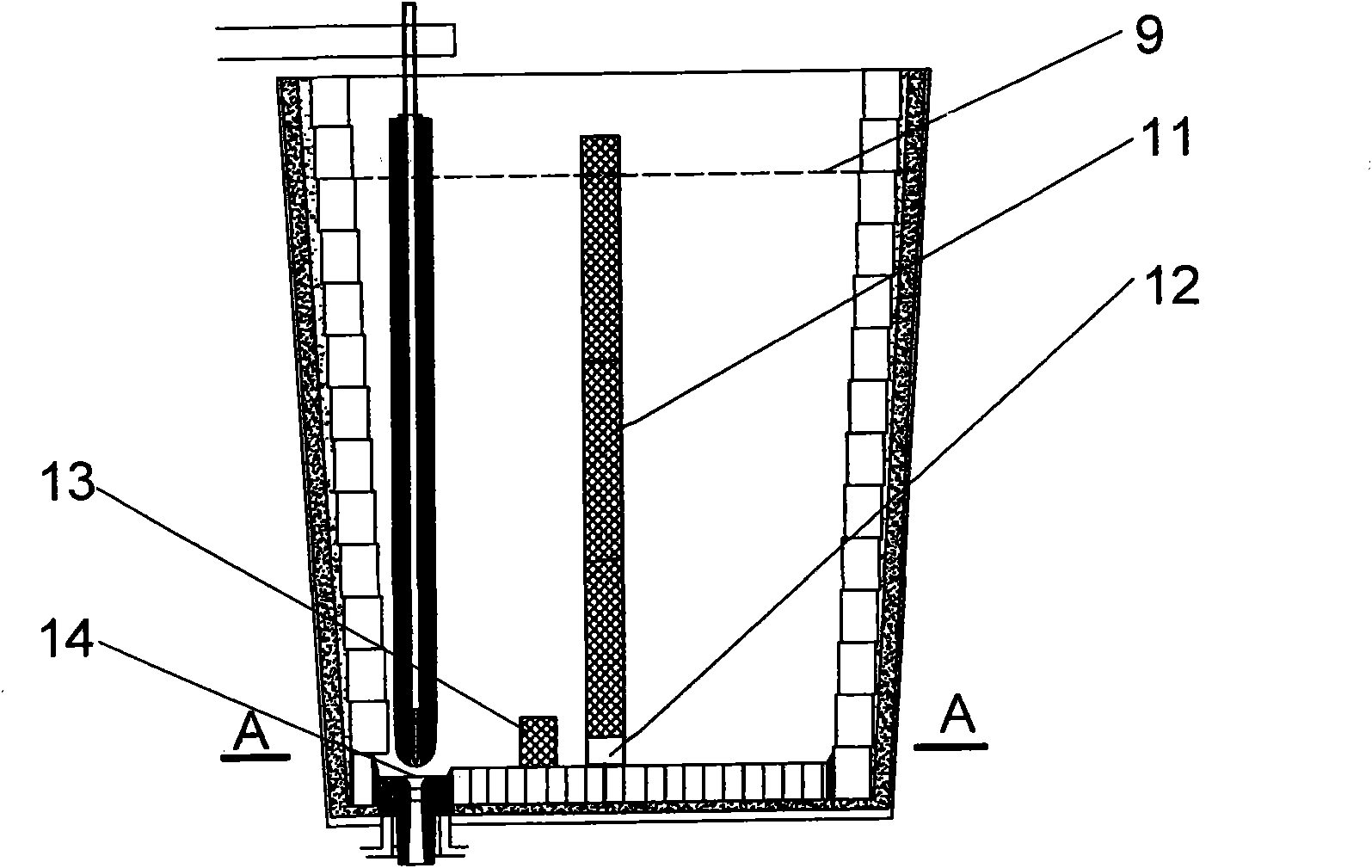

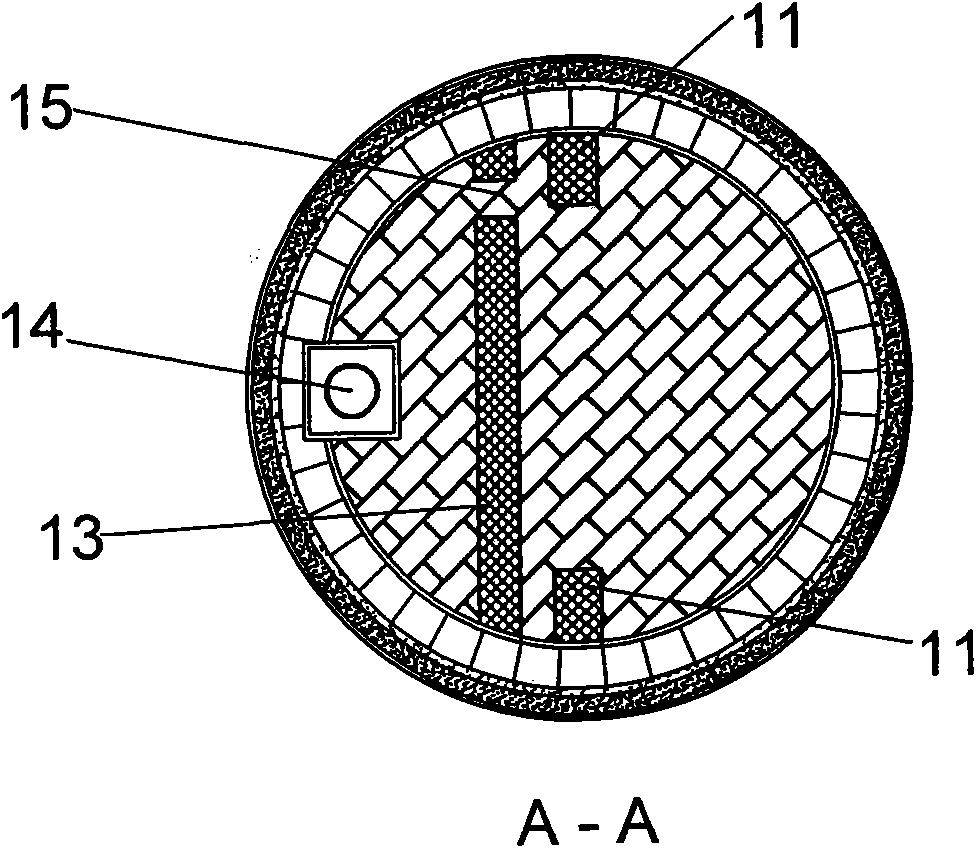

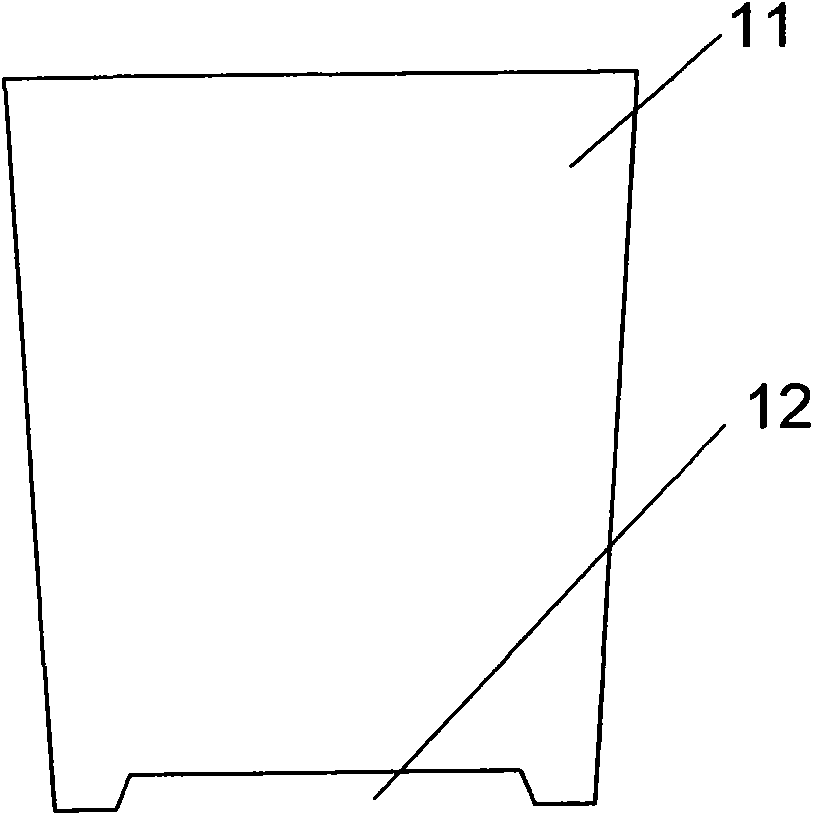

[0028] like figure 1 As shown, the structure of the tundish for vacuum ingot casting with a slag retaining weir of the present invention is that a slag retaining weir 11 is provided in the tundish, a steel passage 12 is provided at the bottom of the slag retaining weir 11, and the tundish The nozzle 14 is located on one side of the slag retaining weir 11 , the pouring steel inlet is located on the other side of the slag retaining weir 11 , and the height of the slag retaining weir 11 is greater than the liquid steel surface 9 . Wherein, the structure of the slag retaining weir 11 is as follows: image 3 As shown, that is, the slag retaining weir 11 is a "door" type slag retaining weir 11, the lower end of the slag retaining weir 11 extends to the bottom of the tundish on both sides, and a steel passage 12 is provided in the middle, and on the side of the nozzle 14 A diversion dam 13 is arranged on the bottom surface of the tundish, and the diversion dam 13 is higher than the ...

Embodiment 2

[0033] Another embodiment of the present invention is as Figure 5-7 As shown, the same reference numerals are used for the same parts as in the first embodiment.

[0034] Compared with the first embodiment above, this embodiment differs in that the structure of the slag retaining weir 111 is different.

[0035] like Figure 7 As shown, in this embodiment, the slag weir 111 of the tundish for vacuum ingot casting with a slag weir is a trapezoidal slag weir 111, and the bottom of the slag weir 111 is flush, and the Bottom surface offers steel channel 12.

Embodiment 3

[0037] Figure 8-10 Still another embodiment of the present invention is shown.

[0038] The structure of the tundish for vacuum ingot casting with a slag retaining weir in this embodiment is that a slag retaining weir 21 is arranged in the tundish, a steel passage 22 is provided at the bottom of the slag retaining weir 21, and a tundish nozzle 24 It is located on one side of the slag weir 21, and the pouring steel inlet is located on the other side of the slag weir 21. The height of the slag weir 21 is greater than the liquid steel level 9, and the lower end of the slag weir 21 extends to the bottom of the tundish. The slag weir 21 is at a certain distance from the bottom of the tundish, and there is a steel passage 22. The opening of the steel passage 22 on the pouring side is lower than the opening of the steel passage 22 on the nozzle 24 side, and the molten steel flows through the steel passage. Behind the channel 22, an oblique upward flow field is formed.

[0039] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com